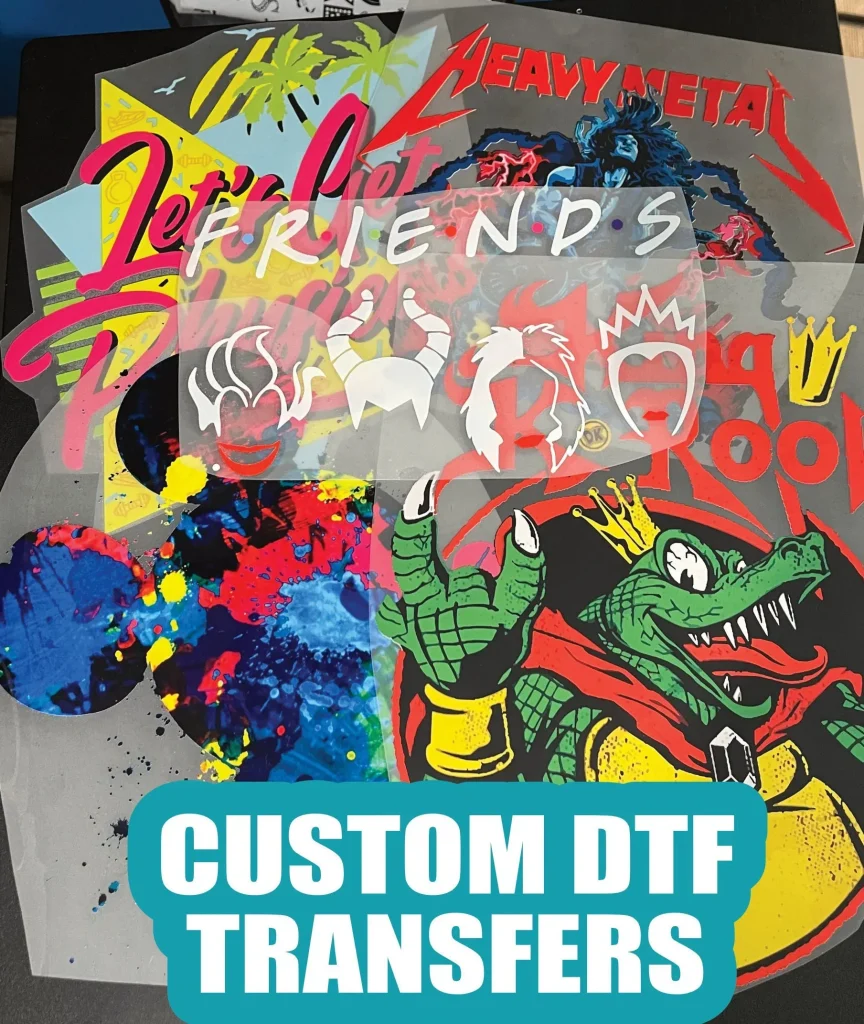

DTF Transfers, or Direct-to-Film transfers, are revolutionizing the custom apparel landscape, offering businesses new and efficient ways to meet consumer demands for personalized items. This innovative printing technique provides vibrant colors and exceptional durability, making it a top choice for entrepreneurs aiming to stand out in the crowded market. Not only does DTF printing offer unique benefits such as lower startup costs compared to traditional methods, but it also ensures high print quality that consumers are eager to embrace. By incorporating DTF Transfers into your business strategies, you can unlock new avenues for growth and maximize profitability in this burgeoning niche. Join the ranks of successful brands that have harnessed the potential of DTF printing to elevate their custom apparel offerings and delight customers.

Exploring the realm of Direct-to-Film printing can open doors to an exciting array of options in the realm of custom apparel and textile decoration. Often referred to as DTF, this advanced printing method utilizes specialized films to apply intricate designs onto various fabrics with remarkable precision and color vibrance. It’s a game-changing approach that empowers businesses to deliver high-quality printed products tailored to individual customer preferences without the high overhead costs associated with traditional printing methods. By understanding the nuances and advantages of this technology, entrepreneurs can effectively devise innovative business strategies to capture a share of the growing market for personalized apparel. As you navigate this engaging field, consider the advantages offered by DTF, including its cost-effectiveness and impressive print durability.

