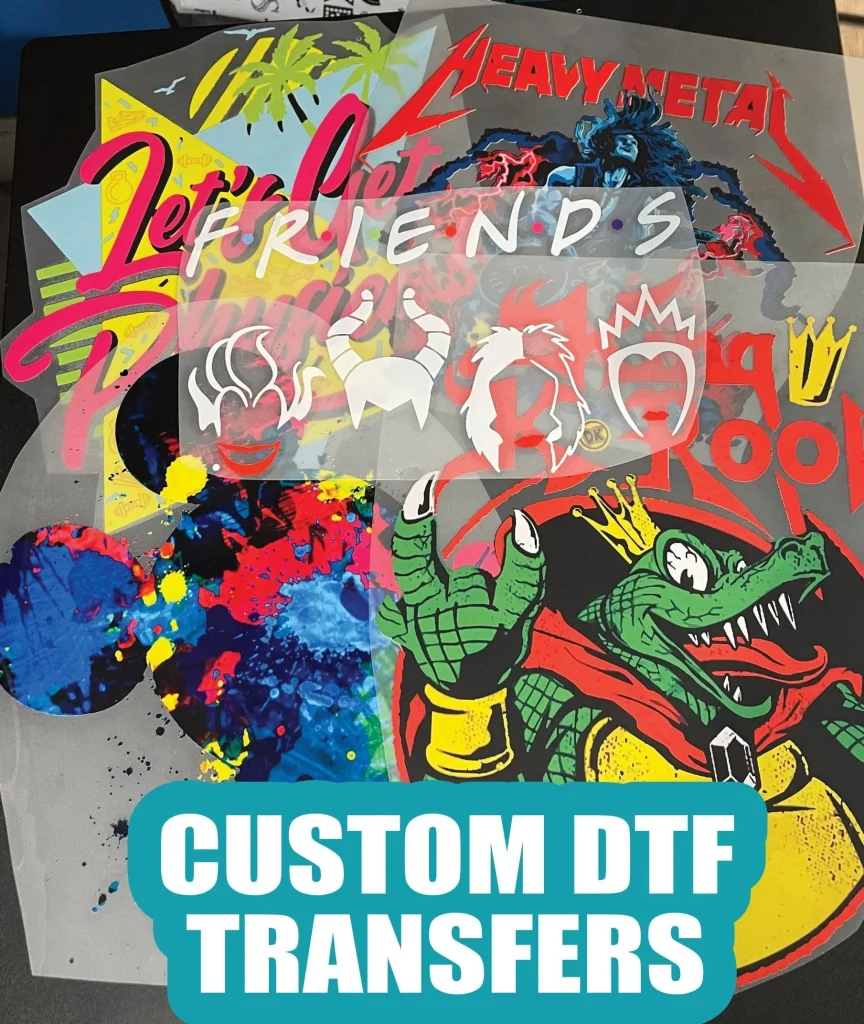

DTF transfers, also known as Direct-to-Film transfers, are revolutionizing the garment printing industry with their ability to produce stunning, high-quality designs that are both versatile and durable. As more businesses discover the unmatched benefits of DTF printing, the demand for the best DTF transfers is surging, placing them at the forefront of modern printing techniques. This innovative method not only ensures vibrant colors but also allows for detailed designs on a wide range of fabrics including cotton, polyester, and their blends. Additionally, sustainability in DTF is becoming increasingly important, appealing to eco-conscious consumers who are keen on reducing waste in textile production. By harnessing the strengths of DTF technology, brands can enhance their offerings while contributing to a more sustainable future in the garment printing sector.

Exploring the world of Direct-to-Film transfers, it’s essential to understand how this cutting-edge technique is reshaping the landscape of garment decoration. Often referred to as DTF printing, this method empowers designers and businesses to create breathtaking prints that appeal to diverse consumer tastes. With its capability to print on various materials and its eco-friendly attributes, DTF technology stands out as an optimal choice for garment production. By leveraging the advantages of DTF transfers, entrepreneurs can capitalize on trends while delivering high-quality products that resonate with today’s market demands. This guide will delve into the myriad benefits and practical applications of this innovative printing method, setting the stage for a deeper understanding of its transformative impact.

The Basics of DTF Transfers and Their Technology

DTF transfers, or Direct-to-Film transfers, utilize advanced technology to revolutionize the garment printing industry. This method involves printing designs onto a specialized film, which is later transferred to fabric using heat and pressure. The films are coated with a unique adhesive that bonds with a variety of fabrics, making DTF printing not only versatile but also engaging for designers looking to create intricate and colorful designs. This innovative approach to printing combines simplicity with impressive outcomes, catering to both small businesses and larger commercial entities.

The printing process begins with a quality DTF printer that uses specialized inks compatible with the transfer films. After printing the design, a powder adhesive is applied to the printed film. The curing stage, which involves using a heat press, ensures that the adhesive sticks to the fabric as intended. This comprehensive understanding of DTF technology allows creators to harness its capabilities for producing unique, standout garments that reflect current trends in fashion and design.

