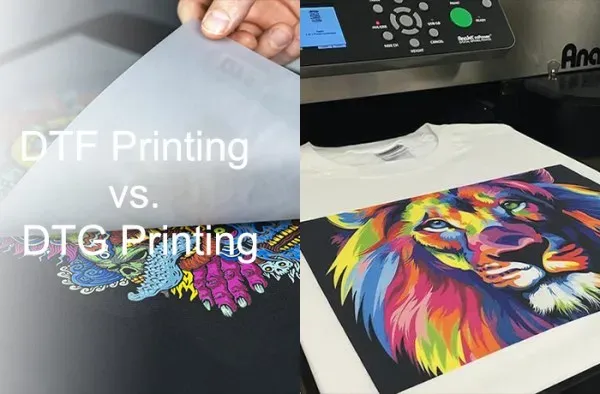

When it comes to fabric printing, understanding the nuances of *DTF vs. DTG printing* is essential for making informed decisions about your projects. Both *Direct to Film (DTF)* and *Direct to Garment (DTG)* printing methods offer unique advantages, making them popular choices in the textile industry. While DTG printing excels in producing intricate designs with vibrant color reproduction, DTF printing promises versatility across various fabric types and longer-lasting durability. This article compares DTF printing benefits with DTG printing advantages, providing a clear picture of how each method performs on crucial aspects like cost, speed, and quality. By delving into these fabric printing methods, readers can determine which technique best aligns with their garment printing goals and business needs.

In the realm of textile decoration, *Direct to Film (DTF)* and *Direct to Garment (DTG)* printing have emerged as two frontrunners among printing methods for garments. Understanding these terms is key for designers and businesses alike when selecting the best approach for their fabric printing needs. While DTF offers an innovative technique suited for a wide range of fabrics and durability requirements, DTG is celebrated for its ability to create detailed and colorful prints. This exploration not only highlights contrasting features but also invites a closer look at the methodology behind these popular fabric printing techniques. By effectively comparing DTF and DTG, those in the industry can make well-rounded decisions that cater to their unique project specifications.

Understanding the Basics of DTF and DTG Printing Methods

Direct to Garment (DTG) printing is a sophisticated process that applies ink directly to the fabric, allowing for intricate designs with vibrant color fidelity. This technology is particularly robust for creating detailed images, which makes it a preferred choice for fashion brands looking to produce unique apparel. However, the requirement for pre-treatment on the fabric can add to the time and costs involved, making DTG less feasible for quick turnover projects. As such, it’s essential for businesses to consider their specific needs, such as the desired quality and production timing.

On the other hand, Direct to Film (DTF) printing shifts the paradigm by printing designs onto a special film, which are then transferred to the fabric through heat. This method provides remarkable flexibility, allowing for printing on various fabric types from cotton to polyester. As a result, DTF has gained traction in the industry as a versatile solution that can cater to the needs of different market segments, particularly for those seeking durable prints that maintain their quality over numerous washes.

Quality Comparison: DTG vs. DTF Printing

When evaluating print quality, DTG takes the lead by delivering soft, vibrant prints with high levels of detail. This method shines particularly in small batch productions where high-quality images are crucial. Fashion-forward brands often opt for DTG printing due to its ability to achieve complex color gradients and fine details that resonate with customer demands for unique and personalized clothing. However, businesses should recognize that quality may diminish over time with extensive washing, potentially impacting customer satisfaction.

Conversely, DTF offers impressive quality as well, especially in durability and color steadfastness. The ability of DTF prints to withstand wear and tear while remaining visually appealing makes it an obvious choice for bulk orders where longevity is vital. While DTF may not achieve the same intricate detail as DTG for high-resolution designs, it compensates with its adaptability to different fabric types, providing a broad appeal to businesses looking for resilient printing methods.

Cost Efficiency: DTG versus DTF Printing Methods

Cost is often a decisive factor when choosing between DTG and DTF printing. DTG typically incurs higher upfront costs associated with more expensive machinery, specialty inks, and pre-treatment processes. While these expenses may outweigh the benefits for small quantities, they may be justified for businesses aiming to produce limited runs of high-end custom apparel with premium quality. Evaluating the target market will help determine if the investment is sustainable in the long run.

In contrast, DTF printing is generally more cost-effective, especially for larger orders. The absence of a pre-treatment phase and the ability to print on a variety of fabrics without incurring additional costs make DTF attractive for businesses focusing on bulk production. This lower cost coupled with faster setup times enables greater profit margins, especially for companies prioritizing efficiency alongside affordability. Balancing cost and quality will ultimately guide businesses to the most suitable printing method.

Production Speed: Choosing the Right Method for Fast Turnaround

Production speed is another critical aspect to consider in DTF vs. DTG printing. DTF usually outperforms DTG, particularly regarding large orders. Since DTF eliminates the pre-treatment step and streamlines the transfer process, businesses can complete bulk orders more efficiently. This faster production pace is influential in industries that demand quick fulfillment like promotional items or sports apparel, where turnaround time can significantly impact customer satisfaction and profitability.