The Process Behind DTF Transfers

Direct-to-Film (DTF) transfers utilize a unique printing method that involves applying a design onto a special film. This film is treated with a hot melt adhesive that allows it to bond seamlessly with fabrics when heat is applied. The intricate process begins with high-resolution printing of graphics, which ensures that the colors are vibrant and the detail is sharp, making it an ideal choice for custom apparel. Once the print is complete, the film is then heated to set the adhesive, allowing for easy application onto t-shirts, hoodies, and other garments.

What sets the DTF process apart from traditional methods like Direct-to-Garment (DTG) printing is its flexibility in substrate compatibility. DTF transfers can be applied to a wider variety of materials, including cotton, polyester, and blends, making it a go-to option for businesses seeking diverse product offerings. Alongside this versatility, the environmentally friendly nature of DTF inks, which are often water-based, adds to its appeal in today’s eco-conscious market.

Exploring the Benefits of DTF Printing

DTF printing offers numerous benefits that empower businesses to optimize their production and profitability. One of the standout advantages is its cost-effectiveness; unlike screen printing, which requires extensive setup and multiple screens for color separation, DTF printing simplifies the process to a single print run. This leads to lowered initial costs, allowing startups to enter the custom apparel market without breaking the bank. Furthermore, the longevity of quality DTF inks ensures that each print withstands the test of time, maintaining its color vibrancy even after repeated washes.

Besides cost savings, DTF transfers provide remarkable efficiency. Businesses can quickly adjust designs without the need for extensive retooling, enabling them to respond promptly to customer requests and market trends. This speed is critical in attracting and retaining clients who prioritize rapid delivery alongside high-quality products. DTF’s adaptability also means that companies can easily explore seasonal designs or niche markets without the overhead associated with more traditional printing approaches.

Implementing Best Practices in DTF Transfer Production

To maximize success in DTF printing, businesses must implement best practices that ensure seamless operations and high-quality outputs. A core element is maintaining rigorous quality control throughout production. By investing in superior DTF inks and films, entrepreneurs can significantly enhance the durability and brilliance of their prints. Regular checks of equipment and procedures will help to identify potential issues before they affect product quality, allowing businesses to uphold customer satisfaction.

Beyond quality control, understanding and targeting specific market niches can lead to substantial profits. Researching trends within custom apparel, such as themes for events or popular culture references, allows companies to tailor their offerings effectively. Engaging directly with niche audiences through surveys or social media feedback can also guide design choices, ensuring products resonate with potential buyers.

Harnessing Innovative Marketing Strategies for DTF Products

Effective marketing is crucial in establishing a strong brand presence and driving sales in the DTF printing industry. Utilizing digital platforms like Instagram and Pinterest provides an invaluable opportunity to showcase visually appealing DTF designs. By curating striking imagery and engaging narratives around products, businesses can capture the attention of potential customers and encourage shares, fostering organic reach. Additionally, running targeted advertising campaigns can help to reach specific demographics, increasing visibility and customer acquisition.

Furthermore, participating in local craft fairs and online marketplaces can significantly enhance exposure. These venues not only allow for real-time customer interaction but also provide insights into consumer preferences. Engaging with customers face-to-face opens conversations that can yield valuable feedback and build lasting relationships, ultimately driving repeat business and word-of-mouth referrals. Incorporating educational content about DTF printing into marketing endeavors will also position businesses as knowledgeable leaders in the market.

Technological Advances in DTF Printing

The landscape of DTF printing is constantly evolving thanks to rapid technological advancements. Recent innovations have led to the introduction of faster and more efficient printing machines, capable of handling higher volumes and ensuring superb print quality. These technological improvements not only enhance productivity but also allow for creative flexibility, enabling businesses to experiment with intricate designs without compromising on speed or quality.

