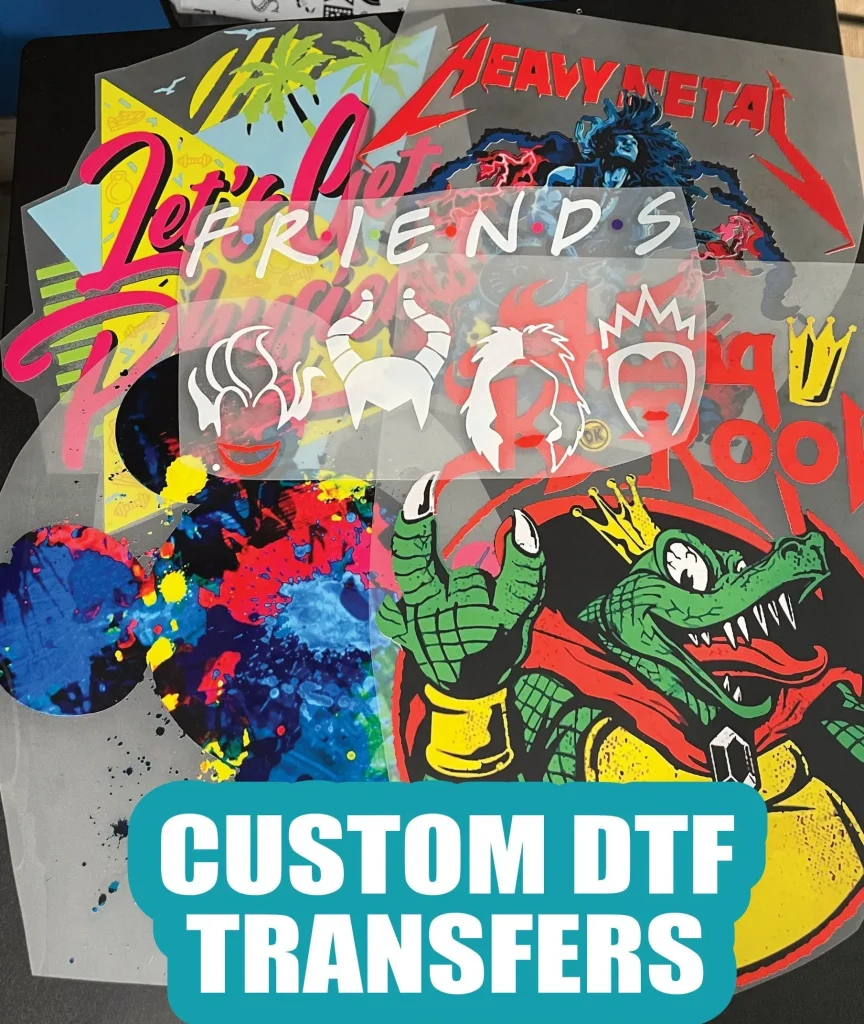

DTF transfers, or Direct-to-Film transfers, have emerged as a revolutionary technique in the world of garment decoration, combining the ease of digital design with the durability of traditional printing. This innovative method not only ensures vibrant and detailed prints on various fabrics but also streamlines the production process, making it a favorite among apparel decorators. With its unique DTF printing process, users can achieve stunning results that rival conventional methods like screen printing and vinyl application. In this article, you’ll discover valuable DTF transfer tips, covering everything from equipment choices to ideal heat press settings for flawless results. Join us as we delve into the exciting world of DTF transfers and elevate your garment decoration skills to new heights.

The world of Direct-to-Film printing, often referred to as DTF, is transforming the way custom designs are applied to textiles. This technique leverages advanced printing technology to create detailed, high-quality images that adhere seamlessly to garments. As professionals seek alternative methods for fabric printing, terms like film transfer and digital heat transfer are gaining popularity. These processes not only simplify the artwork application but also enhance the overall durability of prints, making them ideal for various fabric types. Understanding the nuances of DTF printing offers a brilliant gateway into contemporary garment decoration.

The Advantages of Direct-to-Film Printing

Direct-to-Film (DTF) printing offers numerous advantages that set it apart from traditional garment decoration methods. One of the most significant benefits is its versatility. DTF transfers can be applied to a wide range of fabric types, including cotton, polyester, and blends, allowing businesses to cater to various customer needs. This versatility enables print shops to expand their offerings without the limitation of fabric compatibility that often comes with other printing methods, such as screen printing.

Another key advantage of DTF printing is the quality of the prints it produces. With high-resolution images and vibrant colors, DTF transfers provide stunning visual results that capture attention. The process also ensures durability; DTF prints withstand multiple wash cycles without fading or peeling, making them ideal for apparel that sees regular use. This combination of quality and durability makes DTF printing an attractive option for both businesses and customers looking for long-lasting designs.

Essential Tips for Using DTF Transfers

To maximize the success of your DTF transfers, there are several tips that you should keep in mind. First and foremost, invest in high-quality DTF printers and supplies. Using reputable brands for both ink and film is crucial, as this can significantly impact the final product’s quality. Printers like Epson and Brother are known for their reliability and consistent output, ensuring that your designs turn out as expected.

Additionally, design plays a vital role in the effectiveness of DTF transfers. Designers should aim for high-resolution images to avoid pixelation and ensure clarity in the final print. Testing designs on sample fabrics before the final application helps identify any potential issues beforehand, such as color mismatch or adhesive problems. Such preparation can prevent costly mistakes and ensure a smoother transfer experience.

