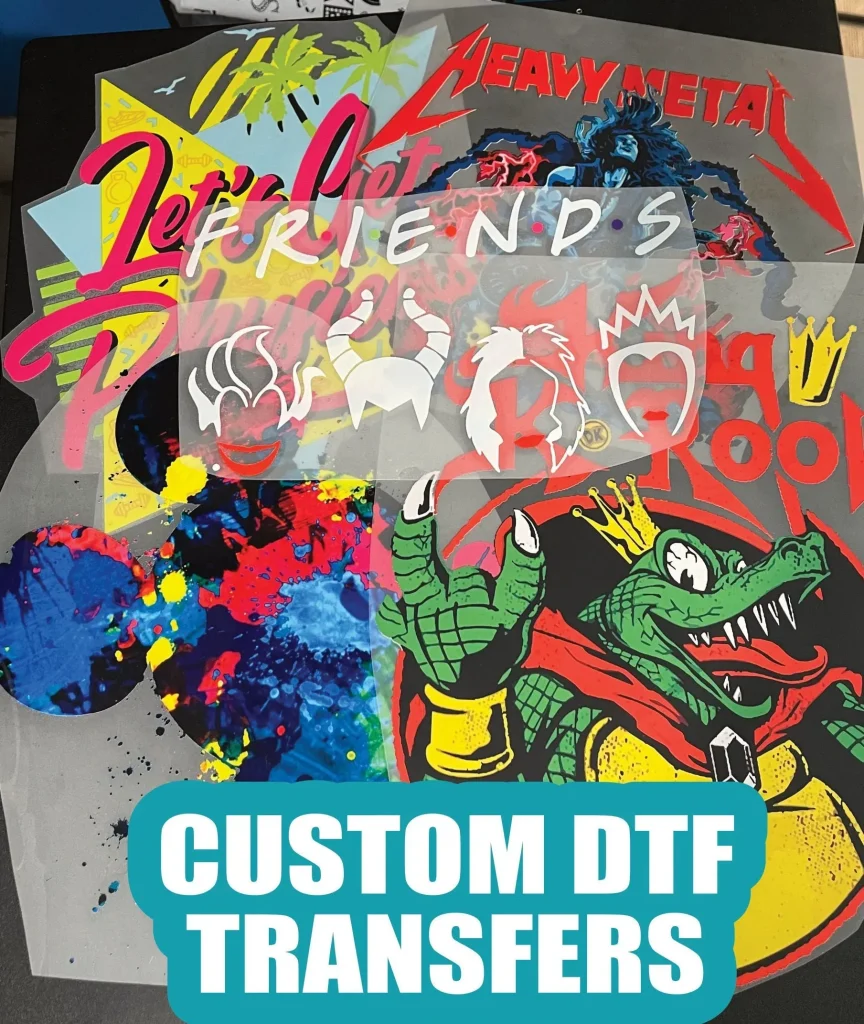

DTF Transfers, or Direct to Film transfers, have rapidly become a game-changer in the world of custom apparel printing. This innovative printing method allows for the vibrant reproduction of intricate designs, adhering seamlessly to a variety of fabrics, making it a favorite among garment decorators. With the DTF printing process, you can achieve superior color depth and durability, ensuring your designs stand the test of time against wear and washing. In this introductory guide, we’ll delve into the benefits of DTF transfers, how they revolutionize custom apparel printing, and the straightforward steps to use them effectively. Whether you’re a seasoned printer or just starting, understanding DTF transfers is essential for enhancing your creative projects.

Also known as Direct to Film printing, this contemporary method has transformed the landscape of custom garment creation. By applying designs onto special films before transferring them onto various textiles, the DTF approach presents a versatile solution for apparel decorators. From its ability to produce vibrant and long-lasting images to the ease of use involved in the DTF printing process, alternative terms like film transfer printing capture the essence of this method. The advantages of DTF are numerous, particularly for those looking to expand their custom printing capabilities. As we explore further, you’ll see how DTF transfers empower creativity and innovation in the apparel industry.

Understanding DTF Transfers: An Overview

Direct to Film (DTF) transfers represent a groundbreaking advancement in custom apparel printing. Unlike traditional methods that apply designs directly to fabric, DTF utilizes a specially coated film as its medium. This process begins with printing a high-resolution image onto the DTF film, which is pivotal for ensuring the vibrancy and detail that are characteristic of DTF prints. After printing, a hot-melt adhesive powder is sprinkled onto the film before heat is applied to cure it, preparing the design for transfer. This method enhances the print’s durability, making it resilient to washing and wear.

The versatility of DTF transfers is another crucial aspect worth highlighting. This printing technique is compatible with a broad array of materials, including cotton, polyester, and blends, which means apparel businesses can produce a variety of custom products without being limited to specific fabrics. Therefore, whether you are creating t-shirts, hoodies, or sportswear, DTF transfers can easily accommodate your needs, expanding your capabilities in the fashion marketplace.

Key Advantages of DTF Printing

DTF printing offers numerous advantages that set it apart from other traditional printing methods. One of its most notable benefits is its impressive durability. Once transferred, DTF designs adhere firmly to the fabric, allowing the prints to resist fading, cracking, and peeling over time. This durability is especially advantageous for businesses looking to produce quality apparel that can stand the test of time, thus offering better value to customers.

Moreover, DTF transfers are renowned for their superior color vibrancy. The DTF printing process can reproduce intricate designs with a depth of color and detail that is often unmatched by other methods, leading to visually stunning products. This rich expression of color is crucial in attracting clientele in the competitive fashion industry, as vibrant designs often convert better into sales.

