DTF printing techniques, also known as Direct-to-Film printing methods, have revolutionized the landscape of textile preparations. Whether you’re an entrepreneur in the apparel industry or a creative soul looking to personalize your wardrobe, understanding these innovative printing techniques is crucial. Not only do these methods ensure vibrant and long-lasting prints, but they also embrace eco-friendly inks and automated printing systems that streamline the process. In this article, we will delve into the top five DTF printing techniques, showcasing how they can help achieve stunning results while prioritizing sustainability and efficiency. Discover the transformative power of DTF printing and elevate your garment designs like never before.

Diving deeper into textile customization, direct-to-film methods represent a cutting-edge approach that blends creativity with precision. This advanced printing technology enables the transfer of intricate designs onto a variety of materials, yielding stunning visuals that stand the test of time. From utilizing specialty inks to employing automated systems for efficient production, these methods have piqued the interest of many in the printing community. As we explore the various techniques involved in this process, you’ll gain insights into how traditional heat transfer printing is evolving into a more versatile and eco-conscious practice. Embrace the future of printing and unleash your creative potential with these innovative techniques.

Exploring the Benefits of DTF Printing

DTF printing has emerged as a front-runner in the textile printing industry, offering a plethora of advantages that appeal to both professional printers and hobbyists. One of the main benefits of DTF printing is its ability to produce high-quality images with vibrant colors and exceptional detail. Since the designs are printed on a specially coated film, they can be transferred onto various fabrics, ranging from cotton to polyester, without losing the integrity of the print. This versatility makes DTF printing an ideal choice for a wide range of applications, including custom apparel and promotional merchandise.

In addition, DTF printing techniques boast impressive durability. The prints are made using heat and pressure, leading to designs that are not only long-lasting but also resistant to fading and cracking, even after numerous washes. This characteristic is particularly important for businesses aiming to provide reliable products to their customers. Furthermore, DTF allows for lower production costs and reduced waste, making it an appealing option for environmentally conscious creators who prioritize sustainability in their practices.

Key DTF Printing Techniques for Professionals

Among the various DTF printing methods, the double-print technique is particularly noteworthy for its ability to enhance visual appeal. By applying two layers of the same design onto the film, printers can achieve a depth and vibrancy that captivates viewers. This technique is especially effective on darker substrates, where the richness of the colors can significantly improve. It reflects the sophistication expected by professional workers aiming to deliver superior quality prints, making it invaluable in high-stakes printing environments.

Layering is another powerful technique that stands out in the realm of DTF printing. By combining multiple prints, designers can create unique textures and visual effects that elevate their designs. This method allows for creativity and complexity, appealing to brands and businesses that wish to distinguish themselves from competitors. Additionally, layering can highlight different characteristics like sheen and matte finishes, contributing to an overall professional touch that has become essential in the competitive garment industry.

Incorporating Eco-Friendly Inks in DTF Printing

As the demand for sustainable practices rises within the printing industry, the adoption of eco-friendly inks has gained momentum in DTF printing. Water-based and vegetable-based inks not only provide vibrant colors but also help reduce the carbon footprint of the printing process. By utilizing these inks, businesses can meet the growing consumer preference for greener products and enhance their sustainability profile. The use of eco-friendly inks is not just a trend, but rather a necessary shift that aligns with global movements toward environmental responsibility.

Moreover, these specialty inks allow for improved print quality when using DTF techniques. Their formulation enables better adhesion to fabrics, leading to designs that are both visually stunning and ethically sound. Integrating eco-friendly inks into DTF printing processes exemplifies a commitment to innovation and sustainability, positioning businesses as leaders in eco-conscious practices and appealing to an increasingly aware customer base.

Current Trends Influencing DTF Printing

The printing industry is continually evolving, and staying abreast of current trends is vital for success. One significant trend in DTF printing is an increased focus on customization. The ability to produce tailored designs for customers has surged in popularity, allowing businesses to offer personalized apparel and unique promotional items. This trend caters to the modern consumer’s desire for individuality and self-expression, thus driving demand for DTF printing services that can deliver customized products efficiently.

Another trend is the rise of automated printing systems within DTF printing operations. These systems streamline the production process, reducing labor costs and enhancing precision. Automation not only contributes to consistency in quality but also elevates output efficiency, which is increasingly important for businesses handling large printing orders. As printers employ automated systems, they can dedicate resources toward creative development rather than repetitive tasks, further enriching the overall quality of designs.

Advantages of Heat Transfer Techniques in DTF Printing

Heat transfer printing, closely related to DTF printing, provides several advantages that enhance the overall printing experience. DTF techniques leverage the power of heat to securely apply prints onto textiles, creating enduring designs that hold up well over time. The integration of heat transfer into DTF processes ensures that prints remain vibrant and intact through multiple washes, making them suitable for garment manufacturing and other applications requiring durability.

Moreover, the straightforward application of heat transfer methods within DTF printing simplifies the entire process. This allows printers to effectively manage high-volume production runs without sacrificing quality. With the ability to achieve consistent results, businesses can reliably meet customer demands, further establishing their reputation in the industry. The commitment to quality and dependability in heat transfer printing techniques is a key component of success in a competitive marketplace.

