DTF transfers are transforming the landscape of custom apparel printing, offering small businesses innovative solutions for creating high-quality garments. By utilizing Direct to Film (DTF) technology, entrepreneurs can access cost-effective methods that produce vibrant and detailed designs suitable for a variety of fabric types. As a business owner exploring the world of DTF printing, understanding how to create these versatile transfers can set you apart from your competitors and elevate your brand presence. This guide will walk you through the essentials of starting your DTF transfers business, covering the necessary equipment and best practices tailored for aspiring printers. With the right approach, you can tap into the growing market for custom apparel while maximizing your creative potential.

Directional to Film transfers, also known as DTF printing, represents a breakthrough in the realm of print technology, especially for those venturing into the custom garment sector. This printing process allows for seamless application of vivid designs onto various clothing materials, enabling small business owners to meet an array of customer demands efficiently. With a focus on ease of use and high-quality output, entrepreneurs can maximize their investment in DTF printing equipment to craft unique apparel that stands out in the competitive market. Understanding the techniques behind DTF transfers not only simplifies the production process but also positions you to create exceptional products that leave a lasting impression on your clientele. Join us as we delve deeper into the thriving world of DTF printing and explore how this innovative method can revolutionize your small business.

Understanding DTF Printing Technology

DTF printing technology has redefined the custom apparel industry, making it more accessible for small businesses. This innovative method involves a multi-step process that transfers high-quality ink from a specialized film to various fabric types. The key advantage of DTF printing is its ability to produce vibrant and detailed designs that can be applied to materials like cotton, polyester, and blends. This versatility allows business owners to cater to a wide range of customer preferences, from personalized t-shirts to unique sportswear.

Additionally, DTF transfers are considered more efficient than traditional methods like screen printing. With DTF, there is no need for extensive setup or multiple screens, reducing the time and effort needed to produce custom items. This technology not only supports rapid production but also helps maintain cost-effectiveness, making it an ideal solution for small business owners looking to thrive in the competitive custom apparel market.

Benefits of Using DTF Transfers for Small Businesses

One of the standout benefits of DTF transfers for small businesses is their economic viability. For startups, the initial investment in high-quality DTF printing equipment can be less daunting compared to other printing methods. Because DTF transfers require minimal setup, businesses can start production on smaller orders without incurring high costs typically associated with large screen printing batches. This allows entrepreneurs to experiment with their designs and adjust their inventory according to customer demand.

Moreover, the quality of the prints produced using DTF transfers is exceptional. The vibrancy and clarity of colors ensure that designs are accurately represented, which is crucial for customer satisfaction. Happy customers mean repeat business and recommendations, thereby increasing a small business’s brand visibility and sales potential. As a result, incorporating DTF transfers can lead to higher quality control, lower waste, and greater profitability in the long run.

Key Equipment Needed for DTF Printing

Starting your DTF printing journey requires specific equipment to ensure optimal results. The first essential item is a DTF printer capable of applying ink to heat transfer films. These printers are specifically designed to handle specialized inks that form a strong bond when heat pressed onto fabric. Investing in quality equipment is integral, as it lays the foundation for your printing business and dictates the overall quality of your output.

