DTF transfers, or Direct-to-Film transfers, have transformed the landscape of small business custom prints and DIY printing. This innovative method allows creators to produce vibrant, high-quality designs on various fabrics with minimal effort and reduced costs. As the demand for cost-effective printing solutions grows, more entrepreneurs and hobbyists are turning to DTF printing for its ease of use and efficiency. Not only does this technique deliver impressive results, but it also supports sustainable printing practices by minimizing waste compared to traditional methods. With DTF transfers, the possibilities for customized apparel and promotional items are endless, making them an ideal choice for anyone looking to elevate their printing game.

Direct-to-Film printing, often referred to in the industry as film transfer technology, is becoming increasingly popular among DIY enthusiasts and small-scale manufacturers. This technique enables users to effortlessly create detailed and colorful prints, paving the way for unique custom merchandise. By utilizing film transfers, small businesses can achieve professional-quality results without the extensive setup associated with traditional screen printing methods. Furthermore, this approach not only streamlines the printing process but also aligns with contemporary sustainable practices, making it a smart choice for environmentally conscious creators. As the realm of custom prints expands, this innovative printing method stands out as a beacon of versatility and efficiency.

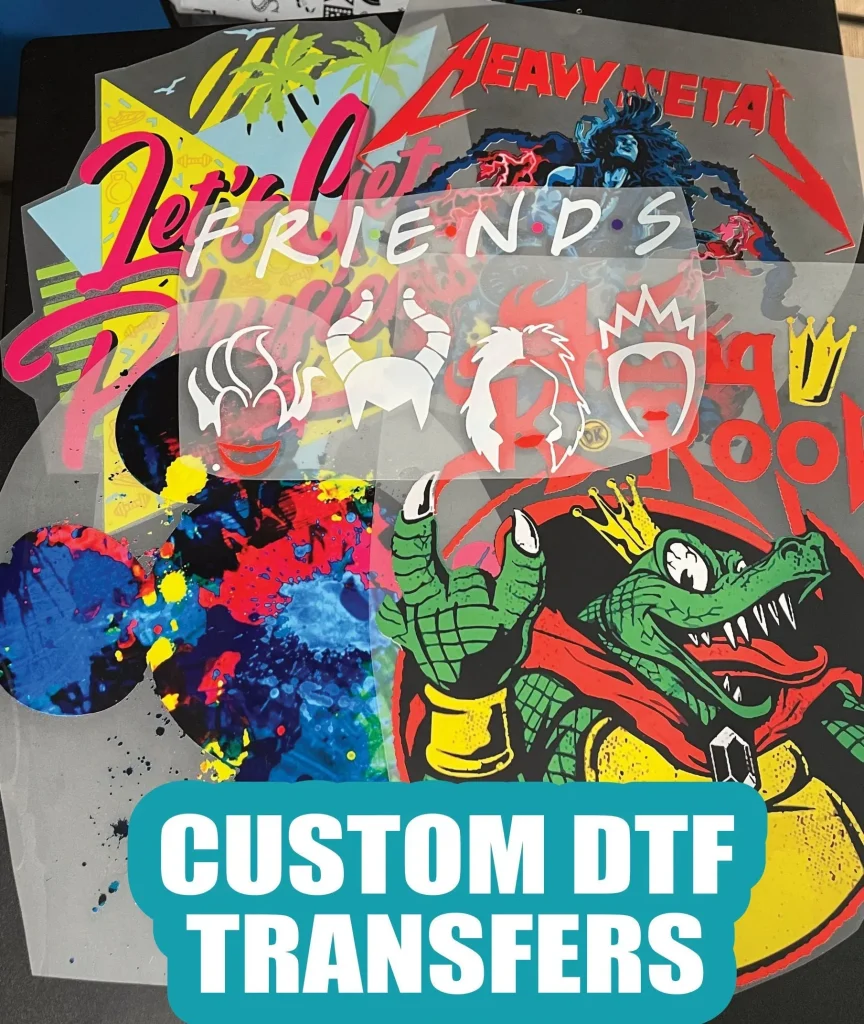

Understanding DTF Transfers: Revolutionizing DIY Printing

Direct-to-Film (DTF) transfers are indeed transforming the landscape of DIY printing and small business custom prints. At its core, this innovative method leverages a special film that allows for high-detail designs to be printed and then transferred onto various fabrics. The ability to print complex images with vibrant colors on fabrics such as cotton and polyester makes DTF not only versatile but also an ideal choice for anyone in need of high-quality results without the steep learning curve traditionally associated with printing techniques.

Moreover, DTF technology eliminates the hassle of preparing multiple screens, which is usually required in traditional screen printing. This simplification not only saves time but also significantly reduces production costs for DIY enthusiasts and small business owners. With DTF transfers, even those new to printing can produce professional-quality items that stand out in the competitive market of custom apparel.

The Advantages of DTF Printing for Small Businesses

For small businesses looking to make their mark, DTF printing offers unparalleled advantages. The cost-effectiveness of DTF transfers makes it possible for entrepreneurs to invest in quality custom printing solutions without breaking the bank. Compared to the expensive machinery needed for sublimation or traditional screen printing, a DTF printer is a more accessible option, making it easier for startups to launch their products and service offerings with minimal financial risk.

Additionally, the simplicity of the DTF process allows businesses to quickly adapt their offerings based on customer demand. Instead of being tied down to large bulk orders of a single design, small businesses can efficiently produce custom prints on-demand, catering to all customer preferences and enhancing overall consumer satisfaction.

