DTF transfers, or Direct-to-Film transfers, have emerged as a revolutionary force in the realm of textile printing, blending innovation with practicality. This cutting-edge printing technology allows for the creation of stunning, high-definition designs that are applicable to a diverse range of fabrics, making it a top choice for custom apparel brands. The benefits of DTF printing extend beyond mere aesthetics, offering businesses a cost-effective solution that aligns with the growing demand for sustainable printing methods. As more companies recognize the versatility and quality of DTF transfers, it’s clear that this approach to textile printing is fast becoming a preferred method in the industry. Dive into the world of DTF transfers and discover how this game-changing technology is reshaping the future of fabric design and printing.

In the exciting landscape of modern textile fabrication, Direct-to-Film technology stands out for its innovative approach to printing. Often referred to simply as film transfers, this method allows for vibrantly detailed visuals to be produced on a variety of materials, catering effectively to the custom apparel market. The remarkable advantages of this printing technique position it as a staple for businesses looking to promote their unique brand identities through high-quality designs. Moreover, with an increasing focus on eco-friendly production methods, the sustainable nature of film-based printing solutions aligns perfectly with the values of today’s environmentally conscious consumers. Join us as we explore the numerous facets of Direct-to-Film technology and its transformative impact on the textile printing industry.

Understanding DTF Transfers

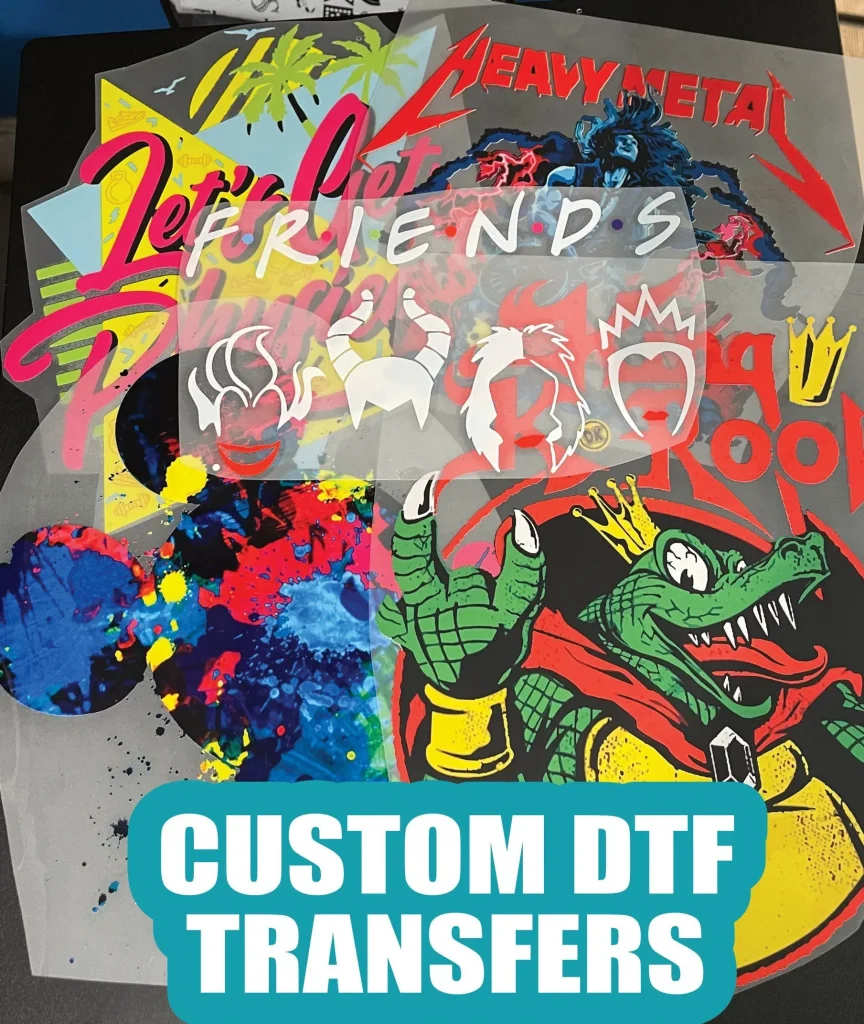

Direct-to-Film (DTF) transfers represent a transformative leap in the realm of textile printing technology. By allowing designs to be printed directly onto a film material, DTF empowers printers to achieve extraordinary detail and color vibrancy without the limitations other methods impose. This innovative approach has caught the attention of the custom apparel industry, seeking high-quality printing solutions that can adapt to various fabric types. As a result, DTF transfers are becoming an essential tool for any business aiming to elevate their branding through detailed imagery.

In the evolving textile landscape, DTF technology stands out by improving the efficiency of the printing process. Unlike traditional methods that often require extensive setup and incur high costs, DTF provides a streamlined workflow that saves both time and resources. With a focus on sustainability and reduced waste, the adoption of DTF transfers aligns perfectly with modern consumers’ values. This makes them not only a practical choice but also a responsible one, appealing to eco-conscious businesses looking to improve their market reach.

The Benefits of DTF Printing in Custom Apparel

One of the standout features of DTF printing is its capacity to produce high-quality, custom designs that satisfy the unique needs of individual clients. This technology allows for intricate designs that can easily translate into vibrant colors on various fabric types, including cotton and polyester blends. This versatility in fabric compatibility—where other printing technologies like sublimation fall short—paves the way for businesses to cater to a diverse customer base, helping them stand out in the competitive custom apparel market.

