DTF transfers, or Direct-to-Film transfers, are revolutionizing the world of textile printing with their innovative approach to high-quality and sustainable apparel production. This cutting-edge printing technique offers numerous benefits, including exceptional durability and vibrancy in designs, making it a game-changer for brands eager to attract environmentally conscious consumers. Unlike traditional methods, DTF transfers allow for on-demand printing that minimizes waste and promotes sustainable practices in the fashion industry. With the capability to customize designs to meet individual customer preferences, DTF also fosters a new wave of personalization in the clothing market. Let’s explore the fascinating world of DTF transfers and discover why they are becoming the preferred choice for textile printing.

In the realm of modern textile printing, the emergence of Direct-to-Film (DTF) methods signifies a pivotal shift toward enhanced production techniques. Often hailed for their versatility, these advanced printing solutions enable seamless application of designs directly onto fabric via film, ensuring vivid results that stand the test of time. As the demand for eco-friendly practices rises, DTF technology stands out by significantly reducing material waste compared to conventional printing methods. Furthermore, the adaptability of this process allows for intricate designs, setting new standards in high-quality custom apparel. By embracing these innovative printing strategies, brands can not only uphold sustainability but also engage customers through personalized experiences.

Understanding the DTF Printing Process

Direct-to-Film (DTF) printing represents a unique method of transferring vivid designs onto various fabrics. This innovative process begins by printing the desired artwork onto a special film using high-quality ink. The printed film is then treated with an adhesive powder that helps bond the ink to the fabric during the heat transfer phase. Once the film is prepared, it is placed on the fabric and exposed to heat and pressure, which activates the adhesive and transfers the design, ensuring that the colors are sharp and detailed. This method offers a stark contrast to old-fashioned printing techniques, contributing to a cleaner and more efficient production environment.

Moreover, the DTF printing process excels in its versatility, suitable for multiple fabric types including cotton, polyester, and blends. This adaptability not only enhances its functionality in the apparel industry but also augments options for custom products. The ability to print intricate designs with robust color output meets the demand for high-quality textile printing, making DTF a preferred choice among manufacturers aiming to stand out in a competitive market.

Key Benefits of DTF Printing for Sustainable Apparel

The benefits of DTF printing extend beyond mere aesthetics; it significantly contributes to sustainability in apparel manufacturing. Traditional printing methods often result in substantial waste, from excess ink to unused fabric. However, with DTF transfers, brands can implement on-demand production which minimizes material waste. By only producing garments based on current consumer demand, companies not only cut down on excess inventory but also align themselves with the growing consumer preference for eco-friendly practices.

Additionally, DTF technology utilizes less water and fewer harmful chemicals compared to conventional screen printing, further reducing the environmental footprint of textile production. As sustainability trends gain traction globally, incorporating DTF printing will not only appeal to eco-conscious customers but also enhance a brand’s image in the marketplace. This shift towards environmentally friendly manufacturing processes makes DTF a significant player in the future of sustainable apparel printing.

Achieving Exceptional Print Quality with DTF

When it comes to print quality, DTF transfers shine compared to other textile printing techniques. The unique printing process allows for an unprecedented level of detail, capturing both intricate designs and vibrant colors that resonate with consumers. Unlike some methods that may compromise color vibrancy under pressure, DTF ensures that prints remain rich and long-lasting, making them more appealing for fashion-forward brands.

Furthermore, the durability of DTF prints makes them suitable for everyday wear, withstanding multiple washes without fading or deteriorating. This high-quality output can enhance customer satisfaction and loyalty, as consumers appreciate products that not only look good upon purchase but retain their appeal over time. By integrating DTF technology into their production, brands can commit to delivering superior, high-quality textile printing that their customers will love.