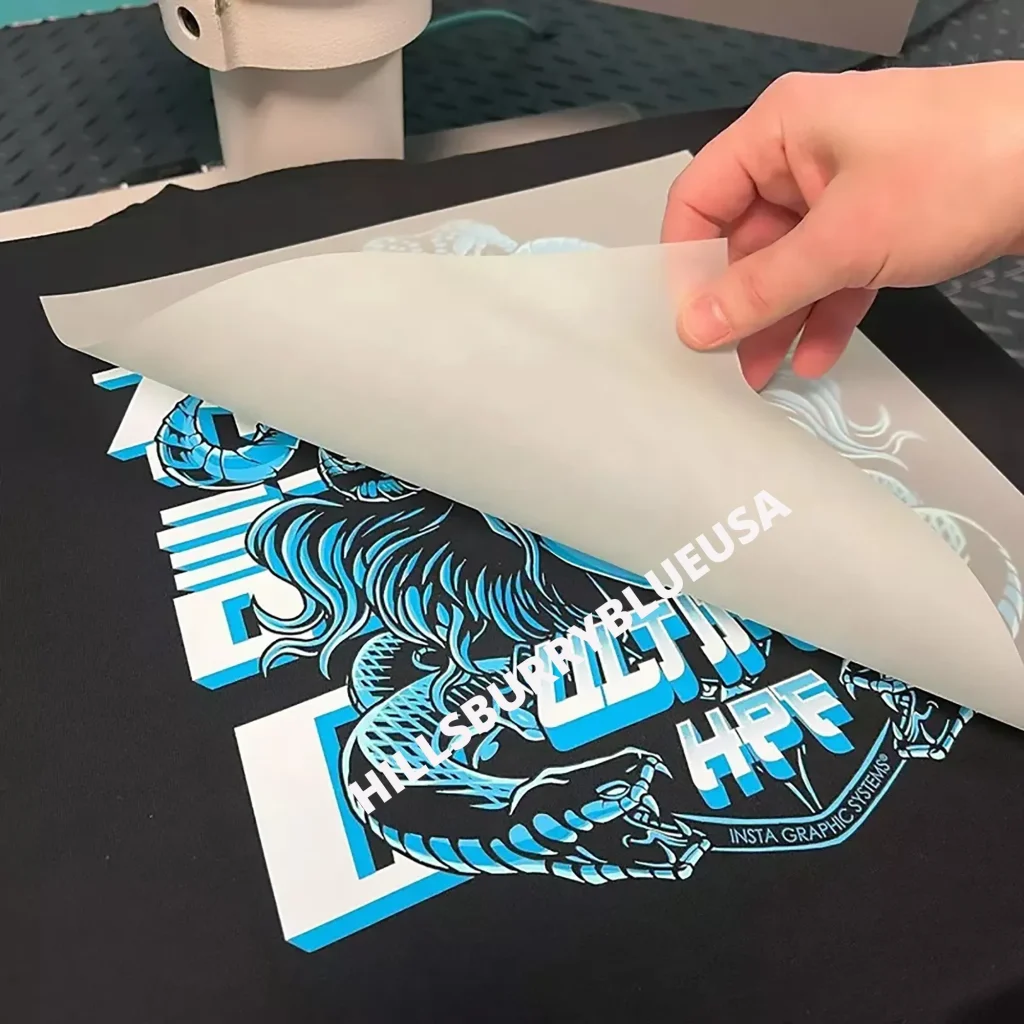

In addition to the DTF printer, you’ll need a reliable heat press that allows for precise control over temperature and pressure settings. This equipment is instrumental in transferring your designs effectively from film to fabric. It’s also important to select high-quality heat transfer films and compatible DTF inks and adhesives. The right materials will not only improve the durability and washability of your custom apparel but also enhance the color vibrancy of your prints.

How to Start Your DTF Printing Business

Starting a DTF printing business involves thorough planning and a clear understanding of your market. Initially, you should conduct extensive research to identify your target audience and niche within the custom apparel landscape. This insight will allow you to curate a unique range of products that address customer needs, setting your business apart from competitors. Once your market research is complete, you can outline a business plan that includes equipment purchasing and design production strategies.

After solidifying your business concept, invest in the necessary DTF printing equipment identified earlier. Quality matters—choose machines that are reliable and well-reviewed. Following this, focus on creating eye-catching designs. You can utilize graphic design software or collaborate with freelance designers to craft unique visuals that align with your brand identity. To reach your audience effectively, leverage digital marketing channels such as social media and e-commerce platforms, maximizing your exposure and customer engagement.