Additionally, DTF transfers simplify the production process. Custom apparel businesses often face challenges in balancing quality and cost-effectiveness, particularly when it comes to small runs or one-off designs. However, DTF printing minimizes setup time and reduces the overall cost per item by eliminating the need for screens. This model not only enhances profitability for printers but also allows customers to enjoy personalized products without exorbitant pricing.

Taking customization a step further, DTF printing encourages creativity in design—enabling brands to offer a wide range of personalized options. This aligns perfectly with consumer trends that increasingly favor unique, personalized garments, making DTF transfers an indispensable asset for businesses focused on custom apparel.

Environmental Advantages of DTF Transfers

The textile printing industry is under growing pressure to adopt more sustainable practices as consumers become increasingly concerned about their environmental impact. DTF transfers address this issue head-on with their water-based inks, which significantly reduce harmful emissions and waste associated with traditional solvent-based inks. This eco-friendly approach resonates well with today’s environmentally conscious shopper and positions brands utilizing DTF as leaders in sustainable practices.

Moreover, the durability of DTF prints contributes to a more sustainable approach by extending the lifespan of printed apparel. The high-quality prints created using DTF technology have been shown to withstand repeated washes and wear. As a result, garments printed with DTF transfers can enjoy prolonged use, minimizing the need for replacements and further reducing waste. By choosing DTF, businesses can not only fulfill customer demand for high-quality apparel but also make a positive impact on the environment.

Challenges Associated with DTF Printing

While DTF printing has numerous advantages, it is important to acknowledge the challenges that can arise during the production process. Achieving optimal print quality requires precise calibration and ongoing maintenance of the printing equipment. Printer operators must also be trained to handle the nuances of DTF technology effectively, from selecting appropriate fabrics to ensuring proper application of adhesives. Without the right knowledge and skills, businesses may struggle to realize the full potential of DTF transfers.

Additionally, the variability of print results based on fabric choice can pose challenges for operators. Each type of material may react differently with the transfer inks, leading to potential inconsistencies in color vibrancy and adherence. It is crucial for businesses to engage in thorough testing and quality control to ensure that every printed piece meets their high standards while also meeting customer expectations.

Comparing DTF to Other Printing Methods

To truly appreciate the impact of DTF transfers, it is essential to compare them with other prevalent printing methods such as Direct to Garment (DTG) and screen printing. While DTG excels in producing soft prints with intricate detail, it often struggles to provide the vibrancy and durability seen with DTF. DTF printing, on the other hand, is especially advantageous for larger runs, where efficiency and cost savings are crucial, making it an attractive option for custom apparel businesses.

