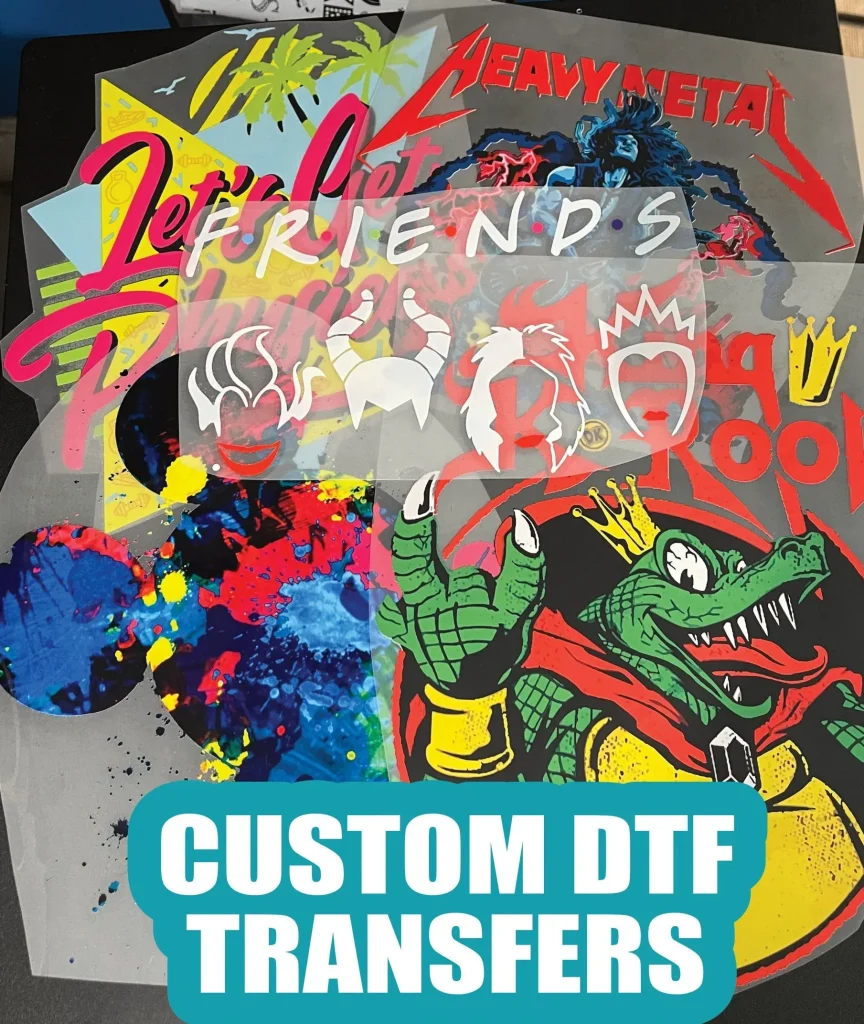

In the dynamic realm of textile printing, **DTF Transfers** stand out as a cutting-edge innovation that merges quality and convenience. This unique process leverages Direct-to-Film printing technology, allowing intricate designs to be transformed into vibrant textiles with ease. As we delve into the benefits of DTF transfers, it becomes clear why they are rapidly becoming a go-to method for custom apparel and promotional items. This guide will illuminate the DTF printing process, highlight its various applications, and showcase how this textile printing technology can enhance your design projects. Discover the endless possibilities that DTF transfers offer for both personal and commercial ventures.

In the textile printing industry, one of the most exciting advancements is the technique known as Direct-to-Film Transfers, often referred to by enthusiasts simply as DTF transfers. This innovative process involves applying artwork onto a specialized film before transferring it to fabric, enabling a broad range of applications from fashion to promotional materials. The appeal of DTF lies not only in its efficiency but also in the high-resolution quality of prints it produces, making it a valuable tool for artists and manufacturers alike. Whether you refer to it as the DTF printing method or a form of fabric transfer technology, its benefits continue to inspire users across various creative fields, reinforcing its status as a game-changer in the realm of custom textile designs.

Understanding the DTF Printing Process

The DTF printing process begins with crafting a unique design, usually done via graphic design software. This design must meet high-resolution standards to ensure that the final output on fabric is crisp and clear. After the design is finalized, it is printed onto a specialized DTF film using a DTF printer. This printer utilizes unique inks that are pivotal in adhering to the transfer film, setting the stage for the next crucial steps in the transfer process.

Following the printing, a hot melt powder is applied to the wet ink. This powder plays an essential role in the transfer process, adhering tightly to the ink. Once the powder is applied, the film undergoes a curing process, where it is subjected to heat to ensure a strong and durable bond between the powder and ink. This stage is vital for producing transfers that can withstand the rigors of washing and wearing.

Benefits of DTF Transfers in Textile Printing

DTF transfers offer a multitude of benefits that make them a preferred choice in textile printing. One of the primary advantages is the high-quality prints they yield. The DTF printing method is capable of delivering vibrant colors and intricate detail, which is essential for graphic designs that aim to catch the eye and convey a message effectively. This quality is particularly beneficial for businesses looking to create standout promotional items or custom apparel.

In addition to their quality advantage, DTF transfers are highly versatile. They can be applied to a wide array of fabrics including cotton, polyester, and blends, making them suitable for a variety of creative projects. This adaptability opens numerous opportunities not just in the fashion industry, but also in promotional merchandise and personalized gifts, allowing users to express creativity without constraints.