Additionally, the development of advanced inks that adhere better to various fabric types is revolutionizing the way businesses approach custom apparel. Staying abreast of these trends is essential for business owners looking to maintain a competitive edge. Investing in the latest technology not only streamlines production processes but also ensures that products meet the ever-growing consumer demands for quality and customization.

Real-Life Case Studies of DTF Transfer Success

Several businesses have successfully leveraged DTF transfers to revolutionize their operational models and boost profitability. For instance, a small enterprise specializing in custom merchandise found substantial growth after integrating DTF printing techniques into their workflow. They were able to produce a captivating range of apparel tailored to current trends, translating into increased sales and widespread brand recognition.

Such success stories underscore the adaptability of DTF printing during fluctuations in consumer preferences. By utilizing DTF technology, businesses can pivot quickly in response to market demands, bringing new and exciting products to life with minimal overhead. This agility not only attracts new customers but also enhances loyalty among existing ones, as they come to depend on the unique offerings that DTF printing enables.

Frequently Asked Questions

What are the main benefits of using DTF transfers for custom apparel?

DTF transfers provide several benefits for custom apparel, including cost-effectiveness, fast production times, and durability. This printing method utilizes affordable materials and ensures vibrant prints that withstand numerous washes, making it a favorite for entrepreneurs looking to deliver high-quality designs.

How does the print quality of DTF transfers compare to other printing methods?

DTF printing offers superior print quality when compared to traditional methods like Direct-to-Garment (DTG) and screen printing. It produces vibrant colors and sharp details, making it an excellent choice for complex designs on various fabrics.

Can DTF transfers be used on different types of fabrics?

Yes, DTF transfers are versatile and can be applied to a wide range of fabrics, including cotton, polyester, and blends. This flexibility allows businesses to cater to various customer preferences and expand their custom apparel offerings.

What budget should I expect for starting a DTF printing business?

Starting a DTF printing business can be more affordable compared to other printing methods. Essential equipment like a DTF printer, heat press, and quality inks can be obtained at a reasonable cost, making it an accessible option for entrepreneurs looking to break into the custom apparel market.

What effective marketing strategies can boost sales for DTF transfers?

To boost sales with DTF transfers, leverage social media platforms to showcase your designs, engage with your audience through tutorials, and explore partnerships with local events. Targeted advertising can also widen your reach and attract potential customers interested in custom apparel.

How can I ensure the durability of my DTF prints on apparel?

To ensure the durability of DTF prints, use high-quality inks and films during the printing process. Additionally, educate customers on proper care instructions, including washing in cold water and avoiding bleach, to maintain the longevity of the vibrant designs.

| Key Points | Description |

|---|---|

| Understanding DTF Transfers | DTF printing involves a specialized process where designs are printed on film and transferred to items with heat. It offers versatility, vibrant colors, and lower startup costs compared to DTG and screen printing. |

| Key Advantages of DTF Transfers | 1. Cost-Effectiveness: Affordable materials lead to higher profit margins. 2. Speed and Efficiency: Fast production meets customer demands. 3. Durability of Prints: Long-lasting prints enhance customer satisfaction. |

| Best Practices for Implementing DTF Transfers | 1. Quality Control: Ensure high-quality prints with quality materials. 2. Niche Targeting: Focus on specific audiences for better engagement. 3. Effective Marketing: Use social media and local events for exposure. 4. Customer Engagement: Build trust through consistent interaction. |

| Technological Advancements | Recent innovations in DTF technology enhance printing efficiency and customization capabilities, giving businesses a competitive edge. |

| Case Studies Demonstrating Success | Small businesses leveraging DTF printing have experienced growth, gaining success through unique, trend-driven apparel. |

Summary

DTF Transfers represent a significant opportunity for entrepreneurs to succeed in the custom printing market. By adopting high-quality materials, implementing efficient production processes, and leveraging strategic marketing efforts, businesses can thrive amidst competition. Engaging with niche audiences and utilizing innovative DTF technology can further enhance growth potential. As the market for personalized apparel continues to expand, DTF Transfers will play an integral role in shaping the future of custom design industries.