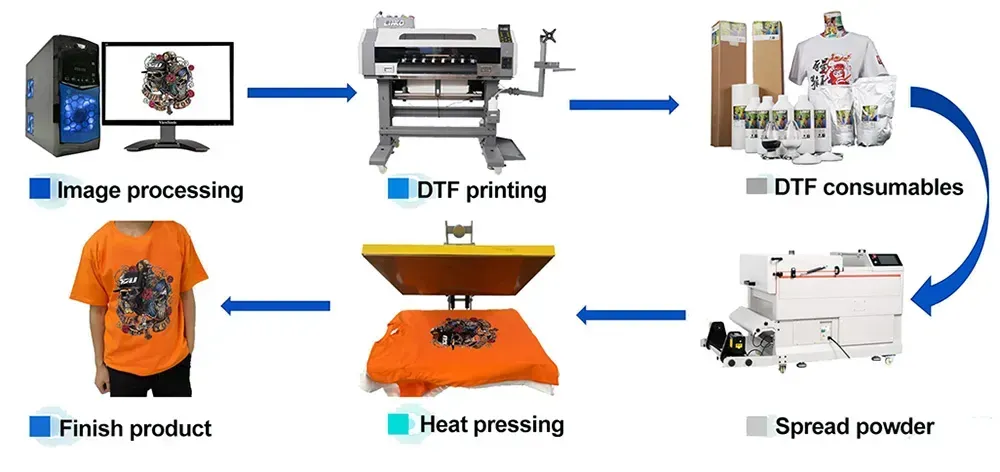

Understanding the Process of DTF Printing

Understanding the DTF printing process is essential for anyone looking to succeed in the garment printing business. The initial steps involve printing a design onto a special synthetic film using advanced inkjet technology. The use of specialized inks ensures that the colors are bright and will adhere well to different fabric types. After printing, the design is covered in a powder adhesive, which is then cured using heat. This step is crucial, as it prepares the print for transfer onto fabric, aiding in durability and adherence.

Once the adhesive is applied, the DTF transfer process is completed by pressing the film onto the desired textile material using a heat press. This method guarantees that the ink merges with the fabric fibers, resulting in high-resolution, vivid designs that stand the test of time. Understanding each stage in the DTF printing process empowers creators and businesses to fine-tune their operations for maximum impact and efficiency, ensuring that they can meet diverse customer needs while producing top-quality products.

Frequently Asked Questions

What are the benefits of using DTF printing techniques in textile manufacturing?

DTF printing techniques provide numerous benefits in textile manufacturing, including the ability to create vibrant and durable designs on a variety of fabrics. The process of Direct-to-Film (DTF) printing allows for efficient high-quality prints that can withstand multiple washes due to the heat transfer application. Additionally, DTF printing methods support the use of eco-friendly inks, appealing to environmentally conscious consumers.

How does the double-print technique enhance DTF printing results?

The double-print technique in DTF printing enhances results by allowing the same design to be printed twice onto the film. This overlapping of ink layers significantly increases color vibrancy and opacity, especially on dark fabrics. As a result, your designs become more striking and eye-catching, making this technique ideal for those looking to make a bold impression.

What role do eco-friendly inks play in DTF printing methods?

Eco-friendly inks play a crucial role in DTF printing methods as they contribute to sustainable printing practices. These inks not only produce vibrant colors but also minimize environmental impact by reducing toxic waste. Utilizing eco-friendly inks aligns with the growing demand for sustainable textiles, making it a key consideration for businesses aiming to attract environmentally aware consumers.

Can you explain the heat transfer application process in DTF printing?

The heat transfer application process in DTF printing involves applying a printed film onto fabric using a heat press. This method seals the design onto the material, ensuring durability and longevity by preventing fading after multiple washes. Heat transfer printing in DTF is highly valued for its straightforward application and consistent results, making it effective for both small and large production runs.

What are automated DTF systems, and how do they improve printing efficiency?

Automated DTF systems revolutionize the Direct-to-Film printing process by streamlining operations and enhancing efficiency. These systems facilitate consistent print quality across large volumes, significantly reducing labor costs and production time. As a result, businesses can increase their output without compromising quality, making automated systems a valuable investment in the fast-paced garment printing industry.

How can layering prints elevate the quality of DTF printed designs?

Layering prints is a technique in DTF printing that adds depth and texture to designs. By stacking multiple prints, you can create intricate graphics with a unique character, enhancing visual appeal. This method is particularly effective for complex designs or those requiring a three-dimensional look, allowing artists and printers to elevate the quality and creativity of their printed products.

| DTF Printing Technique | Description |

|---|---|

| Double-Print Technique | Enhances vibrancy and opacity by printing the same design twice on the film, especially effective on dark fabrics. |

| Layering Prints | Creates depth and texture by layering multiple prints, ideal for intricate designs. |

| Heat Transfer Application | Uses heat presses to apply printed films to textiles, ensuring durability and resistance to fading. |

| Use of Specialty Inks | Incorporates water-based and eco-friendly inks for vibrant finishes while promoting sustainability. |

| Automated DTF Systems | Increases efficiency and accuracy in printing, allowing for high-volume production while maintaining quality. |

Summary

DTF printing techniques are revolutionizing the fabric printing industry, enabling both amateurs and experts to achieve stunning results with their designs. The five pivotal techniques discussed—double-print, layering, heat transfer application, use of specialty inks, and automated DTF systems—highlight the versatility and innovative potential of DTF printing. As this method continues to evolve, staying informed about advanced techniques and trends is key to creating remarkable products that stand out in today’s competitive market.