In the dynamic landscape of the fashion industry, DTF transfers are emerging as a game-changer in custom apparel printing. This innovative technology harnesses the power of Direct to Film printing, which enables vivid designs to be seamlessly applied onto garments, making personalized fashion more accessible than ever. With the rise of DTF printing advantages, small business apparel creators can now thrive, creating unique pieces that cater to individual tastes while significantly minimizing production costs. As the demand for customization grows, DTF transfers not only empower entrepreneurs but also redefine industry standards. Join us as we explore how this cutting-edge solution is reshaping the future of fashion design.

Revolutionary advancements in garment printing techniques are reshaping how designers approach custom clothing production. Direct-to-Film (DTF) technology, a pivotal player in this shift, facilitates the quick and efficient transfer of stunning designs directly onto various textiles, propelling personalized fashion to new heights. This contemporary method streamlines the printing process, offering small businesses the chance to showcase their creativity without the hefty investment traditionally required. As fashion enthusiasts increasingly seek unique and custom pieces, DTF solutions are proving essential for evolving market trends. Dive into the world of DTF printing and discover how it’s setting a new standard for the fashion industry.

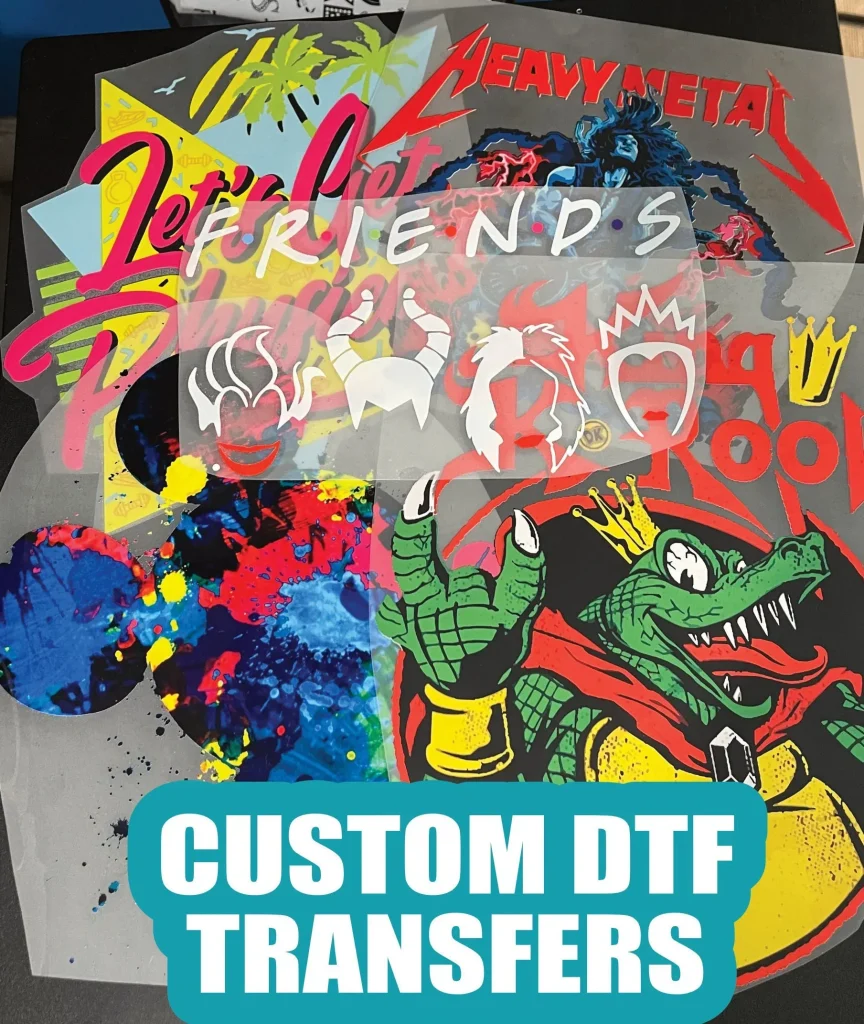

Revolutionizing Custom Apparel Printing with DTF Transfers

The fashion industry is undergoing a transformation, thanks to innovative printing techniques like DTF (Direct to Film) transfers. This method has revolutionized the realm of custom apparel printing by allowing designers and brands to bring intricate designs to life with unparalleled vibrancy. Unlike traditional methods, DTF printing ensures that colors remain brilliant and details are not lost, regardless of the fabric type. This capability makes DTF a go-to choice for those in the fashion landscape, promoting deeper engagement with clients and consumers.

Moreover, DTF transfers empower businesses, from large-scale manufacturers to small boutique operations. The technology fosters collaborative options within the custom apparel sector, providing opportunities for stylists and designers to showcase unique designs without the heavy investment in machinery. The significant reduction in time and material wastage allows for more experimentation, positioning DTF at the forefront of modern fashion technology.

Advantages of DTF Printing in the Fashion Industry

DTF printing presents multiple advantages over traditional printing methods, particularly in terms of speed and efficiency. One of the primary benefits is the ability to print vibrant images directly onto various textiles, ensuring that the output meets the demands of contemporary fashion trends. For businesses looking to produce small batches of custom apparel, the flexibility offered by DTF is unparalleled, eliminating the need for bulky setups and allowing for rapid design changes.

