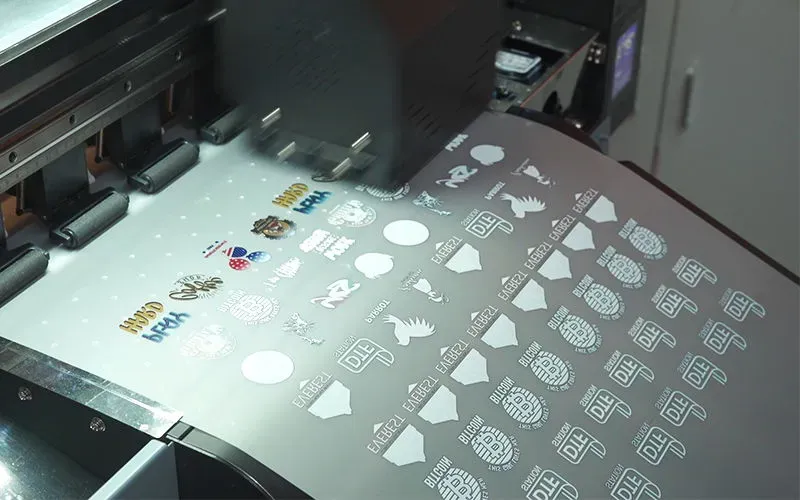

Building Gangsheet with DTF Technology has revolutionized the landscape of custom apparel printing. This innovative approach leverages Direct-to-Film (DTF) printing to create a gangsheet, which allows for the simultaneous printing of multiple designs on one film. Not only does this method reduce waste, but it also enhances efficiency, making it a favorite among designers and businesses aiming for high-quality outputs. In this guide, we will take you through the essential steps in gangsheet creation, from initial design preparation to the final heat transfer printing process. With the right knowledge and techniques, employing DTF technology can transform your custom apparel production into a streamlined operation.

Exploring the art of producing a gangsheet via Direct-to-Film (DTF) technology reveals a myriad of possibilities in the world of printed textiles. This advanced printing method captures the essence of heat transfer printing, enabling creators to layer various graphics onto a single sheet, which maximizes material efficiency. By mastering the intricacies of gangsheet creation, you can not only save on resources but also bring artistic visions to life in vibrant colors and stunning details. The fusion of innovative printing techniques with the practical application in custom apparel makes this process highly sought after. Join us as we delve deeper into the processes and strategies for effectively building your first gangsheet.

Exploring the Essentials of DTF Printing

Direct-to-Film (DTF) printing stands as a revolutionary method for creating stunning designs on varying substrates. This technique allows artists and businesses alike to print high-resolution images directly onto a special film that can be later transferred to fabrics such as cotton, polyester, and blends. By utilizing vibrant inks and a unique adhesive process, DTF printing ensures that the final product maintains excellent color fidelity and durability, essential for custom apparel applications.

Understanding the nuances of DTF printing is pivotal for anyone involved in the custom apparel industry. Unlike traditional methods, DTF stands out due to its ability to produce multiple designs at once, significantly saving time and material costs. This characteristic not only enhances productivity but also improves your ability to cater to diverse client requests, thus opening up a wider market niche.

The Importance of Gangsheet Creation in DTF

Building a gangsheet with DTF technology maximizes efficiency in printing by allowing multiple designs to be laid out on a single piece of film. This strategic approach not only reduces waste but also streamlines the production process, making it a cost-effective solution for businesses focused on custom apparel. By effectively planning your gangsheet, you can ensure that you make the most out of your materials while delivering high-quality prints to your customers.

Additionally, gangsheet creation helps in tackling the common issue of design sizing and spacing. By carefully arranging your designs, you can eliminate unnecessary gaps and ensure that each image prints to its full potential. This careful consideration of layout will contribute to a more professional finish and can significantly enhance client satisfaction.

Design Preparation for Effective Gangsheet Layouts

The design preparation phase is crucial when creating your gangsheet for DTF printing. Using graphic design software like Adobe Illustrator or CorelDRAW, you have the tools necessary to ensure that your designs are not only visually appealing but also optimized for printing. Paying attention to resolution, color settings, and dimensioning will make a noticeable difference in the quality of the final product.

When arranging your layouts, consider not just the aesthetic, but also the practical aspects such as the size of the material being used. Understanding the dimensions and limitations of your film will allow you to effectively utilize each inch, ensuring that no material goes to waste. A well-prepared design layout translates directly to a more efficient production process.

The Printing Process Explained: From Film to Fabric

The printing process in DTF technology involves several detailed steps that are critical for success. After you’ve set up your designs and ensured your printer is adequately equipped with the right inks and films, the quality of the print largely depends on your printer settings. Factors such as ink saturation, resolution, and print speed contribute significantly to the outcome — therefore, meticulous adjustments and tests are recommended.

Once your designs have been printed onto the film, the subsequent application of an adhesive powder serves as an essential step in the heat transfer process. This powder helps to ensure that the designs adhere securely to the fabric, creating a long-lasting print that withstands washes and wear. Managing this step effectively is key to producing high-quality custom apparel.