Marketing Strategies for DTF Printed Apparel

Marketing your DTF printed apparel effectively is vital to the success of your business. Start by establishing a strong online presence through social media platforms, interactive websites, and local marketplaces. Engaging content and visually appealing product presentations can capture the attention of potential customers, while targeted advertising campaigns can further enhance visibility. Offering promotions, such as discounts or free samples, will entice new customers to try your products.

Additionally, building relationships with local businesses can create collaborative opportunities for cross-promotion. Attending community events or trade shows can help you showcase your products and network with other entrepreneurs. Consider creating a referral program that rewards customers for sharing your business with their friends. This grassroots approach to marketing can significantly increase your customer base while fostering a sense of community around your brand.

Challenges and Solutions for DTF Printing Startups

As with any startup, entering the DTF printing industry comes with its challenges. One major hurdle is staying abreast of industry trends, as the fashion and printing landscapes are constantly evolving. To overcome this, entrepreneurs should engage with industry publications, participate in online forums, and attend workshops to remain informed about new techniques and customer preferences. Moreover, establishing a reliable supply chain is crucial for ensuring consistent product quality and minimizing disruptions in your workflow.

Managing startup costs can also pose a significant challenge for new business owners. Creating a detailed budget plan that designates funds towards essential equipment, materials, and marketing efforts can help maintain financial stability. Small business owners may also consider applying for grants or seeking funding options that cater specifically to creative ventures. By tackling these challenges head-on with strategic solutions, DTF printing startups can set themselves up for success.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, are a modern printing technique that allows vibrant designs to be transferred from a film onto various fabrics using a heat press. The ink is applied to a special heat transfer film and then adhered to the fabric, allowing for high-quality custom apparel printing.

What equipment do I need to start DTF printing for my small business?

To start DTF printing for your small business, you will need a DTF printer for applying ink to films, a heat press to transfer designs to fabric, heat transfer films, and DTF inks and adhesives which ensure durability and color vibrancy in your finished products.

What are the advantages of using DTF transfers for custom apparel?

DTF transfers offer several advantages for custom apparel, including versatility across different fabric types, cost-effectiveness for small orders, ease of use, and the ability to produce high-quality prints with vibrant colors and detailed designs.

How can I ensure quality prints when using DTF transfers?

To ensure quality prints with DTF transfers, perform thorough testing of your printing process, maintain your equipment well, use high-quality materials, and implement quality control measures to prevent common printing mistakes before launching your products.

What is the cost comparison of DTF printing versus other printing methods?

DTF printing is generally more cost-effective compared to traditional methods like screen printing, especially for smaller orders. The initial investment in DTF printing equipment is often offset by lower operational costs, making it a viable option for small businesses.

How do I start my own DTF printing business?

To start your own DTF printing business, research your market to identify your target audience, invest in high-quality DTF printing equipment, design unique graphics, and implement marketing strategies such as social media promotions and local events to attract customers.

| Key Point | Description |

|---|---|

| What is DTF Printing? | DTF printing transfers ink from a film to fabric using a DTF printer and heat press, allowing for vibrant designs on various fabrics. |

| Benefits of DTF Transfers | Versatile across fabrics, cost-effective, easy to use, and produces high-quality prints. |

| Essential Equipment | Includes a DTF printer, heat press, heat transfer film, inks, and adhesives. |

| Steps to Start Your DTF Printing Business | 1. Research your market 2. Purchase equipment 3. Design production 4. Marketing your business 5. Quality control |

| Challenges and Considerations | Keeping up with trends, securing reliable supplies, and managing startup costs are key challenges. |

Summary

DTF Transfers are redefining custom apparel printing for small businesses, allowing entrepreneurs to provide high-quality, vibrant prints on various fabrics at a cost-effective rate. With the simplicity of the DTF printing process, small business owners can quickly learn and adapt, enabling them to enter the market with confidence. Coupled with strategic marketing and a deep understanding of industry trends, embarking on the DTF transfer journey can lead to significant entrepreneurial success.