DTG printing, while offering superior quality, often involves longer lead times due to its elaborate setup and pre-treatment needs. This process can hinder rapid production capabilities, especially for businesses with immediate delivery expectations. Therefore, if speed of fulfillment is a priority, opting for DTF could present a competitive advantage, allowing for the agile response that modern markets increasingly demand.

Market Trends: Shifts in User Preferences for Printing Solutions

Market trends indicate a growing preference for DTF printing among garment decorators. The versatility and resilience of DTF prints cater to a broader range of fabric types and customer needs, aligning with the current demand for durable and cost-effective production methods. Additionally, as businesses scale and aim for quicker turnaround times, DTF has emerged as a favorable alternative due to its efficiency and adaptability to large orders.

On the flip side, DTG remains highly regarded among small businesses and artisan producers who prioritize intricate designs and bespoke printing. The emphasis on quality over quantity resonates well in niches that seek elegance and uniqueness in their products. User preference between these two methods often leans towards the specific demands of their business model, market position, and customer expectations, showcasing the distinct roles each printing technique plays in the industry.

Evaluating Pros and Cons: Conclusion on DTF vs. DTG

In conclusion, both DTF and DTG printing methods hold unique pros and cons that cater to different business models. Companies looking for high-quality prints with intricate designs may find DTG to be the best fit, especially when their production volume aligns with the high setup costs. The method stands out for its exceptional print quality, appealing to brands focused on aesthetics and customer personalization.

Conversely, businesses that require cost-effective, versatile solutions with rapid production timelines should consider DTF printing. With its growing popularity, DTF excels in fulfilling bulk orders and adapting to various fabric types, allowing for extensive market reach. Evaluating the specific advantages and disadvantages of both printing methods will ultimately empower businesses to make informed decisions that align with their operational goals.

Frequently Asked Questions

What are the main differences between DTF vs. DTG printing?

The primary differences between DTF (Direct to Film) and DTG (Direct to Garment) printing lie in their processes and suitability. DTF prints on a special film, which is then transferred onto various fabric types using heat, making it versatile and durable for larger designs. Conversely, DTG directly applies ink onto garments, achieving excellent detail and vibrancy, but it’s primarily limited to cotton fabrics and requires pre-treatment, which can increase costs and production time.

What are the advantages of DTG printing compared to DTF printing?

DTG printing offers several advantages, including superior print quality and vibrant colors, ideal for intricate designs and small batch orders. The prints are soft to the touch, enhancing the garment’s feel. This method is perfect for custom apparel where detailed artwork is crucial, although it may incur higher initial expenses and requires pre-treatment.

What are the benefits of DTF printing over DTG printing?

The main benefits of DTF printing include its cost-effectiveness and versatility across different fabric types, including cotton, polyester, and blends. DTF proves to be more durable with high wash-resistance, making it suitable for sportswear or promotional items. Additionally, it typically offers faster production speeds, especially for larger orders, due to less setup time compared to DTG.

Which fabric printing method, DTF or DTG, is faster for production?

DTF printing is generally faster for production, particularly with larger orders. Unlike DTG, which requires pre-treatment of fabrics, DTF minimizes setup time, allowing for quicker turnarounds. This efficiency makes DTF a preferred choice for businesses needing to fulfill bulk orders promptly.

How do DTF printing benefits compare with DTG printing advantages?

DTF printing benefits include versatility for various fabric types, cost savings on setup, and improved durability. In contrast, DTG printing advantages focus on superior quality and the ability to produce intricate designs with a soft finish. Choosing between them involves evaluating your specific printing needs regarding quality, material, and production speed.

Can you summarize the DTF vs. DTG printing methods for garment design?

In summary, DTF and DTG printing methods cater to different garment design needs. DTG excels in detailed, high-quality prints ideal for smaller quantities, while DTF is suitable for larger runs, offering durability and versatility at lower costs. Your choice depends on factors like project requirements, fabric types, and budget considerations.

| Feature | DTF (Direct to Film) | DTG (Direct to Garment) |

|---|---|---|

| Quality of Print | Durable prints with vibrant colors, less intricate detail possible. | High-quality prints with superior softness and vibrant detail. |

| Cost Implications | Generally lower setup cost, no pre-treatment required. | Higher initial costs due to printer, pre-treatment, and inks. |

| Speed of Production | Faster production, especially for bulk orders. | Slower due to pre-treatment time. |

| User Preference | Preferred by large-scale production for versatility. | Favored by small businesses for quality and detail. |

Summary

DTF vs. DTG printing involves a comparison of two advanced fabric printing methods, each suited to different needs. DTF printing offers versatility, durability, and cost-effectiveness, making it ideal for large orders across varied materials. On the other hand, DTG printing excels in delivering high-quality, intricate designs suited for small batches on cotton fabrics. Your final choice should be influenced by the specifics of your project, such as the type of design, fabric, and production scale. Understanding these core differences ensures you select the best printing method for your requirements.