DTF Transfers, or Direct to Film transfers, have emerged as a modern solution in the realm of custom apparel printing, offering a unique method for transferring vivid designs onto various fabrics. This innovative technique utilizes specialized films and printers to create high-quality designs that are perfect for garment printing. With the DTF printing process, users experience a seamless blend of vivid colors and intricate details, making it a favorite among both small-scale businesses and larger operations. By focusing on optimizing the printing process, entrepreneurs can leverage this versatile method to enhance their product offerings, catering to the growing demand for personalized apparel. As the demand for custom graphics surges, understanding DTF Transfers becomes crucial for those looking to excel in the competitive landscape of textile printing.

Exploring alternatives to traditional printing methods, the Direct to Film technique offers a contemporary approach to applying designs onto textiles. Often referred to as DTF printing, this method stands out among garment printing techniques for its ability to deliver exceptional quality and versatility across an array of materials. By employing a specialized film to transfer images, this innovative process ensures that custom designs capture the attention of consumers seeking one-of-a-kind apparel. Whether you’re a small business eager to create unique items or a large printing operation looking for efficiency, utilizing techniques like DTF transfers can optimize your production capabilities. This growing trend in custom graphic application not only enhances the visual appeal of products but also boosts marketability in a crowded industry.

Understanding the DTF Printing Process

The Direct to Film (DTF) printing process is revolutionary in the realm of custom apparel printing. It starts with the creation of a high-resolution design that is printed onto a specially coated transfer film. This is done using advanced DTF inks, highly pigmented and designed to provide vibrant colors. The critical phase comes after printing when an adhesive powder is applied to the wet inks, bonding them to the film. This meticulous process ensures that the final graphics boast both durability and aesthetic appeal, making it an exceptional choice for anyone interested in high-quality garment printing.

