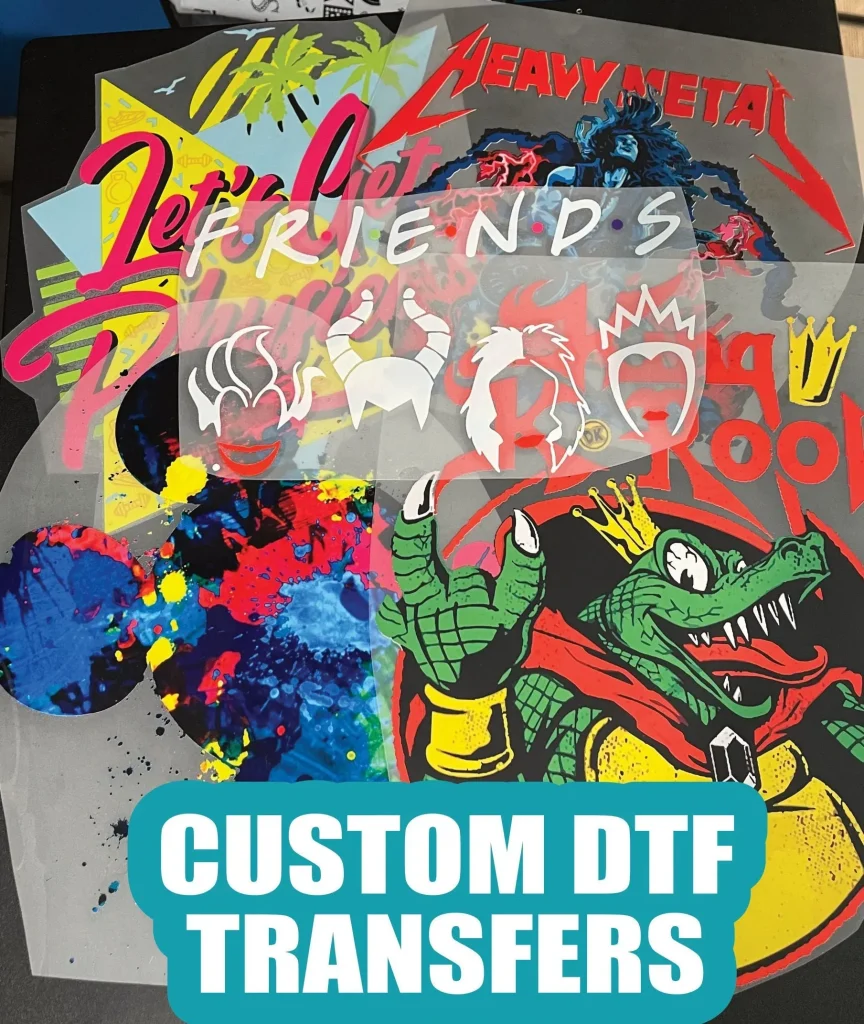

DTF Transfers, or Direct to Film transfers, are gaining traction in the realm of custom apparel printing, offering an innovative solution for those looking to create vibrant designs on fabrics. This cutting-edge technique combines the convenience of print on demand with the precision of heat transfer printing, making it an ideal choice for both hobbyists and professional printers. Through the DTF printing process, intricate graphics can be printed onto a specialized film and transferred with ease, resulting in high-quality results that can withstand the test of time. As the demand for personalized clothing continues to rise, understanding the advantages of DTF transfers becomes essential for anyone venturing into the world of garment decoration. This guide will explore the fundamentals and benefits of DTF transfers, providing you with all the information needed to successfully implement this exciting printing technology in your projects.

Exploring the concept of Direct to Film (DTF) printing reveals a robust method of creating designs that cater to the booming demand for custom fabric art. Also known as heat transfer printing, this innovative approach allows for detailed graphics to be printed directly onto a transfer medium before being applied to various textiles. Ideal for on-demand production, DTF transfers facilitate a seamless transition from digital design to wearable art, perfect for everyone from craft enthusiasts to small business owners. By leveraging the capabilities of this versatile printing technology, creators can offer unique, high-quality products that stand out in today’s competitive market. Whether you’re interested in merchandising or personal projects, embracing the DTF printing process can provide significant advantages in achieving stunning apparel designs.