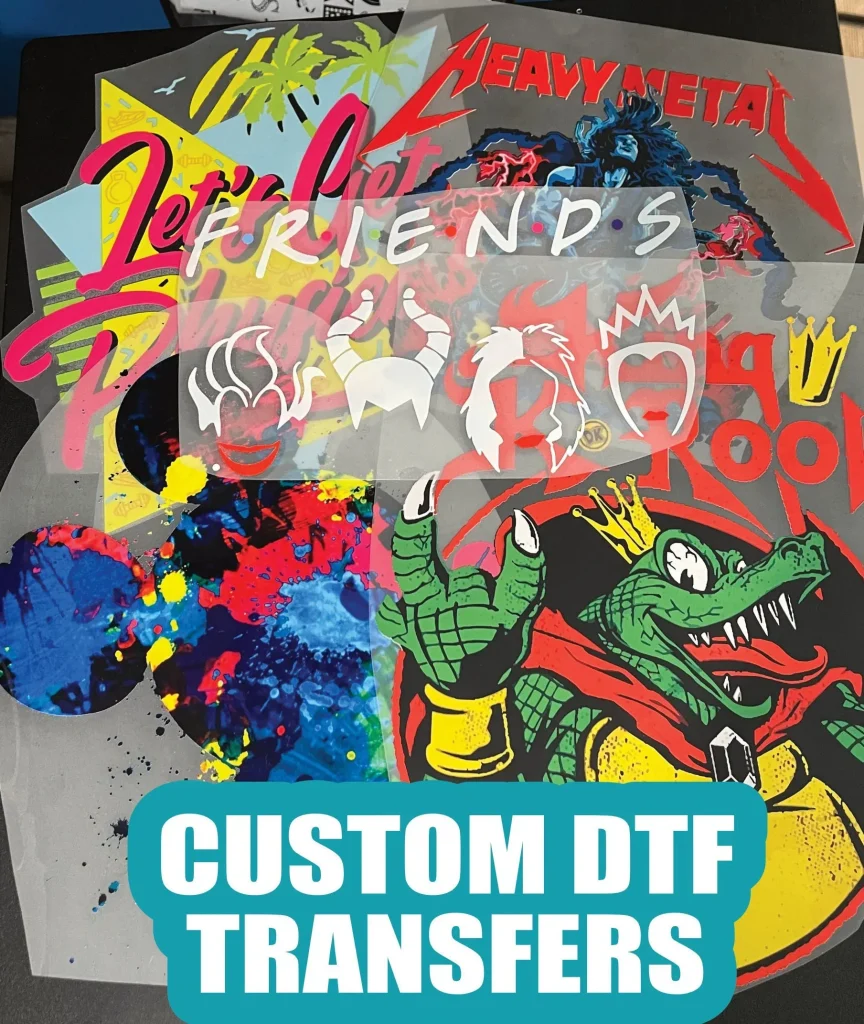

Customization Options Available with DTF Transfers

One of the standout features of DTF printing is its exceptional customization capabilities. In a market where personalization is increasingly valued, DTF allows brands to easily cater to unique customer needs without the logistical issues of maintaining large stock inventories. This flexibility ensures that businesses can quickly adapt to changing trends or specific customer requests, providing tailored designs that resonate on a personal level.

For example, small businesses leveraging DTF technology can fulfill custom orders for events or create unique merchandise that reflects individual styles. This on-demand approach not only enhances customer experience but also drives sales through bespoke offerings. As manufacturers recognize the competitive edge that customization provides, investing in DTF transfers becomes a strategic move to differentiate themselves in a crowded marketplace.

The Growing Impact of DTF Technology on the Apparel Industry

DTF printing technology is making significant strides in transforming the apparel landscape, particularly as innovative companies invest heavily in it. The ability of DTF to produce high-quality prints at scale has led to expanded capabilities, making it an attractive option for both large and small manufacturers alike. Through the adoption of DTF, businesses are discovering new avenues for growth while addressing efficiency and quality simultaneously.

Industry experts predict that advancements in DTF technology—including improved inks and printing methods—will continually influence the manufacturing process, creating a ripple effect throughout the apparel industry. As the demand for high-quality, customizable, and sustainable products increases, DTF’s role will only grow, further solidifying its status as a leading technology in textile printing.

