The **DTF printing process**, or Direct to Film printing, is gaining popularity as an innovative method for custom apparel printing that combines high efficiency with exceptional quality. It allows designers to create vibrant and intricate designs that can be transferred onto various types of fabrics, making it a versatile choice for both small businesses and larger manufacturers. As technology advances, tools like the Epson DTF printer have emerged, providing enhanced printing capabilities that cater to diverse artistic visions in high-quality fabric printing. This process is not only cost-effective but also enables creators to enjoy numerous DTF printing benefits, such as long-lasting prints that withstand the test of time. In this article, we will explore the DTF printing process in detail, highlighting its mechanics and advantages in the ever-evolving apparel industry.

The Direct to Film (DTF) printing technique is a cutting-edge approach that redefines fabric printing by allowing creative designs to be printed on special films before being transferred onto textiles. Often hailed as a game-changer in custom garment production, this method utilizes advanced technology for producing high-quality images that adhere effectively to various materials. Thanks to innovations from leading manufacturers, the DTF printing process integrates seamlessly into modern apparel production, catering to both bespoke and mass-market needs. By understanding this dynamic printing technique, businesses can leverage its unique advantages to enhance their offerings in the competitive world of fashion and custom apparel.

Understanding the Basics of DTF Printing

The DTF printing process, or Direct to Film printing, represents a significant innovation in the field of custom apparel printing. By utilizing a specialized film that captures vibrant colors, this method stands out from traditional printing techniques. Artists and businesses can create intricate designs that boast durability and high-quality finishes. The technology allows for seamless integration of various fabric types, making it a highly versatile solution for personalized fashion.

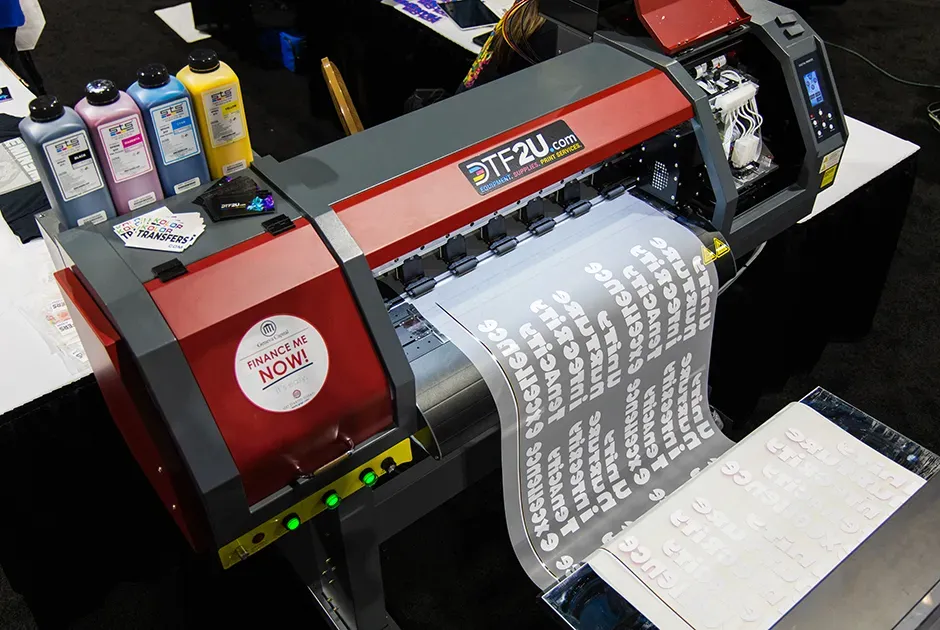

In the realm of custom apparel, DTF printing has gained popularity due to its performance and efficiency. The ability to print directly onto a film means designs are not hindered by the fabric’s texture, allowing for more detailed and varied output. Furthermore, with advancements in machines like the Epson DTF printer, the process has become more accessible to small businesses, giving them the tools to produce professional-grade prints without heavy investment.

The Step-by-Step DTF Printing Process

To fully appreciate the capabilities of DTF printing, it helps to understand the step-by-step process that goes into creating these remarkable prints. Starting with design preparation, artists craft digital artwork that is meticulously formatted for high-resolution outputs. This preparation ensures that when transferred to the film, the colors remain true and vivid—critical for achieving stunning visual results.

Next, the DTF printing process shifts into action as water-based inks are applied to the film, leveraging the advanced technology of printers like the Epson DTF model. This step is crucial for preserving the integrity of vibrant colors after the heat transfer. Once the ink has been applied, a powdered adhesive is sprinkled, readying the design for adhesion to fabrics in the subsequent heat press stage.

Technological Innovations in DTF Printing

Recent innovations in DTF technology have transformed the landscape of custom apparel manufacturing. With the introduction of the Epson SureColor G6070, manufacturers can produce wider prints with even greater detail and vibrancy. This represents a major leap forward in production capabilities, allowing businesses to meet the growing demand for custom designs in larger quantities without compromising quality.