Cost-Effective Solutions with DTF Transfers

One of the most compelling reasons to consider DTF printing is its cost-effectiveness. Entrepreneurs can capitalize on lower material costs associated with DTF transfers, especially when compared to traditional methods, allowing them to pass these savings onto their customers. This financial advantage opens the doors for a wider profit margin, which is particularly beneficial for small business owners navigating competitive markets.

Moreover, the ongoing advancements in DTF technology are continually reducing production costs. As this printing method becomes more mainstream, the affordability of essential materials and equipment is expected to decline, further enhancing its viability as a primary printing option for both hobbyists and entrepreneurs seeking sustainable and economical printing practices.

Sustainable Printing Practices with DTF

In a world where sustainability is increasingly important, DTF printing stands out for its environmentally-friendly approach. Traditional printing processes often generate a significant amount of waste through excess ink and the requirement for multiple screens. In contrast, DTF printing minimizes wastage with its efficient use of resources, making it a desirable option for creators who prioritize sustainable practices in their work.

Furthermore, utilizing DTF transfers aligns well with the growing consumer demand for eco-conscious products. By adopting sustainable printing practices, small businesses can position themselves as responsible contributors to the market, appealing to a demographic that favors brands committed to minimizing their ecological impact. This environmentally-friendly approach not only helps the planet but can also lead to enhanced loyalty and trust from customers.

The Rise of DTF Transfers in Custom Printing

The popularity of DTF transfers is rapidly on the rise, with more DIY enthusiasts and small businesses recognizing the myriad benefits it offers. This increased awareness has propelled DTF technology to the forefront of the custom printing industry, making it the go-to choice for those who seek efficiency without sacrificing quality. Industry forecasts suggest that this trend is not just a fleeting moment but a transformative shift that is here to stay.

As the custom printing market continues evolving, DTF transfers are likely to remain integral, thanks to their unique combination of ease, affordability, and versatility. With suppliers ramping up production and advancements in technology enhancing the printing capabilities, small businesses and individuals alike can confidently invest in DTF methods, knowing they are choosing a reliable and future-proof solution.

Getting Started with DTF Transfers for Your Projects

Starting with DTF transfers can seem daunting at first, but it’s simpler than many anticipate. The initial investment in a DTF printer can quickly pay off as users delve into creating unique custom prints that express their creativity. Many resources, including online tutorials and user forums, make acquiring the necessary skills accessible to everyone, ensuring that even beginners can navigate the process with ease.