Understanding Heat Press Settings for DTF Transfers

Heat press settings are critical when using DTF transfers, as getting them right is essential for achieving the desired adhesion and longevity of the print. The general recommendation for most fabrics is to heat press at approximately 325°F (163°C) with a pressure setting between 40-60 psi. However, it is important to recognize that different materials may require slight adjustments to these settings to ensure optimal results.

For example, thinner fabrics may not need as much pressure, while thicker materials could require higher heat for adequate adhesion. Always conduct a test run on a small patch of fabric before performing a full transfer to avoid any mishaps that could result in damaged garments or poorly adhering prints. Understanding the specific needs of each fabric type will lead to better outcomes in your DTF printing endeavors.

Design Considerations for Successful DTF Transfers

Creating effective designs for DTF transfers means taking a few critical considerations into account. First, high-resolution images are essential to maintain quality throughout the transfer process. If a design is too intricate or detailed, it’s advisable to simplify it to ensure that the key visual elements come through clearly. Utilizing gradients and larger solid areas can be an excellent way to maximize visual impact without overcomplicating the transfer.

Moreover, color management is another crucial aspect of design for DTF transfers. It is essential to use the correct color profiles and conduct tests to ensure that the final printed colors align with what you envisioned. Even slight discrepancies in colors can lead to disappointing results. By being mindful of these design considerations, you can enhance the overall quality and appeal of your DTF printed garments.

Preparing Garments for DTF Transfer Application

Before applying DTF transfers, thorough preparation of the garment is vital to ensure a successful outcome. This process begins with pre-pressing the fabric to remove any moisture and wrinkles, creating an even surface for the transfer. Skipping this essential step can lead to uneven application and issues like misalignment or peeling after the transfer is complete.

Additionally, testing various fabric types with your DTF process can provide valuable insights into how each one reacts under heat and pressure. This preparation phase is crucial for identifying potential challenges and finetuning your approach for different materials, which will ultimately streamline your production and lead to better results.

Caring for DTF Transfers Post-Application

After successfully applying DTF transfers, proper post-application care is necessary to maintain the integrity and vibrance of the design. Allowing the garment to cure for at least 24 hours before its first wash helps strengthen the bond between the transfer and the fabric. This waiting period is crucial to avoid any premature wear that could compromise the design’s longevity.

When it comes time to wash the decorated apparel, it’s best to turn it inside out and select a gentle cycle. Washing in this manner minimizes the potential for wear and tear on the print, keeping it looking fresh and vibrant for numerous uses. Following these care instructions will extend the lifespan of your DTF transfers and ensure that customers continue to enjoy their beautifully decorated garments.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve a printing process where designs are printed onto a special film using a DTF printer. These printed films are then coated with a heat-activated adhesive powder. When pressed onto fabric with a heat press, the adhesive activates, transferring the design onto the garment. This method allows for vibrant, high-quality prints that adhere well to various types of fabrics.

What are some tips for successful DTF printing?

For successful DTF printing, it is essential to use high-resolution images to avoid pixelation. Additionally, maintaining correct heat press settings—around 325°F (163°C) with 40-60 psi pressure—is crucial for optimal adhesion. Make sure to pre-press the garment to eliminate moisture and wrinkles, and always test your transfers on different fabric types to understand their compatibility with the DTF process.

What are the recommended heat press settings for DTF transfers?

The recommended heat press settings for DTF transfers are typically 325°F (163°C) with a pressure range of 40-60 psi. It’s important to adjust these settings based on the specific fabric type being used, as different materials may require slight modifications for proper adhesion and to prevent damage to the garment.

How do I care for garments decorated with DTF transfers?

To care for garments with DTF transfers, allow at least 24 hours after application before washing. Wash inside out on a gentle cycle to protect the design, and avoid harsh detergents. Following these care instructions will help maintain the vibrancy and durability of your DTF transfers over multiple washes.

What types of fabrics work best for DTF transfers?

DTF transfers are versatile and can be applied to various types of fabrics, including cotton, polyester, and fabric blends. It’s important to test different fabric types before applying DTF designs to ensure compatibility and to achieve the best results.

What should I consider when designing for DTF transfers?

When designing for DTF transfers, focus on using high-resolution images to prevent loss of detail. Opt for simpler designs with fewer intricate details, as they are easier to transfer. Be mindful of color profiles to ensure accurate color reproduction. Incorporating gradients can enhance the design aesthetics while remaining suitable for the DTF printing process.

| Aspect | Details |

|---|---|

| Introduction | DTF transfers are revolutionizing apparel decoration with flexibility and quality. |

| Understanding DTF Transfers | They involve printing designs on a special film, which adheres to fabrics when heat pressed. Known for vibrant, durable prints across various fabrics. |

| Equipment and Materials | High-quality DTF printers, inks, films, and adhesive powders are vital for successful transfers. |

| Temperature and Pressure Settings | Optimal settings are around 325°F and 40-60 psi, adjusted for different fabrics. |

| Design Considerations | High-resolution images and simple designs enhance print quality. Color profiles must be accurately matched. |

| Pre-Press Preparation | Eliminate moisture and wrinkles by pre-pressing fabrics to ensure a smooth transfer process. |

| Post-Application Care | Allow 24 hours before washing and wash garments inside out on a gentle cycle to protect designs. |

Summary

DTF Transfers are transforming the apparel decoration landscape by providing an efficient and versatile method for applying intricate designs to various fabrics. By investing in quality equipment, optimizing heat press settings, and following proper pre- and post-application procedures, decorators can achieve durable and vibrant prints. The growing popularity of DTF technology signifies its importance in the customization market, allowing for endless creative possibilities that meet the demanding needs of modern consumers.