Step-by-Step Guide on DTF Printing Process

Embarking on the DTF printing journey requires an understanding of its essential steps. First and foremost is the creation of your digital design, which should ideally be of high resolution to ensure the outcome meets your quality expectations. Following this, you’ll need to print your image onto the DTF film using a specialized DTF printer. The quality of your printer will significantly affect the overall print output, making this step foundational for a successful process.

Once the image is printed, applying an adhesive powder is the next critical phase. This hot-melt adhesive is what ultimately bonds the design to the fabric. After applying the adhesive, it’s time for the heat transfer, which involves placing the film on the garment and applying heat using a heat press. This step activates the adhesive, ensuring a strong, lasting bond between the ink and the fabric.

Best Practices for Successful DTF Printing

To achieve optimal results in DTF printing, several best practices are recommended. First, investing in quality equipment cannot be overstated. Selecting a reliable DTF printer and heat press will substantially impact your production quality, making the upfront investment worthwhile. Quality machinery often leads to fewer technical issues and higher customer satisfaction.

Utilizing graphic design software is another best practice that can help enhance your DTF printing workflow. Software like Adobe Photoshop or Illustrator allows for careful design adjustments that can significantly improve the final print clarity and vibrancy. Additionally, conducting test prints prior to larger orders can help identify any potential issues, allowing you to perfect your process and ensure your final products meet the intended standards.

Market Trends Influencing DTF Transfers

The landscape of custom apparel printing is evolving, with DTF transfers at the forefront of this change. Current market trends indicate a growing preference for printing methods that offer lower barriers to entry, such as DTF printing, which does not require extensive equipment investments or specialized skills to operate successfully. This shift has opened opportunities for small businesses and entrepreneurs to enter the custom apparel market more easily.

As businesses increasingly seek cost-effective and versatile printing solutions, DTF can provide a compelling option. Its adaptability to various fabric types and ability to produce durable products means it can cater to a wider audience, from small local businesses to larger fashion brands. Adopting DTF transfers not only meets current market demands but also positions businesses favorably for future growth.

Additional Resources for Mastering DTF Printing

For those interested in further enhancing their knowledge of DTF printing, a plethora of resources exists to guide beginners and experienced printers alike. Websites dedicated to printing, forums discussing the latest techniques, and video tutorials on platforms like YouTube provide invaluable insights into mastering the DTF process. These resources are excellent for learning about specific tips and tricks that can streamline your printing workflow.

Additionally, engaging with online communities that focus on DTF enthusiasts can be incredibly beneficial. By participating in discussions, asking questions, and sharing experiences, individuals can significantly expand their understanding of DTF printing. Collaborating with others passionate about custom printing can lead to innovative ideas and valuable feedback, ultimately enhancing your skills and creativity in this exciting field.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct to Film transfers, are a modern printing technique that prints designs onto a specialized film instead of directly onto fabric. The process involves creating a digital design, printing it onto DTF film, applying adhesive powder, and then using heat to transfer the design onto fabric, resulting in durable and vibrant prints.

What are the benefits of DTF transfers for custom apparel printing?

The benefits of DTF transfers for custom apparel printing include exceptional color vibrancy, strong adhesion for long-lasting prints, and versatility across various fabric types. DTF can be used on materials like cotton, polyester, and nylon, making it an ideal choice for diverse custom apparel production.

How do I use DTF transfers effectively in my printing business?

To use DTF transfers effectively, start with high-resolution designs, choose quality DTF printers and heat presses, and perform test prints to ensure quality. Following best practices, like proper adhesive application and heat settings, will enhance your results in custom apparel printing.

What makes DTF printing stand out compared to other printing methods?

DTF printing stands out due to its ability to produce highly detailed, colorful designs on a wide range of fabrics while ensuring durability under washing and wear. This versatility and resilience make DTF transfers a preferred choice over traditional methods like screen printing.

What equipment do I need for the DTF printing process?

For the DTF printing process, you need a reliable DTF printer, a heat press, and specialized DTF film and adhesive powder. Investing in quality equipment is crucial for producing high-quality custom apparel with DTF transfers.

Are there any market trends that favor DTF Transfers in custom printing?

Yes, current market trends favor DTF transfers due to their efficiency and cost-effectiveness. As demand for customizable and durable apparel rises, DTF technology offers businesses a low barrier to entry, catering well to startups in the custom printing industry.

| Feature | Description |

|---|---|

| What are DTF Transfers? | DTF Transfers use a film printing process to apply designs onto fabrics, allowing for detailed and vibrant prints. |

| Advantages of DTF Transfers | 1. Versatility – Suitable for various fabrics. 2. Durability – Resists fading, peeling, and cracking. 3. Color Vibrancy – Produces bright and detailed images. |

| How DTF Transfers Work | 1. Design Creation 2. Film Printing 3. Adhesive Application 4. Heat Transfer |

| Best Practices | 1. Invest in quality equipment 2. Use high-resolution artwork 3. Conduct test prints before large runs |

| Market Trends | Growing demand for flexible and cost-effective printing solutions, especially for small startups in custom apparel. |

| Learning Resources | Online forums, YouTube tutorials, and blogs dedicated to textile printing provide valuable insights. |

Summary

DTF Transfers represent a cutting-edge advancement in custom apparel printing. This innovative technique stands out for its versatility, durability, and incredible color vibrancy, making it a preferred option for businesses and individuals alike. As the demand for high-quality, customizable apparel grows, DTF Transfers offer a wonderful solution to meet this need. Understanding the printing process, familiarizing yourself with best practices, and utilizing available resources will ensure that you can effectively navigate this exciting field of custom printing. Embrace the possibilities that DTF Transfers bring to your creative projects.