Additionally, experimenting with DTF technology allows creators to offer personalized items that stand out in the market. This opens up opportunities for small businesses to diversify their product offerings, whether it is custom apparel, promotional items, or unique gifts. As individuals gain confidence in their printing skills, the potential for building a brand with DTF becomes increasingly evident, allowing for growth and expansion in the competitive world of DIY printing.

Frequently Asked Questions

What are DTF Transfers and how do they work for DIY printing?

DTF Transfers, or Direct-to-Film transfers, utilize a specialized film that captures high-quality images and prints them onto an adhesive layer. This process allows users to easily transfer vibrant designs onto various fabrics, including cotton and polyester, making it ideal for DIY printing projects. DTF printing is known for its versatility and straightforward application, helping DIY enthusiasts achieve professional-looking results.

How can small businesses benefit from using DTF transfers for custom prints?

Small businesses can significantly benefit from DTF transfers due to their cost-effectiveness and efficiency. The investment in DTF printing technology is lower compared to traditional screen printing setups, enabling startups to maintain low overhead costs. This allows for competitive pricing on custom prints while meeting customer demands quickly, making DTF an attractive option for custom apparel businesses.

Are DTF transfers a sustainable printing solution?

Yes, DTF transfers are considered a more sustainable printing solution compared to traditional methods. They generate less waste because they do not require multiple screens or excessive inks, thereby reducing material consumption. This aligns with the growing consumer demand for environmentally friendly practices, making DTF a suitable choice for brands focused on sustainable printing.

What types of materials are compatible with DTF printing techniques?

DTF printing techniques are compatible with a wide range of materials. Users can successfully print on cotton, polyester, and various fabric blends, making DTF transfers versatile for different custom apparel projects. This adaptability allows creators to explore various fabric options while ensuring vibrant and lasting prints.

How does DTF printing compare to traditional screen printing in terms of ease of use?

DTF printing is significantly easier to use than traditional screen printing methods. The process combines printing and application into fewer steps: print the design onto the DTF film, apply adhesive powder, and heat press it onto the fabric. This streamlined approach saves time and effort, making it ideal for those with limited experience in custom printing.

What makes DTF transfers a cost-effective choice for custom printing?

DTF transfers are a cost-effective choice because the initial investment in DTF printers and materials is lower than that of traditional sublimation or screen printing setups. Additionally, the efficiency of the DTF printing process reduces labor time and material waste, allowing small business owners and DIY enthusiasts to produce high-quality custom prints without incurring high costs.

| Key Points | Description |

|---|---|

| Introduction | DTF transfers offer a blend of flexibility, quality, and ease, appealing to DIY enthusiasts and small businesses. |

| What Are DTF Transfers? | DTF uses a specialized film to transfer detailed images onto fabrics without complicated setup procedures. |

| Quality and Versatility | Produces vibrant colors and maintains design integrity on various fabric blends. |

| Ease of Use | Simplifies the printing process into fewer steps, thus enhancing productivity for small businesses. |

| Cost-Effectiveness | Lower initial investment and affordable materials, making DTF ideal for startups and DIY enthusiasts. |

| Low Waste and Sustainability | Generates less waste compared to traditional printing methods, appealing to eco-conscious consumers. |

| Growing Popularity | The demand for DTF transfers is rising rapidly among creators and small businesses. |

Summary

DTF Transfers have emerged as a groundbreaking option for those looking to create custom designs efficiently and economically. These innovative transfers combine vibrant colors, ease of use, and sustainable practices, making them ideal for both DIY enthusiasts and small businesses. The simple application process allows anyone to produce high-quality items without needing extensive skills. As DTF technology gains traction, it not only meets the growing consumer demand for customization but also encourages environmentally responsible practices in printing. By adopting DTF transfers, individuals and entrepreneurs can enhance their creative endeavors while enjoying the benefits of a cost-effective and versatile printing method.