UV DTF transfer is changing how designers approach on-demand printing, delivering vibrant results on a wide range of substrates. When you compare DTF vs sublimation and the DTF transfer vs heat transfer approach, UV DTF transfer often offers easier multi-color capability and a cleaner workflow. Its UV-curable inks provide solid color, quick curing, and compatibility with cotton blends, expanding options beyond traditional sublimation. For those weighing approaches, understanding how UV printing durability stacks up on different fabrics is essential. It also helps illuminate how this method compares to sublimation printing on fabric when selecting the right technique for each product.

Within the broader UV-led transfer family, you’ll see phrases like UV-direct-to-film printing and film-based ink transfer that describe the same process from a slightly different angle. This framing aligns with LSI principles by linking related ideas such as direct-to-film techniques, UV-curable ink systems, and multi-substrate versatility. In practice, readers will encounter terms like white-ink on film, heat-press bonding, and durability goals that echo the core benefits of the technology. By presenting these alternative terms, we map the landscape from ‘UV DTF transfer’ to closely related concepts, helping you make a more informed production decision.

UV DTF Transfer: Substrate Versatility and White Ink Capabilities

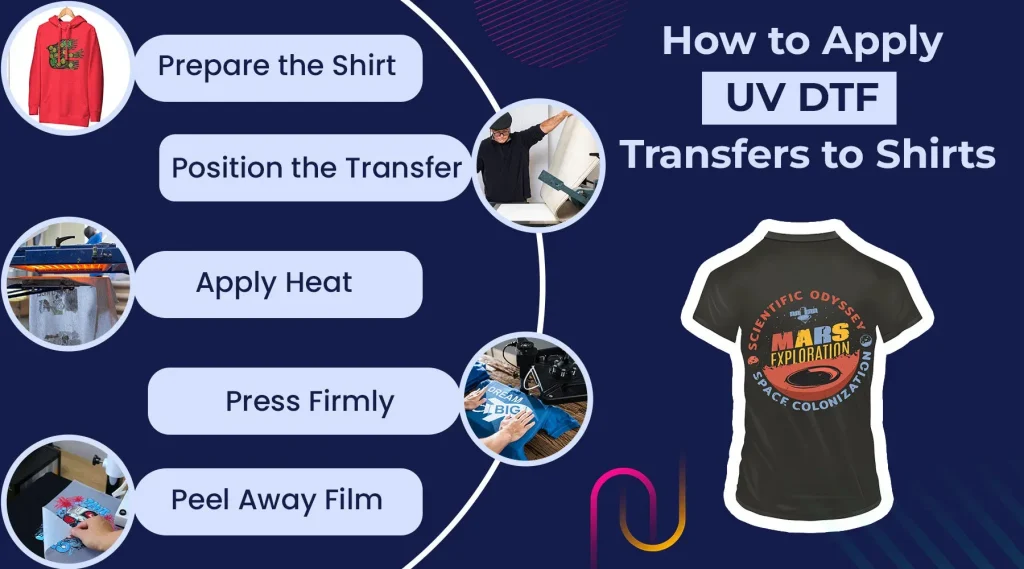

UV DTF transfer uses a film printed with UV-curable inks, a bonding powder, and a curing step before transfer to the final surface. This workflow supports a wide range of substrates, from cotton blends to mugs and even certain plastics, giving you a flexible platform for on-demand production and test designs.

A key advantage is white ink opacity on dark fabrics, enabling vibrant designs without the base color of the garment overpowering the print. Because UV inks cure quickly and bond well with various adhesives, you can achieve solid color blocks and detailed artwork with reliable durability when paired with proper heat, dwell time, and post-processing.

DTF Transfer vs Heat Transfer: Core Process and Performance Trade-Offs

DTF transfer (the film-based Direct-to-Film process) and traditional heat transfer differ in steps, materials, and resulting hand feel. DTF uses a film printed with UV-curable inks, a bonding powder, and a curing phase before transfer. In contrast, heat transfer typically relies on a printed sheet or vinyl that is pressed onto a substrate with heat, often without a curing stage.