While screen printing remains a staple for high-volume orders, it lacks the versatility and quick turnaround times that DTF offers. The requirement for separate setups for each design in screen printing can slow down production and inflate costs, making DTF a more viable option for companies that thrive on customization and variety. As the textile printing market continues to evolve, understanding these differences helps businesses make informed decisions when choosing the right printing technology.

Future Trends in DTF Transfers

As we look towards the future of textile printing, the trend of DTF transfers is likely to grow more pronounced. With advancements in printing technology and increasing consumer demand for bespoke products, businesses leveraging DTF will find themselves in a strong position within the market. Ongoing innovations in DTF inks and adhesive technologies will further enhance color quality and durability, essential for meeting the standards set by discerning customers.

In addition to improvements in the technology itself, there is a growing trend towards integrating eco-friendly practices within the manufacturing process, significantly affecting how brands operate in the textile industry. The demand for sustainable printing solutions will push more businesses to adopt DTF transfers, aligning their operational practices with broader environmental goals. As a result, DTF printing is not just a temporary trend but represents a forward-thinking approach to high-quality, sustainable textile printing.

Frequently Asked Questions

What are the benefits of using DTF transfers in textile printing?

DTF transfers offer several key benefits in textile printing, including exceptional color vibrancy, intricate detail reproduction, and cost-effectiveness. Unlike traditional methods, DTF allows for quick production on a wide range of fabrics, making it ideal for custom apparel brands aiming to meet diverse market demands.

How does DTF printing compare to traditional screen printing?

DTF printing excels in versatility, allowing for designs on various fabric types without the setup costs associated with traditional screen printing. While screen printing may be more cost-effective for large runs, DTF’s ability to produce high-quality prints quickly makes it a favorable option for businesses focusing on customization and smaller orders.

Is DTF printing sustainable compared to other printing technologies?

Yes, DTF printing is generally considered more sustainable due to its use of water-based inks, which reduce environmental impact compared to solvent-based inks in other methods. This eco-friendly approach aligns with modern consumer preferences for sustainable printing practices.

What types of fabrics can DTF transfers be applied to?

DTF transfers can be applied to a wide variety of fabrics, including cotton, polyester, and their blends. This compatibility allows businesses to cater to diverse customer needs, making DTF printing an ideal choice for custom apparel across different fabric types.

How quickly can designs be produced using DTF transfers?

DTF transfers enable a quick turnaround time for printing, allowing businesses to produce custom designs rapidly. This speed is crucial for meeting tight deadlines and customer expectations, especially for promotional items that require immediate fulfillment.

What are some challenges associated with DTF printing?

While DTF printing has numerous advantages, it does present challenges, including the need for careful calibration and maintenance of the printing equipment. Additionally, print quality can vary based on the fabric used, necessitating ongoing training and knowledge for operators to achieve optimal results.

| Key Points | Details |

|---|---|

| 1. Exceptional Quality and Detail | DTF printing produces high-quality images with intricate details and vibrant colors, important for brands to stand out. |

| 2. Cost-Effective Solution | Minimizes setup costs and reduces waste, making it an ideal choice for small businesses. |

| 3. Versatile Fabric Compatibility | Compatible with cotton, polyester, and blends, allowing broader market reach. |

| 4. Quick Turnaround Time | Enables faster production times for custom orders, enhancing customer satisfaction. |

| 5. Eco-Friendly Approach | Uses water-based inks, offering a sustainable printing option. |

Summary

DTF Transfers are revolutionizing the textile printing industry by providing a combination of quality, versatility, speed, and cost-efficiency. This game-changing technology allows for bright, intricate designs to be printed on a wide variety of fabrics, catering to the diverse needs of the market. As consumer demand for personalized, sustainable products continues to rise, DTF printing stands out as a preferred solution for businesses aiming to thrive in today’s competitive landscape. The advantages of DTF Transfers make them a crucial innovation for the future of textile printing.