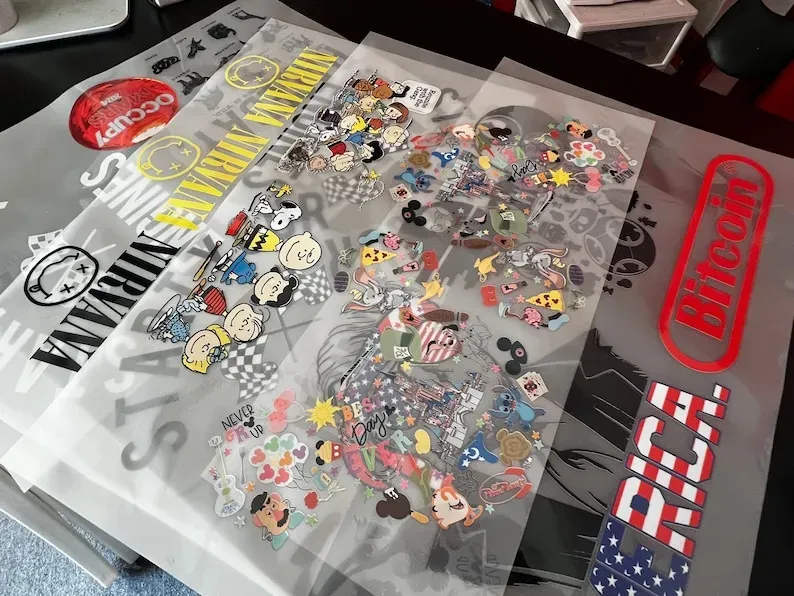

In the dynamic landscape of Direct-to-Film (DTF) printing, the DTF gangsheet stands out as a revolutionary tool for optimizing print operations. This innovative method not only enhances efficiency but also significantly minimizes waste, making it a favorite among entrepreneurs and print professionals. A well-constructed gangsheet allows for multiple designs to be printed simultaneously, streamlining the DTF printing process and reducing production costs. As you delve into this guide, you will discover the secrets to building the perfect DTF gangsheet, turning your creative visions into reality while maintaining high-quality outputs. Prepare to elevate your print game and unlock new levels of productivity with expert insights into design, materials, and techniques.

Exploring alternative terms, the gangsheet concept in DTF printing encompasses various methods that facilitate bulk production of designs on a single film sheet. Often referred to as multi-design layouts or print sheets, these techniques are essential for both small-scale operations and larger print providers. By employing such efficient strategies, print businesses can not only fulfill customer demands swiftly, but also enhance their overall operational workflow. Whether you call it a ganging sheet, a print sheet, or a multi-design transfer, mastering these methods will profoundly impact your quality and efficiency in the print industry. Understanding the intricacies of the DTF printing process and leveraging these synonyms will enable you to optimize your print shop’s capabilities and respond adeptly to market needs.

Understanding the Basics of DTF Printing

Direct-to-Film (DTF) printing is a modern and highly efficient method that allows users to print designs directly onto a special film before transferring them to fabric. This technique has transformed the printing landscape by enabling high-quality, vibrant prints on a variety of materials. Unlike traditional printing methods, DTF printing employs a unique process where the ink is first printed onto film and then cured with an adhesive powder, which is crucial for ensuring that the final product is durable and long-lasting.

The DTF printing process is particularly appealing for small businesses and designers looking to produce custom apparel or merchandise on demand. Because DTF gang sheets can incorporate multiple designs within a single print run, businesses can save time and resources while producing high-quality products. This efficiency not only benefits the bottom line but also aligns with sustainable practices by minimizing waste, further solidifying DTF printing as a leading choice in the print industry.

The Importance of DTF Gang Sheets in Production

DTF gang sheets are a game changer for print shops and designers, enabling them to maximize their resources and optimize production workflows. By consolidating multiple designs into a single gang sheet, printers can significantly reduce the amount of film and adhesive powder used. This practice not only cuts costs but also minimizes the ecological footprint associated with printing processes.

The strategic arrangement of designs on a gang sheet also plays a crucial role in print efficiency. By ensuring that designs are spaced correctly, printers can enhance the clarity and quality of each print. The gang sheet method encourages a streamlined workflow, allowing operators to focus on the creative aspects of design while benefiting from improved production efficiency in the DTF printing process.

Step-by-Step Guide to Creating Effective Gang Sheets

When building the perfect DTF gang sheet, the first step involves meticulous design planning. It’s crucial to use vector-based graphics for your designs to ensure sharpness and clarity, particularly when scaling images for the gang sheet. Additionally, software applications such as Adobe Illustrator or CorelDRAW are highly recommended for creating these sheets, as they provide the necessary tools for precise layout and adjusting spacing between designs.

Once the designs are laid out, the next step is to test print before committing to a full batch. This ensures proper calibration of the printer settings and avoids potential issues such as smudging or misalignment. By following these steps carefully, you can produce a high-quality DTF gang sheet that maximizes print efficiency and enhances the overall output of your projects.