Curing Adhesive for Optimal Transfer Quality

Curing the adhesive is a pivotal step in achieving a successful heat transfer during the DTF printing process. By placing the printed film in a curing oven, you can activate the adhesive, which bonds with the ink to create a robust transfers. Typically, curing requires precise temperature settings and timing, as each type of fabric may react differently, which underscores the importance of following manufacturer guidelines for best results.

An effective curing process not only enhances the adherence of the design to the fabric but also improves the vibrancy of printed colors. When executed correctly, it significantly elevates the overall quality of your prints, ensuring they stand out in the competitive world of custom apparel and printing techniques.

Mastering the Heat Transfer Technique

The heat transfer phase is where the transition from design to finished product occurs, and mastering this step is crucial for success with DTF technology. Proper alignment of the film on the garment, along with setting the right parameters on your heat press, is key. Typically, a standard temperature range of around 320°F (160°C) for about 10-15 seconds yields optimal results.

It’s vital to maintain adequate pressure during the heat application phase to ensure that the design adheres properly and evenly across the fabric. Neglecting this can result in areas where the image might not stick, detracting from the overall quality of your work. Understanding the dynamics of different fabric types can also help you adjust your settings for the best outcome, further optimizing your gangsheet creations.

Frequently Asked Questions

What is the process of building a gangsheet with DTF technology?

Building a gangsheet with DTF technology involves several steps: first, create high-resolution designs using graphic design software like Adobe Illustrator. Next, arrange your designs efficiently on a film layout to optimize space. After exporting your layout, you print it using a DTF printer, apply adhesive powder, cure the adhesive, and finally perform heat transfer to your chosen garment. This process minimizes material waste while maximizing efficiency in custom apparel production.

How does DTF printing enhance gangsheet creation for custom apparel?

DTF printing enhances gangsheet creation for custom apparel by allowing multiple designs to be printed simultaneously on one film sheet. This technique not only reduces material costs but also speeds up the printing process. The versatility of DTF printing means that designs can be transferred onto various fabrics with high-quality results, making it an ideal choice for businesses looking to produce custom apparel at scale.

What materials are best for building gangsheet with DTF technology?

When building a gangsheet with DTF technology, the best materials to use include high-quality transfer film specifically designed for DTF printing, DTF inks, and suitable adhesive powder. It’s also essential to select compatible fabrics for the heat transfer process; cotton, polyester, and blends generally work well for vibrant and durable prints. Ensure all materials are designed to perform well under the heat press to achieve optimal results.

What are the advantages of using gangsheet creation in DTF printing?

The advantages of using gangsheet creation in DTF printing include reduced wastage of film and materials, the ability to print multiple designs at once, and significant savings on production costs. Additionally, gangsheet creation allows for greater flexibility and customization options, enabling designers to cater to diverse customer orders without the need for separate runs for each design.

Can I use DTF printing for small batch operations in gangsheet creation?

Yes, DTF printing is well-suited for small batch operations in gangsheet creation. Its efficient printing and heat transfer process makes it possible to produce limited runs of custom apparel without incurring high costs. Whether for small businesses or individual projects, DTF technology allows for high-quality prints and detailed designs on demand, making it ideal for small-scale production.

What settings should I use when heat pressing DTF gangsheet prints?

When heat pressing DTF gangsheet prints, typical settings include a temperature of around 320°F (160°C) for 10-15 seconds, depending on the fabric type. Adequate pressure is crucial for ensuring proper adhesion between the DTF print and the garment. It’s essential to follow the manufacturer’s guidelines for both the DTF printer and the heat press to achieve durable and vibrant results.

| Step | Description | Key Points |

|---|---|---|

| 1 | Understanding DTF Printing | Learn about the versatility of DTF printing and its application in custom apparel. |

| 2 | The Concept of a Gangsheet | A gangsheet minimizes waste while accommodating multiple designs on one sheet. |

| 3 | Design Preparation | Use graphic design software to create, layout, and export designs for printing. |

| 4 | Printing the Film | Set up your printer correctly and pay attention to color quality settings during printing. |

| 5 | Applying Adhesive Powder | Evenly sprinkle adhesive powder over the ink to ensure proper adhesion during transfer. |

| 6 | Curing the Adhesive | Cure the film for 1-2 minutes to activate the adhesive for a durable transfer. |

| 7 | Heat Transfer | Apply heat and pressure to transfer the design onto the garment effectively. |

| 8 | Cooling and Peeling | After cooling, carefully peel the film off to reveal the printed design. |

Summary

Building a gangsheet with DTF technology is a pivotal process in the realm of custom apparel, allowing numerous designs to be printed simultaneously while minimizing waste. This method not only streamlines material usage but also offers an effective solution for those aiming to scale their printing operations. By meticulously following the outlined steps—from understanding DTF and preparing designs, to printing and heat transferring—you can maximize both efficiency and quality. Engaging with DTF technology opens up exciting possibilities for customized prints, making it an essential technique for aspiring entrepreneurs and established businesses alike.