Future Trends: The Evolution of DTF Printing in Textile Production

As the textile industry evolves, Direct-to-Film (DTF) printing is poised to play a pivotal role in shaping future trends. With environmental awareness at an all-time high, brands are seeking solutions that not only reduce waste but also enhance production efficiency. DTF technology’s ability to combine these elements positions it as a front-runner in the next wave of textile innovation.

In addition, as consumer preferences shift towards unique, high-quality apparel, the flexibility offered by DTF transfers allows brands to stay ahead of market demands. Companies that adopt DTF are likely to see improvements in customer engagement and satisfaction rates, as they can respond swiftly to trends and personalize their offerings effectively. The ongoing evolution of DTF printing will continue to redefine standards within the apparel industry, encouraging a more sustainable and consumer-oriented future.

Frequently Asked Questions

What are DTF transfers and how do they work in textile printing?

DTF transfers, or Direct-to-Film transfers, are a modern printing method where designs are printed onto a specialized film and then heat-pressed onto fabrics. This technique allows for vibrant colors and intricate details, making it a preferred choice for high-quality textile printing including apparel and promotional items.

What are the sustainability benefits of using DTF printing technology?

DTF printing technology promotes sustainability by minimizing waste during production. Unlike traditional textile methods, DTF allows businesses to print on demand, producing only what is necessary and significantly lowering material waste. This eco-friendly approach is gaining traction as consumers increasingly favor sustainable apparel options.

How does DTF printing achieve high-quality results compared to other methods?

DTF transfers achieve exceptional print quality due to their ability to produce sharp, vivid imagery that withstands multiple washes without fading. This method accommodates various fabric types while maintaining vibrancy and detail, ensuring high-quality results that appeal to both manufacturers and consumers.

What makes customization in DTF printing an important trend in the apparel market?

Customization in DTF printing is crucial for meeting consumer demands for personalized products. DTF allows brands to easily create tailored designs for unique customer requests without needing large inventories, enhancing customer satisfaction and providing businesses a competitive edge in customization and quick response.

What are the key advantages of adopting DTF transfers in the apparel industry?

The key advantages of adopting DTF transfers include sustainability through reduced waste, high-quality printing results, and the capability for customization. These benefits not only improve brand reputation but also align with current consumer preferences for eco-friendly and unique apparel options.

How are businesses evolving with DTF technology in textile printing?

Businesses in the textile industry are evolving by investing in DTF technology to improve efficiency, reduce environmental impact, and expand product offerings. As companies like EazyDTF enhance their capabilities, DTF is becoming a significant player, setting new standards for quality and sustainability in textile printing.

| Aspect | Details |

|---|---|

| What are DTF Transfers? | A printing method where designs are printed on special film and then transferred to fabric using heat and pressure, allowing for detailed and colorful designs. |

| Sustainability | Minimizes waste through on-demand printing, producing only what is needed and aligning with eco-friendly practices. |

| High-Quality Results | Delivers sharp, vivid images that are durable and look great on a variety of fabrics. |

| Customization | Allows for personalized products with no need for large inventories, catering to individual customer needs. |

| Industry Developments | Growing recognition of DTF’s potential, with significant investments from companies leading to improvements in quality and process efficiency. |

Summary

DTF transfers are revolutionizing textile printing by offering a sustainable, high-quality, and customizable printing solution. This innovative technology minimizes waste, producing only what’s necessary and catering to environmentally conscious consumer demands. The exceptional print quality ensures long-lasting and vibrant designs on various fabrics, making it an invaluable tool for brands aiming to stand out in a competitive market. With the capability to personalize products effortlessly, DTF transfers meet the growing trend for customized apparel. As industry players increasingly adopt this technology, it becomes clearer that DTF transfers are essential for modern apparel production and shaping the future of textile manufacturing.