Ease of use is another significant benefit; DTF printing is less complicated than many traditional textile printing methods, requiring minimal preparation time. This ease of use allows businesses to quickly pivot and fulfill clients’ requests, thereby increasing efficiency and productivity in operations.

Applications of DTF Transfers in Fashion and Business

The applications of DTF transfers extend widely across various sectors, particularly in fashion and business. Custom apparel is a significant area where DTF printing shines. Whether it’s T-shirts, hoodies, or other clothing items, DTF technology allows for tailor-made designs that can resonate with personal style or brand identity. This capability is crucial for outfitters who provide unique, one-of-a-kind pieces to customers.

Beyond personal apparel, DTF transfers are also extremely popular in creating promotional merchandise. Businesses often seek customizable products for giveaways, events, or branding initiatives. The ability to produce high-quality designs at scale enables companies to leave a memorable impression on their customers, thus enhancing marketing efforts and facilitating customer engagement.

Comparing DTF Printing with Other Textile Printing Technologies

When considering various textile printing technologies, DTF printing distinguishes itself with its efficiency and print quality compared to methods like screen printing and direct-to-garment (DTG) printing. For instance, while screen printing can become cost-prohibitive at small quantities due to setup times and cost of screens, DTF printing offers a more economical solution for smaller runs without sacrificing quality.

Additionally, the simplicity of DTF versus DTG is evident. DTF does not require pre-treatment of fabrics, allowing for a more streamlined process. This characteristic not only reduces preparation time considerably but also minimizes production delays, providing a competitive edge for businesses eager to meet tight deadlines.

Challenges and Considerations for DTF Transfers

While DTF transfers present significant benefits, it’s essential to acknowledge their challenges. One notable concern is the removal process; improper techniques for removing DTF prints can damage the underlying fabric. This issue indicates the necessity for users to familiarize themselves with correct removal practices to maintain garment integrity.

Moreover, the initial investment for setting up DTF printing systems can be higher compared to other printing alternatives, particularly for those new to the industry. Entrepreneurs and small business owners should weigh these costs against potential returns on investment, especially given the quality and versatility benefits of DTF technology.

Exploring the Future of DTF Transfers in the Textile Industry

As technology in textile printing continues to evolve, DTF transfers are anticipated to play an increasingly vital role. Innovations in DTF printing technology, such as improved inks and application methods, are being developed to enhance the user experience further. With advancements underway, we can expect DTF printing to become even more efficient and accessible, widening its appeal to a broader audience.

In summary, the future of DTF transfers looks promising as they forge new paths for creativity and customization within the textile industry. Continuous learning, staying updated on trends, and applying innovative approaches will empower users to harness DTF technology’s full potential, leading to exciting opportunities in garment printing and design.

Frequently Asked Questions

What are DTF Transfers and how do they work?

**DTF Transfers**, or Direct-to-Film Transfers, involve printing designs onto a special film which is then heat transferred to textiles. This process uses a DTF printer to create high-quality prints, allowing for vibrant colors and detailed designs on various fabric types without pre-treatment.

What are the benefits of DTF Transfers compared to traditional printing methods?

The benefits of **DTF Transfers** include vibrant colors, fine detail reproduction, and versatility across different fabric types like cotton and polyester. Additionally, DTF does not require pre-treatment of fabric, simplifying the printing process and reducing preparation time.

Which applications are best suited for DTF Transfers?

**DTF Transfer applications** are diverse, including custom apparel, promotional items, and personalized gifts. This printing technology is ideal for creating unique t-shirts, hoodies, and branded merchandise for events and marketing campaigns.

How long do DTF Transfers last after application?

When properly applied and cared for, **DTF Transfers** can last through many washes without significant fading or peeling. Adhering to proper washing instructions is crucial for maintaining the longevity of the prints.

What equipment is necessary for DTF printing?

To get started with **DTF printing**, you will need a DTF printer, special inks, DTF transfer film, hot melt powder, and a heat press. Investing in quality equipment ensures high-quality results and effective production.

Can DTF Transfers be applied to all fabric types?

**DTF Transfers** are compatible with various fabric types, predominantly cotton and polyester. While some blends may work, it is recommended to test the fabric compatibility to ensure successful transfer.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | DTF transfers utilize a printing process involving a specialized film and heat to transfer designs onto textiles. |

| Pros of DTF Transfers | High-quality prints, versatility across fabric types, and ease of use. |

| Cons of DTF Transfers | Challenges in removal from fabric and higher initial setup costs. |

| How DTF Transfers Work | Involves design creation, printing on film, powder application, curing, and transferring to fabric. |

| Applications of DTF Transfers | Popular in custom apparel, promotional merchandise, and personalized gifts. |

Summary

DTF Transfers denote an innovative technique in fabric and textile printing that combines efficiency with quality. This method allows for high-resolution designs to be printed on a range of fabrics, making it perfect for custom clothing and promotional items. Despite challenges such as removal techniques and initial investment costs, the overall advantages presented by DTF Transfers—such as versatility and ease of application—make them a compelling choice for both businesses and creative enthusiasts. As technology advances, the appeal and accessibility of DTF printing are anticipated to grow, ushering in a new age of textile design opportunities, ensuring your projects can truly stand out.