Additionally, DTF’s capacity to adhere to an array of materials opens the door for endless creativity. Designers can experiment freely with fabrics that were previously incompatible with other printing techniques, thus pushing the boundaries of what is possible in personalized fashion. This progressive edge strengthens the branding potential for emerging designers and small businesses seeking to carve their niche in the competitive market.

Empowering Small Businesses with DTF Technology

In today’s dynamic landscape, small businesses have a pivotal role in shaping the fashion industry, and DTF technology equips them with the tools necessary to thrive. With lower startup costs and simplified production processes, entrepreneurs can launch their custom apparel lines without incurring substantial debt. This democratization of fashion empowers creative individuals to pursue their entrepreneurial ambitions with confidence.

Furthermore, DTF’s low entry barrier enhances engagement among smaller brands, which can rapidly react to changing consumer preferences and fashion trends. This adaptability is crucial in a market that increasingly values uniqueness and personalization. Small businesses utilizing DTF technology are not just participants in the industry; they are driving forces that inject fresh ideas and innovations into the fashion landscape.

Case Study: Success Stories in DTF Transfers

One standout example of successful DTF implementation is Sam’s DTF Transfers, a company that illustrates how small businesses can leverage this technology to pave the way for market success. Founded to cater to both large and small clients, Sam’s DTF Transfers embodies reliability and quality in custom apparel production. Their focus on in-house DTF services has not only revolutionized local design capabilities but has also positioned them as a trusted partner for many designers.

Their journey reflects a broader trend in the fashion industry where innovative technology enables small entrepreneurs to access high-quality printing solutions that were once reserved for larger corporations. By proving that even the smallest of businesses can harness the power of DTF, Sam’s DTF Transfers serves as an inspiring case study for aspiring fashion entrepreneurs.

The Future of Personalized Fashion with DTF

As the fashion industry continues to evolve, the demand for personalized apparel is rapidly increasing. DTF technology plays a pivotal role in this trend by allowing for intricate customizations that cater to individual tastes and preferences. Consumers today are looking for garments that resonate with their identities, and DTF empowers brands to meet these demands with agility and precision.

Furthermore, advancements in DTF technology point towards a future where mass production and personalization can coexist harmoniously. This balance can lead to more sustainable fashion practices as brands can reduce overproduction by creating items that are specifically tailored to customer desires. There lies a significant opportunity for DTF printing to lead the industry toward a more conscious approach to fashion, prioritizing individualization without compromising quality or efficiency.