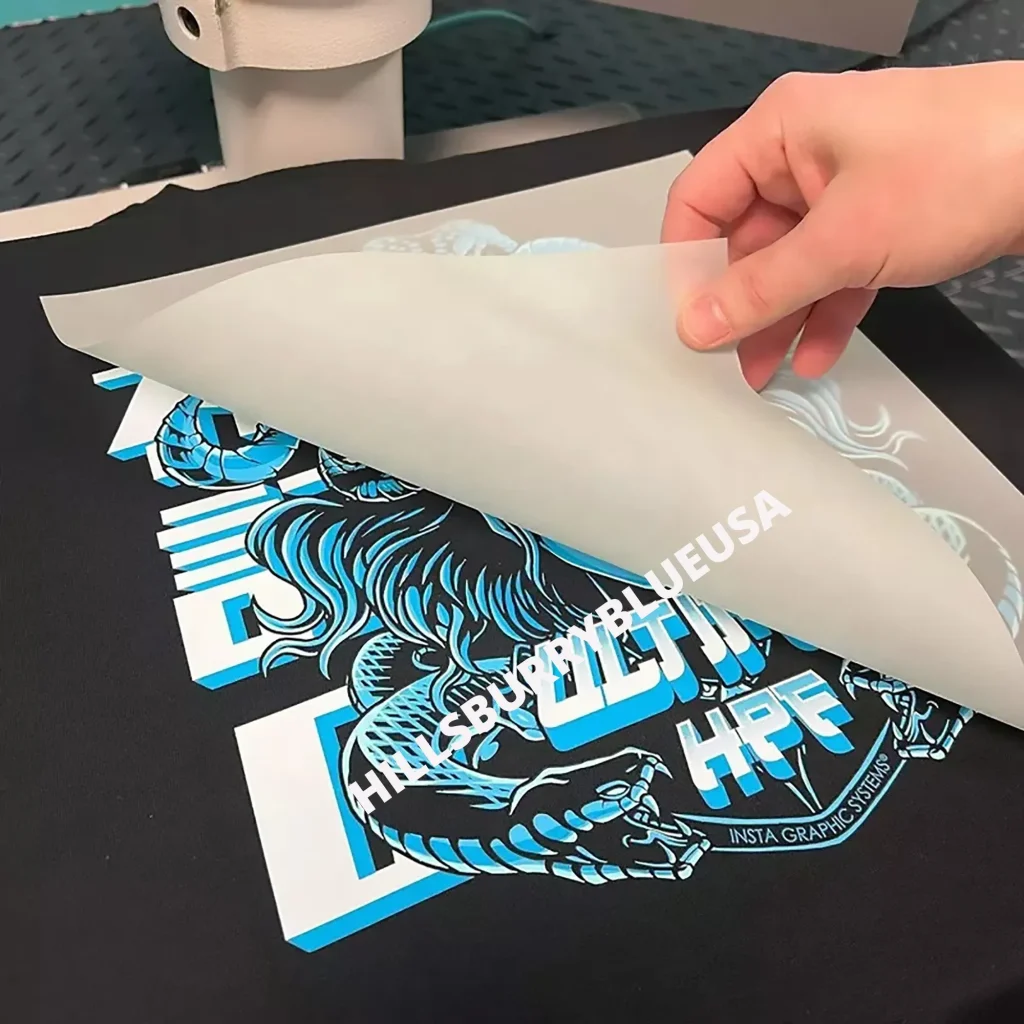

Once the adhesive is applied, the film must be cured under specific heat settings, which solidifies the adhesive and prepares it for transfer. After curing, the film is ready to be pressed onto the fabric using a heat press. The combination of heat and pressure facilitates a seamless transfer of the design onto various materials, from cotton to polyester blends. Understanding this intricate process not only highlights the capabilities of DTF printing but also the importance of attention to detail in achieving superior results.

Frequently Asked Questions

What are DTF Transfers and how do they work in garment printing?

DTF Transfers, or Direct to Film Transfers, involve printing a design onto a special film using DTF printers, then using heat and pressure to apply the design onto fabrics. This method produces high-quality images on various materials and is celebrated for its vibrant colors and detail.

What are the advantages of using DTF printing over other garment printing techniques?

DTF printing offers several advantages, including its versatility across various fabric types, ability to create detailed and colorful designs, and cost-effectiveness for small production runs, making it ideal for custom apparel printing.

How can I optimize my DTF printing process for better results?

To optimize your DTF printing process, ensure you use high-quality DTF inks and films, regularly maintain and calibrate your printer, accurately apply adhesive powder, and adjust temperature and pressure settings based on the fabric type.

What fabrics are suitable for DTF Transfers?

DTF Transfers can be applied to a wide range of fabrics, including cotton, polyester, and blends, making it suitable for various garment printing applications such as t-shirts, bags, and other custom apparel.

Are there any sustainability measures in DTF printing?

Yes, the DTF printing industry is increasingly focusing on sustainability, with many manufacturers offering eco-friendly DTF inks and films that align with the growing trend toward sustainable practices in custom apparel printing.

What is the role of adhesive powder in the DTF printing process?

Adhesive powder is crucial in DTF printing as it bonds the ink to the fabric during the transfer process. The correct application of adhesive ensures the durability and quality of the printed design on garments.

| Key Point | Description |

|---|---|

| Process Description | DTF involves printing onto a film, applying adhesive, curing it, and employing a heat press to transfer the design onto fabric. |

| Advantages of DTF Printing | DTF is versatile, creates vivid designs, and is cost-effective for small batch printing. |

| Optimizing the Printing Process | Using quality materials, calibrating printers, and fine-tuning settings are essential for achieving the best results. |

| Current Trends | Focus on sustainability and technological advancements is shaping the DTF industry. |

| Market Growth and Application | DTF printing is expanding due to increased demand for personalized products. |

Summary

DTF Transfers are revolutionizing the textile printing sector with their ability to deliver high-quality, vibrant designs on a variety of fabrics. This technique not only meets the diverse needs of businesses from small startups to larger enterprises, but it also champions sustainability with eco-friendly options. The DTF transfer process is increasingly favored for its efficiency and cost-effectiveness, making it a preferred choice for custom apparel and promotional items. As DTF technology continues to advance, staying informed about the latest practices and materials is crucial. Those willing to invest in quality and optimization will find DTF transfers to be an invaluable asset for enhancing their printing capabilities.