In terms of durability and washability, DTF can offer solid performance on cotton blends and some poly blends, while heat transfers can vary with thickness and adhesive quality. If you’re weighing DTF transfer vs heat transfer, consider substrate compatibility, required durability, and how the final product will be handled in regular wear.

UV Printing Durability: Long-Term Color Stability Across Substrates

UV printing durability hinges on ink chemistry and substrate compatibility. UV DTF transfers use UV-curable inks that resist fading and maintain color when exposed to light and washing conditions. On non-porous or mixed substrates, the cured layer remains relatively stable when proper curing and adhesion are achieved.

To maximize longevity, calibrate color profiles for each substrate and follow recommended heat and washing guidelines. Consistent maintenance and post-processing play a big role in ensuring the print remains vibrant over time, especially for cotton blends or items with frequent abrasion.

Sublimation Printing on Fabric: Color Brightness on Polyester and Coatings

Sublimation printing on fabric yields deep, saturated colors because the dye becomes part of the substrate on polyester-based textiles or polymer-coated surfaces. The color transfer is embedded at the molecular level, leading to excellent color fastness and minimal cracking over time.

Note that sublimation excels on polyester and coated hard goods, but natural fibers like 100% cotton require special coatings or blending to approach similar results. Substrate preparation and coatings directly impact color rendition, durability, and the overall feel of the finished product.

DTF vs Sublimation: Choosing the Right Method for Your Product Mix

A practical decision often starts with mapping your best-selling substrates and product categories. If your catalog blends cotton-rich garments, mugs, and irregular shapes, DTF transfer may offer flexibility; if most items are polyester apparel or coated hard goods, sublimation becomes the logical strategy. This is where DTF vs sublimation guidance helps prioritize the right method for each item.

Implement a pilot program to compare cost per unit, color accuracy, and durability across your top products. Use a color-managed workflow with ICC profiles, test wash scenarios, and gather customer feedback. If your catalog demands versatility, you can pursue a hybrid approach that uses UV DTF transfer for cotton and mixed-media items while reserving sublimation for high-volume polyester lines.

Hybrid Strategies: Building a Dual-Method Studio for Diverse Catalogs

A dual-method studio leverages the strengths of UV DTF transfer and sublimation to cover wide substrate ranges and product types. In practice, you might print cotton-friendly designs with UV DTF and reserve sublimation for polyester garments and polymer-coated goods, yielding strong color and durability across items.

To maintain efficiency, integrate color management, standardized post-processing, and shared tooling where possible. This hybrid approach reduces risk of stockouts for diverse catalogs and supports on-demand printing with optimized turnaround times.

Frequently Asked Questions

What is UV DTF transfer and how does it compare to sublimation?

UV DTF transfer uses UV-curable inks printed onto a film, followed by bonding powder, curing, and transferring the design with heat. It offers broad substrate compatibility and can print white ink on dark fabrics, while sublimation embeds color into polyester and coated surfaces for high color vibrancy. In short, UV DTF transfer is versatile for cotton blends and unusual substrates, whereas sublimation excels on polyester with different setup requirements and costs depending on volume.

How durable is UV printing when using UV DTF transfer on different substrates?

Durability depends on film quality, bonding agents, and how well the garment is heat-cured. UV DTF transfers typically resist washing well on cotton blends and similar fabrics when properly applied, but substrate texture and care instructions can affect long-term performance. For best results, validate adhesion and follow recommended heat dwell times for each substrate.

Can sublimation printing on fabric be used on cotton or blends, and how does that compare to UV DTF transfer?

Sublimation works best on polyester fabrics and certain coated blends; cotton or natural fibers usually require coatings or aren’t suitable without special preparation. UV DTF transfer handles cotton blends more reliably and provides white ink opacity on dark fabrics. For cotton-heavy catalogs, UV DTF is often the practical choice; for pure polyester, sublimation typically offers superior color saturation.

DTF transfer vs heat transfer: what’s the difference?