Sustainability in DTF Printing and Fashion

Sustainability is increasingly becoming a priority for consumers and brands alike. DTF printing offers advantages in this area by minimizing waste through efficient design reproduction. Since DTF technology allows for quick adjustments and limited runs of custom designs, it drastically reduces the risk of surplus production that often plagues the traditional fashion supply chain.

Moreover, as brands adopt eco-friendly practices, DTF technology provides an avenue for aligning with sustainable values. By adopting DTF transfers, fashion brands can not only cater to consumer demand for responsibly produced apparel but also contribute to a more sustainable future in the fashion industry. Emphasizing sustainability while offering high-quality and unique products will become crucial as the landscape of fashion continues to shift.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct to Film transfers, represent an innovative technique in custom apparel printing. In this process, designs are printed onto a special film and then transferred onto garments using heat. This method produces vibrant and intricate prints, making it suitable for various fabric types, and allows for greater design flexibility compared to traditional printing methods.

How do DTF transfers benefit small businesses in the fashion industry?

DTF transfers provide small businesses in the fashion industry with affordable access to high-quality printing without the need for extensive equipment. This technology reduces upfront costs and allows for small batch productions, enabling entrepreneurs to create personalized fashion lines quickly and efficiently, fostering creativity and market responsiveness.

What are the advantages of using DTF printing technology for custom apparel?

One of the primary advantages of DTF printing technology is its ability to produce vibrant, detailed designs. Unlike screen printing, DTF transfers allow for prints that are soft, durable, and flexible. This method also minimizes materials waste and offers fast turnaround times, making it increasingly popular among designers and print shops looking for effective solutions in custom apparel.

How are DTF transfers reshaping personalized fashion trends?

DTF transfers are significantly influencing personalized fashion trends by offering extensive customization options that cater to individual consumer preferences. As consumers seek unique clothing pieces that reflect their individuality, DTF technology facilitates rapid prototyping and adaptation of designs, thus meeting the demand for personalized fashion solutions.

Can DTF transfers be considered eco-friendly in the context of sustainable fashion?

Yes, DTF transfers align with sustainable fashion practices due to their efficient use of materials and lower production waste. As the fashion industry shifts towards more sustainable methodologies, DTF technology presents an eco-friendly alternative for custom apparel production, appealing to environmentally conscious consumers.

What role does Sam’s DTF Transfers play in the DTF printing landscape?

Sam’s DTF Transfers is a significant player in the DTF printing landscape, offering premium in-house DTF transfer services that cater to both large-scale printers and small business operators. Their commitment to quality and customer support enhances the accessibility of DTF technology, enabling a diverse range of clients to benefit from its innovative capabilities in custom apparel printing.

| Key Point | Description |

|---|---|

| Introduction to DTF Transfers | DTF transfers are changing custom printing in fashion, spotlighting personalization and innovation. |

| Mechanics of DTF Technology | A heat-based transfer method using printed film, adhesives, and specialized equipment to create detailed designs. |

| Adoption of DTF by Small Businesses | Increased accessibility for small businesses has led to a rise in custom apparel offerings. |

| Case Study: Sam’s DTF Transfers | Highlighting a successful company that supports both large and small scale printing needs. |

| Impact on Fashion Industry | DTF technology is revolutionizing how fashion is produced, enhancing creativity and reducing costs. |

| Sustainability Prospects | DTF aligns with sustainable practices, reducing waste and appealing to eco-conscious consumers. |

Summary

DTF Transfers are revolutionizing the fashion industry by providing a unique blend of customization and efficiency that has taken the market by storm. This innovative technology not only allows for vibrant and detailed designs but also empowers small businesses by lowering the barrier to entry in custom apparel production. As DTF continues to gain traction, it paves the way for more sustainable practices and personalized fashion experiences, catering to the evolving demands of consumers. Ultimately, DTF Transfers represent a significant shift, enabling a more inclusive and dynamic fashion ecosystem.