Understanding the DTF Printing Process

The DTF printing process is a fascinating blend of technology and artistry that starts with creating a digital design tailored for custom apparel. This design is printed onto a special DTF film using a modified inkjet printer. This method ensures that the colors are vibrant and the details are sharp, making it suitable for complex, intricate graphics that are often seen in today’s fashion market. After the design is printed, a hot-melt adhesive powder is sprinkled onto the ink while it is still wet, allowing for a strong adhesive bond once cured. The preparation involves curing the adhesive with heat, which solidifies it and gets the print ready for application on fabric. This meticulous process guarantees that the colors remain bright and the print adheres well to various fabric types, enhancing the overall quality of the finished product.

In subsequent steps, the prepared DTF film is aligned onto the fabric and pressed with a heat press machine. This crucial step not only transfers the design but also ensures it is securely bonded to the fabric, resulting in a durable finish that can withstand daily use. This method contrasts with traditional heat transfer printing, which often requires pre-printed transfer sheets. DTF technology eliminates some of these steps, making it faster and more convenient for those entering the print-on-demand market. With the shift towards personalization in fashion and custom merchandise, understanding this process becomes vital for new entrepreneurs aiming to tap into the lucrative world of custom apparel printing.

Advantages of DTF Transfers in Custom Apparel Printing

DTF transfers bring a wealth of advantages, particularly in the realm of custom apparel printing. One of the notable benefits is their versatility. DTF technology allows prints to adhere seamlessly to a variety of fabrics such as cotton, polyester, and even blends. This adaptability means that whether you’re designing shirts, bags, or other items, DTF transfers can accommodate nearly any fabric choice, making it an excellent option for diverse merchandising needs. Additionally, the quality of DTF prints is exceptional; they produce vivid colors and detailed graphics that can really make your designs pop. For entrepreneurs, this opens the door to selling high-quality custom products that stand out in a crowded market.

Another significant advantage of DTF transfers is their durability. Unlike traditional printing methods which can fade or peel off after several washes, DTF prints are built to last. When properly cared for, these prints can endure regular wear and tear, retaining their original look long-term. This quality not only boosts customer satisfaction but also reduces the need for frequent reprints, making it a cost-effective solution. Moreover, the ease of use associated with DTF transfers simplifies the startup process for newcomers to the industry, enabling them to quickly learn and experiment with designs without being bogged down by complicated setup procedures.

Essential Equipment Required for DTF Transfers

To successfully navigate the world of DTF transfers, acquiring the right equipment is crucial. The backbone of this printing technique lies in the DTF printer, which is ideally a modified inkjet model designed specifically for printing on DTF film. This specialized printer ensures that the inks are suited for vibrant color reproduction and longevity on fabric. Coupled with a high-quality heat press, the setup facilitates smooth transfers of designs onto various substrates, which is essential for achieving polished and professional results. This investment in equipment might seem substantial at first but pays off as you grow your custom apparel business.

Additionally, users will need complementary supplies such as DTF film, adhesive powder, and transfer sheets. The films are coated to ensure optimum ink adherence while the adhesive used dictates the bond’s strength between the print and fabric. Selecting the right design software is also critical, as it helps users customize their artwork effectively while maintaining quality during the transfer process. By investing in reliable equipment and materials, entrepreneurs can streamline their production process and ultimately enhance the quality of their custom prints.

Cost Factors Involved in DTF Printing

When delving into DTF printing, understanding the cost implications is vital for any aspiring business owner. The initial setup for DTF transfers can be daunting, as the need for specialized printers and heat presses requires a significant financial investment. However, many entrepreneurs find that these upfront costs balance out over time due to the affordability of materials. While the initial expenses may appear high, the cost per print is relatively low, especially when producing smaller runs of custom apparel. This makes DTF printing an appealing option for those looking to enter the print-on-demand arena without incurring excessive overhead.