DTF transfer is a film-based process that uses a binding adhesive and a heat press to bond ink to the fabric, delivering durable prints with a soft hand. Heat transfer is a broader category that includes vinyl and other adhesive-based methods, which can feel heavier and may crack or peel over time. Generally, DTF transfer offers better durability and stretch with proper setup.

Which method is better for a mixed product catalog: UV DTF transfer or sublimation?

If your catalog includes cotton blends, mugs, or unusual shapes, UV DTF transfer provides versatility with white ink opacity on dark fabrics. If most products are polyester or sublimation-coated items, sublimation is often more efficient for large batches and color consistency. Many shops succeed with a hybrid approach: UV DTF for cotton-heavy items and sublimation for polyester-based products.

How does white ink opacity in UV DTF transfer affect print visibility on dark fabrics and what about UV printing durability?

White ink opacity on the transfer film enables clear, bright designs on dark garments, improving visibility and color accuracy. With proper curing and high-quality materials, UV printing durability remains strong across common fabrics, but care instructions and substrate type still influence longevity. Always test on your specific substrates to optimize performance.

| Aspect | UV DTF Transfer | Sublimation | Notes / Takeaway |

|---|---|---|---|

| Substrates compatibility | Broad range: cotton blends, some polyesters, mugs, coated surfaces | Optimized for polyester fabrics and polymer-coated items; not ideal for 100% cotton unless treated | UV DTF is versatile for mixed fabrics; sublimation excels on polyester and coated items. |

| Color and vibrancy | Strong color with white ink support; good opacity on dark fabrics depending on layer | Vivid, full-color results on appropriate substrates; gradients and blends well-supported on polyester | White ink can enhance opacity on dark fabrics; sublimation requires suitable substrate for best color. |

| Durability and washability | Good resistance with proper heat/dwell time; strong on cotton blends | Excellent durability on polyester; color embedded in substrate | Durability depends on substrate; sublimation often outperforms on polyester for long-term colorfastness. |

| Feel / Hand | May feel raised due to adhesive layer/film thickness | Often very smooth/soft; print embedded in polymer coating on fabrics | Hand varies with substrate; consider substrate texture and ink thickness. |

| White ink / opacity | White ink layers common; strong opacity on dark fabrics | White isn’t inherent; relies on substrate or white underbase for dark fabrics | Plan white opacity needs; test on chosen substrates. |

| Setup & costs | Printer capable of UV inks or a standard printer with UV-curable inks; bonding powder and heat press | Sublimation printer, heat press, sublimation inks, and compatible substrates | Total investment varies with volume; UV DTF may be cheaper for mixed substrates; sublimation favorable for high-volume polyester runs. |

| Workflow & speed | Print onto film, apply bonding powder, cure, then transfer; good for small batches | Heat transfer to substrate; efficient for large runs but setup changes can add time | Choose based on batch size and substrate variety; pilot runs recommended. |

| Best use cases | Cotton-rich fabrics, mixed substrates, mugs and irregular shapes | Polyester fabrics and polymer-coated items; high-volume color durability | Hybrid approaches often optimal: UV DTF for cotton/mixed items; sublimation for polyester and coated goods. |

| Maintenance & QC | Keep printers clean, calibrate, use ICC profiles, test inks | Color management, substrate testing, machine maintenance | Ongoing testing and color control are essential for consistency across substrates. |

Summary

UV DTF transfer and sublimation are not strictly competing technologies but rather complementary tools in modern print workflows. UV DTF transfer offers broad substrate versatility, strong white ink opacity on dark fabrics, and flexibility for cotton-rich garments and unusual materials, making it a solid all-around option for mixed catalogs and on-demand production. Sublimation delivers vibrant, durable color embedded in polyester and coated surfaces, with high efficiency for large-volume runs. For many businesses, a hybrid approach—using UV DTF transfer for cotton blends, unusual substrates, and mixed-media items, alongside sublimation for polyester apparel and coated hard goods—often yields the best balance of quality, efficiency, and cost. To succeed, invest in careful testing, color management, and consistent quality control, ensuring reliable results across orders and substrates.