Optimizing Printer Settings for DTF Printing

The DTF printing process relies heavily on optimal printer settings to achieve vibrant and precise results. Adjusting ink density is a critical step, as using too much can lead to smudging, while too little can result in faded prints. Additionally, ensuring that the color profiles are configured correctly to match the DTF film used will help maintain color accuracy, making a significant impact on the final product’s quality.

Another important setting to consider is the print speed. While faster speeds may seem beneficial for productivity, it is essential to strike a balance between speed and print quality. Testing various settings before the final production run is crucial for achieving the best results and can dramatically influence the print’s final appearance and durability.

Material Selection for High-Quality DTF Prints

Choosing the right materials is paramount in DTF printing, particularly when it comes to the film and adhesive powder. High-quality DTF film that is durable and compatible with your printer is essential for vibrant prints that withstand washing and wear over time. The adhesive powder used is equally important, as it plays a significant role in the transfer process and can affect the overall quality of the print.

Before finalizing material choices, conducting test samples is highly recommended. This allows you to verify the compatibility of the film and adhesive powder, ensuring that they work harmoniously with your designs and printer settings. By investing time in material selection and testing, you can maintain high standards of quality for your DTF prints.

Post-Printing Procedures for Longevity

Once the DTF gang sheet is printed, following the proper post-printing procedures is critical for preserving the integrity of the prints. Curing the transfers immediately after printing is necessary, as it helps set the ink and adhesive properly. Always refer to the manufacturer’s guidelines for the ideal curing time and temperature settings to avoid compromising quality.

After curing, it’s equally important to allow prints to cool down before handling them. This meticulous care helps prevent smudging and maintains the vibrancy of the colors. Proper storage of the completed prints in a cool, dry environment will further enhance their longevity and keep them in pristine condition for future distribution or use.

Frequently Asked Questions

What is a DTF gangsheet and why is it important in DTF printing?

A DTF gangsheet is a printing method that allows multiple designs to be printed simultaneously on a single film sheet in the Direct-to-Film (DTF) printing process. It is important as it maximizes print efficiency, reduces costs by minimizing material use, and decreases waste, making it ideal for both small and large scale printing operations.

How do I create the perfect DTF gangsheet for my designs?

To create the perfect DTF gangsheet, start with effective design considerations such as ensuring proper spacing between designs to prevent overlaps. Use vector-based graphics for high-quality prints, and utilize software like Adobe Illustrator or CorelDRAW that supports gang sheet layouts to optimize your printing process.

What are the benefits of using gang sheets in DTF printing?

Gang sheets in DTF printing provide several benefits: they improve print efficiency by allowing multiple designs to be printed at once, they are cost-effective due to the reduced material usage, and they minimize waste, which is better for both your business’s bottom line and the environment.

What printer settings should I adjust for optimal DTF gangsheet printing?

For optimal DTF gangsheet printing, adjust your printer settings by calibrating the ink density to achieve vibrant colors without smudging. Ensure that your color profiles are correctly set for the DTF film, and test print speeds to balance quality and efficiency without compromising print outcomes.

What materials should I choose for successful DTF gangsheeT printing?

When selecting materials for DTF gangsheet printing, use high-quality DTF film that offers durability and vibrant color retention. Moreover, choose the appropriate adhesive powder based on your printer settings and the type of film you are using, and always conduct test prints to ensure material compatibility.

What post-printing procedures should I follow after printing a DTF gangsheet?

After printing a DTF gangsheet, it is crucial to follow proper post-printing procedures: cure the prints immediately as per the manufacturer’s guidelines for time and temperature, allow the prints to cool to prevent smudging, and store them in a cool, dry place away from direct sunlight to maintain quality.

| Key Point | Description |

|---|---|

| Definition of DTF Gangsheet | A method to print multiple designs on a single film sheet, optimizing resource use. |

| Benefits of Gangsheet | Increases efficiency, lowers costs, and reduces waste by minimizing unused areas. |

| Design Considerations | Focus on spacing, use vector graphics, and the right software for layout. |

| Optimal Printer Settings | Manage ink density, color profiles, and print speed for quality output. |

| Material Selection | Use high-quality DTF film and adhesive powder, and test samples before production. |

| Post-Printing Procedures | Follow proper curing, cooling, and storage to maintain quality. |

| Industry Trends | Stay updated on advancements like large-format printers to enhance operations. |

Summary

DTF gangsheet is a pivotal component for anyone stepping into the Direct-to-Film printing world. This guide walks you through the essential steps for creating effective gang sheets that boost efficiency, reduce costs, and minimize waste. By meticulously planning your designs, optimizing your printer settings, selecting quality materials, and adhering to post-printing practices, you elevate the quality of your prints while streamlining your workflow. The DTF printing landscape is constantly evolving, and mastering the art of gang sheets not only improves your immediate output but also positions your print shop favorably in an increasingly competitive market.