Moreover, the return on investment for DTF printing is promising. Since this method is suited for small batches and personalized items, you can cater to niche markets that traditional methods might overlook. The reduced waste and the ability to produce high-quality custom designs on demand translate into economic efficiency. By carefully tracking production costs and seeking out reliable suppliers for materials, you can ensure that your DTF printing venture remains profitable while also setting competitive prices for your custom apparel offerings.

Exploring the Latest Trends in DTF Printing

The DTF printing landscape is continuously evolving, with technological advancements driving new trends that enhance both quality and efficiency. One notable trend is the rise of eco-friendly inks and materials that resonate with the growing consumer demand for sustainable practices in printing. Companies are starting to prioritize environmentally conscious options, ensuring that their products not only look good but also align with customer values regarding sustainability. This shift presents new opportunities for brands to cater to eco-aware consumers while differentiating their offerings in a competitive market.

Additionally, the advancements in DTF printer technology are streamlining the printing process, making it more accessible for beginners. New machines are appearing with enhanced user interfaces and features that simplify the printing process. This accessibility is proving crucial for startups and hobbyists who want to explore the world of custom designs. With improvements in printing speeds and efficiency, even small home-based operations can confidently receive and fulfill customer orders in a timely manner, reinforcing DTF’s role as a leading process in the future of custom apparel printing.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct to Film printing, is a method where designs are printed onto a specialized film. This process involves printing the image, applying hot-melt adhesive powder, curing it, and finally transferring the design onto various fabrics using a heat press, making it a versatile option for custom apparel printing.

What are the advantages of using DTF transfers for custom apparel?

DTF transfers offer numerous advantages, including versatility across different fabric types, high durability against washing, and ease of use for beginners. This makes DTF a popular choice for custom apparel printing, enabling intricate designs to be applied effectively.

What equipment do I need to start DTF printing?

To begin with DTF transfers, you’ll need a specialized DTF printer, a quality heat press for transferring designs, and compatible design software. Essential supplies also include DTF film and hot-melt adhesive powder for successful execution of the DTF printing process.

Can DTF transfers be applied to various types of fabrics?

Yes, DTF transfers are highly versatile and can be applied to a wide range of fabrics such as cotton, polyester, and blends. This flexibility makes DTF the ideal choice for creating custom apparel, ranging from T-shirts to bags.

How does DTF printing compare to traditional heat transfer printing?

DTF printing differs from traditional heat transfer printing by allowing for better quality, faster production times, and the ability to print more intricate designs. The DTF printing process also ensures a stronger bond to the fabric, resulting in longer-lasting prints.

Is DTF printing cost-effective for small businesses?

DTF printing can be cost-effective, especially for small businesses or startups. Although the initial setup costs for equipment may be significant, the low material costs and minimal overhead for small runs make DTF transfers an efficient choice for custom apparel printing.

| Key Points | Details |

|---|---|

| 1. Process of DTF Transfer | Includes printing design, applying adhesive, curing adhesive, and transfer to fabric. |

| 2. Advantages of DTF Transfers | Versatile, durable, and easy to use for beginners. |

| 3. Necessary Equipment | DTF printer, heat press, design software, materials. |

| 4. Cost Considerations | Initial setup cost may be high, but materials are cost-effective over time. |

| 5. Potential Challenges | Learning curve for print settings and quality control is essential. |

| 6. Trends and Innovations | Emerging eco-friendly materials and advancements in printer technology. |

Summary

DTF transfers are revolutionizing the custom apparel landscape, offering accessible and efficient solutions for printing fabric designs. This innovative technique merges advanced technology with user-friendly processes, making it ideal for both beginners and seasoned creators. DTF transfers not only provide exceptional quality and durability but also cater to a variety of fabric types, ensuring versatility in project application. With a growing interest in eco-friendly practices and continuous innovations in equipment, DTF transfers are positioned to play a significant role in the future of personalized printing. Whether for individual hobby projects or small business ventures, embracing DTF transfers can truly enhance your creative endeavors.