Companies are also refining their processes to accommodate diverse fabrics and complex designs with the latest advancements. For instance, AM.CO.ZA’s compact A3 DTF printer is specifically engineered to cater to small businesses, enabling them to engage in the print-on-demand market. Such innovations ensure that DTF printing isn’t just about high-quality output but also about accessibility for all creators in the apparel space.

Benefits of Using DTF Printing for Apparel

DTF printing boasts numerous benefits that appeal to business owners and apparel designers alike. One of the most significant advantages is the ability to produce high-quality, durable prints that resist fading. This quality allows apparel to maintain its vibrant designs even after repeated washing, ensuring long-term customer satisfaction and retention.

Additionally, DTF printing is cost-effective, as it accommodates both small and large production runs. This flexibility makes it an attractive option for startups looking to test the waters of custom products without committing to extensive inventory upfront. Furthermore, the user-friendly nature of DTF printing machines allows anyone to dive into the world of custom apparel creation with relatively little training.

Versatile Applications of DTF Printing

One of the standout characteristics of DTF printing is its versatility in terms of application across a wide range of fabrics. Whether it’s cotton, polyester, or blends, DTF printing effectively transfers intricate designs onto diverse materials, making it ideal for various apparel types, including t-shirts, hoodies, and sportswear. As such, businesses can cater their offerings to numerous markets, attracting a broad customer base.

Moreover, the adaptability of DTF printing extends beyond textiles, opening doors for creative ventures like custom home decor and promotional products. Designers can experiment with different fabric textures and weights, pushing the boundaries of creativity while providing customers with unique and personalized items that stand out in a crowded marketplace.

Future Trends in DTF Printing

The future of DTF printing looks promising as the technology continues to evolve. With advancements such as improved ink formulations and more efficient printing equipment, the customization possibilities are expanding. Businesses are now able to fulfill increasing consumer demands for personalization and unique offerings, making DTF printing a pivotal player in the apparel industry.

Furthermore, sustainability plays a growing role in modern printing techniques, and DTF printing is no exception. Innovations aimed at reducing waste and using eco-friendly materials are on the rise, with manufacturers exploring options that lessen their environmental impact while still delivering high-quality, vibrant prints. As these trends gain traction, we can expect DTF printing to not only enhance design capabilities but also align with the principles of sustainability that consumers increasingly demand.

Frequently Asked Questions

What is the DTF printing process and how does it work?

The DTF printing process, or Direct to Film printing, involves printing designs onto a special film that is then heat pressed onto fabric. This method ensures vibrant and high-quality fabric printing, making it ideal for custom apparel.

What are the benefits of using DTF printing for custom apparel?

The benefits of DTF printing include high-quality prints that resist fading, versatility across various fabric types, cost-effectiveness for small and large runs, ease of use for beginners, and limitless customization options, enhancing its appeal for custom apparel businesses.

How does the Epson DTF printer enhance the DTF printing process?

The Epson DTF printer, like the SureColor G6070, improves the DTF printing process by offering wider print capabilities and advanced production features, which enhances the quality of designs and increases efficiency in high-volume custom apparel printing.

Can DTF printing be used on all types of fabrics?

Yes, DTF printing is versatile and can be used on a wide range of materials, including cotton, polyester, and blends, making it an excellent choice for creating diverse custom apparel.

What is the step-by-step process of Direct to Film printing?

The DTF printing process involves several key steps: design preparation, printing on film, application of a powder adhesive, curing the adhesive, heat pressing onto fabric, and finally, removing the film to reveal the vibrant design on the garment.

How does DTF printing compare to other custom apparel printing methods?

DTF printing offers several advantages over other methods, including superior color vibrancy, durability of prints, adaptability to various fabrics, and a user-friendly approach for both beginners and professionals, making it a preferred choice in the custom apparel printing market.

| Key Point | Description |

|---|---|

| What is DTF Printing? | A versatile printing method where designs are printed on film and transferred to fabric using heat, offering high-quality, vibrant prints. |

| Steps of the DTF Process | 1. Design Preparation: Create digital artwork with graphic software. 2. Printing on Film: Use specialized film and water-based ink. 3. Powder Adhesive Application: Sprinkle adhesive on printed film. 4. Curing the Adhesive: Heat press to bond ink with adhesive. 5. Heat Pressing onto Fabric: Apply coated film to fabric with heat. 6. Removing the Film: Carefully peel off the film for a final printed garment. |

| Benefits of DTF Printing | – High-quality prints – Versatile for various fabrics – Cost-effective for small and large runs – User-friendly equipment – Unlimited customization options |

| Technological Advancements | Recent innovations, such as Epson’s SureColor G6070, improve production capabilities, making DTF printing more accessible for all business sizes. |

Summary

The DTF printing process is an innovative method that transforms artwork into high-quality printed apparel. This versatile technique allows for intricate designs to be printed directly onto a film, which is then easily transferred onto various fabrics using heat. As technology evolves, DTF printing is becoming increasingly accessible, enabling both small businesses and hobbyists to produce stunning, durable products. The benefits of DTF printing extend beyond simply creating appealing designs; they also include cost-effectiveness and adaptability across different fabric types. With ongoing advancements in printing technology, the potential for DTF printing continues to grow, opening up exciting possibilities for creative expression in the apparel industry.