In the realm of custom apparel printing, the **DTF printing process** has revolutionized how designs are applied to fabrics. This innovative technique, known as Direct-to-Film printing, stands out for its ability to produce vibrant, high-quality prints suitable for various materials. As we delve deeper into DTF printing technology, we’ll uncover the essential steps involved, ensuring your custom designs are not only striking but also durable. With the best DTF printers available on the market today, achieving precision and speed is more accessible than ever. Moreover, this eco-friendly printing method aligns with sustainable practices, making it an ideal choice for today’s environmentally conscious consumer.

When it comes to the intricacies of fabric printing, Direct-to-Film (DTF) printing offers a nuanced approach that caters to a wide variety of materials. This modern printing method employs advanced techniques to transfer intricate designs onto textiles, enhancing the custom apparel experience. By leveraging state-of-the-art DTF printer technology, professionals can attain exceptional color richness and print durability. Not only does this method embrace customization, but it also integrates eco-conscious principles, appealing to a broader audience. Understanding the various DTF printing steps can empower businesses to create standout products that resonate within the competitive apparel market.

The Evolution of DTF Printing Technology

DTF printing technology has evolved significantly over the years, establishing itself as a leading method for custom apparel printing. Initially introduced as a niche solution, it has gained traction for its ability to produce vibrant designs on a variety of fabrics. Unlike traditional methods, which often require multiple screens and an extensive setup, the DTF process allows for quick adaptations and printing of intricate, colorful designs directly on film, which is later transferred to the fabric.

Recent advancements have improved print quality and speed, making DTF a preferred choice among garment decorators. Innovations in printing machinery, as well as water-based inks, have significantly enhanced color vibrancy and durability, ensuring that designs remain intact even after numerous washes. Furthermore, the technology’s flexibility permits customization options that cater to a wide array of market needs—whether for small businesses or large-scale apparel production.

Frequently Asked Questions

What is the DTF printing process and how does it work?

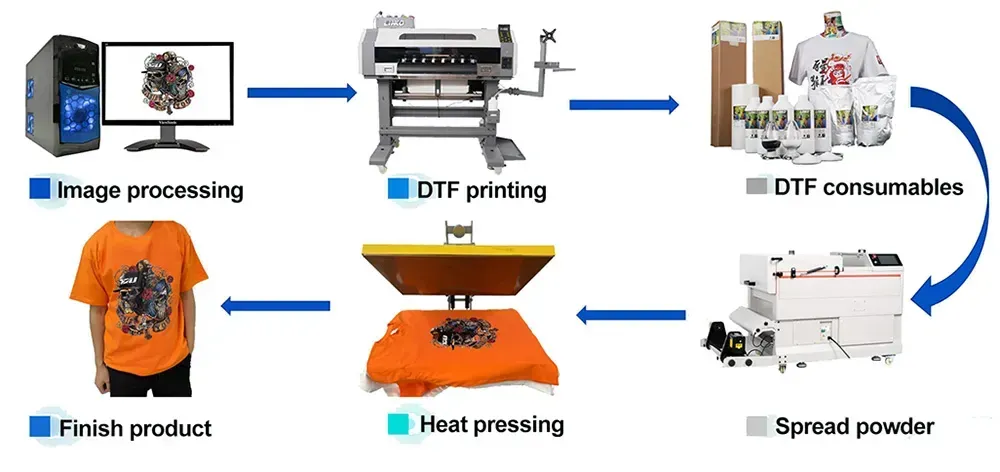

The DTF printing process, or Direct-to-Film printing, involves several key steps: creating a design, printing it onto specialized DTF film using best DTF printers, applying adhesive powder to the ink, curing the adhesive, transferring the design onto apparel, and finally peeling away the film. This process allows for vibrant prints on various fabrics, ideal for custom apparel printing.

What are the key benefits of DTF printing technology over traditional methods?

DTF printing technology offers numerous benefits, including the ability to print vibrant colors on diverse fabrics, flexibility in design creation, and faster production times. Additionally, DTF printing is known for its durability and compatibility with eco-friendly printing practices, making it a popular choice for custom apparel.

How can I start using DTF printing steps in my business?

To incorporate DTF printing steps in your business, you need to invest in the best DTF printers, acquire specialized DTF film, and learn the process from design creation to transfer. It’s essential to familiarize yourself with each step, including printing, applying adhesive, curing, and final product quality control, to ensure high-quality custom apparel.

Is DTF printing eco-friendly and sustainable?

Yes, DTF printing is increasingly recognized for its eco-friendly printing capabilities. Many manufacturers are now using non-toxic inks and sustainable materials in the DTF printing process to align with consumer expectations. This commitment to sustainability helps businesses enhance their brand loyalty while appealing to eco-conscious customers.

What types of fabrics are best suited for the DTF printing process?

The DTF printing process is versatile and works well on a variety of fabrics, including cotton, polyester, blends, and even leather. This flexibility in fabric compatibility makes DTF printing an excellent choice for custom apparel printing across different garment types and styles.

What advancements have been made in DTF printing technology recently?

Recent advancements in DTF printing technology include faster print speeds, improved ink formulations for vibrant colors, and enhanced adhesive powders for better adhesion and durability. These innovations have significantly improved the efficiency and quality of the DTF printing process, catering to the growing demand for custom apparel.

| Step | Description | Key Considerations |

|---|---|---|

| 1. Design Creation | Creating designs using graphic software like Adobe Illustrator. | Use powerful software for intricate designs. |

Summary

The DTF printing process is a multifaceted approach that merges creativity with technology, paving the way for high-quality, custom apparel. As advancements in sustainability and customization gain momentum, DTF printing remains a front-runner in shaping the future of printing in the textile industry. Brands looking to stay competitive should embrace these innovations, aligning their strategies with both market demands and environmental considerations. By following this step-by-step guide, businesses can successfully harness the potential of DTF printing to deliver exceptional products that resonate with today’s conscious consumers.