Benefits of Using DTF Transfers in Garment Printing

One of the primary advantages of DTF transfers is their exceptional durability. Unlike traditional printing methods that may fade over time, DTF prints remain vibrant and intact even after multiple washes. This durability is a significant selling point for businesses looking to produce high-quality apparel that stands the test of time. The technology behind DTF transfers also eliminates the issues of weeding, commonly faced in vinyl cutting, enabling faster production times and more efficient processes.

Furthermore, DTF printing excels in versatility, making it suitable for varied fabric types, from cotton to blends and even synthetic materials. This adaptability allows businesses to cater to a broader audience, offering custom designs for varying preferences and styles. With the ability to print on both light and dark fabrics, DTF transfers truly empower designers to unleash their creativity without limitations.

Sustainability in DTF Printing: A Greener Approach

The garment industry has faced scrutiny regarding its environmental impact, leading many businesses to seek sustainable practices. DTF transfers present a more eco-friendly option compared to traditional methods, primarily by reducing waste. The precise application of ink minimizes excess usage and limits material scraps, addressing one of the major concerns in textile production. As eco-conscious consumers become more prevalent, DTF printing aligns perfectly with the rising demand for sustainably-produced clothing.

Investing in DTF technology not only reduces waste but also supports a greener future for garment printing. Companies that engage in sustainable practices can enhance their brand image while appealing to customers who prioritize environmental responsibility in their purchasing decisions. This shift towards eco-friendliness in the DTF landscape reflects a broader trend in the industry, where conscious choices are progressively recognized as crucial business strategies.

Where to Source the Best DTF Transfers

Finding high-quality DTF transfers is essential for achieving the best results in your garment projects. The market is flooded with various suppliers; however, it’s paramount to choose those that are reputable and provide a wide range of designs and customization options. To ensure top-notch DTF transfers, look for suppliers that prioritize material quality and deliver products with vibrant colors and excellent adhesion properties.

Customer reviews can be a useful tool in evaluating suppliers. Positive testimonials indicating strong customer service and product reliability are signs of trustworthy partners in your DTF journey. Additionally, consider suppliers that offer unique design options that align with your brand’s identity; this not only enriches your offerings but also strengthens consumer allegiance.

Best Practices for Applying DTF Transfers

Using DTF transfers effectively involves precise and methodical steps. Start by selecting a design that resonates with your target audience; this is crucial for making a lasting impression. Once a design has been finalized, employ a DTF printer to accurately print it onto the film. Ensuring your printer settings are calibrated correctly will facilitate vibrant and detailed output.

After printing, the application of the adhesive powder is crucial. Evenly sprinkling the powder and properly curing it ensures that the transfer adheres well to the fabric during the heat press stage. Additionally, customization of time and temperature settings according to fabric type leads to the best adhesion results, allowing the DTF transfers to maintain their quality and integrity through subsequent washes.

Innovations and Trends in DTF Services

The DTF printing industry is experiencing rapid innovation, with new approaches being introduced to enhance the user experience and streamline services. Platforms like Snuggle have developed web-to-print solutions that revolutionize how businesses interact with DTF services, allowing easier access to printing technology and customization features. Such efforts not only optimize productivity but also cater to the evolving needs of designers and entrepreneurs striving for success in a competitive market.

These innovations in DTF services reflect a commitment to progress within the garment printing sector. With constant advancements, companies can provide enhanced offerings that resonate with the changing dynamics of consumer preferences and industry standards. This adaptability is crucial for sustaining growth and remaining relevant in a constantly evolving landscape.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are an innovative garment printing technology that allows for designs to be printed on a special film and then transferred to fabric. The process involves printing an image on the film, applying a powder adhesive, and curing it with a heat press. This method produces vibrant, durable prints on various fabric types, including cotton and polyester.

What are the main advantages of using DTF Transfers in garment printing?

The best DTF transfers offer several advantages, including exceptional durability, versatility across different fabric types, and eco-friendliness due to reduced waste in the printing process. DTF printing ensures that the colors remain vivid and intact even after multiple washes, making it ideal for fashion brands aiming for high-quality results.

Where can I find quality DTF transfers for my printing needs?

To find high-quality DTF transfers, look for trusted suppliers that specialize in Direct-to-Film transfers. Check reviews and ratings to ensure the quality of their products, and consider suppliers that offer customization options to meet your specific garment printing needs.

How can I effectively use DTF Transfers in my garment printing projects?

Using DTF transfers effectively involves a few key steps: select an appealing design, print it onto a special transfer film, apply the adhesive powder, and use a heat press to transfer the design onto your fabric. Proper attention to temperature and timing is essential to ensure a successful transfer that lasts.

Is it possible to remove DTF Transfers once they are applied?

Removing DTF transfers can be complex and risky, as it may damage the garment. If removal is necessary, it’s advisable to use fabric-safe solvents and to test the removal on an inconspicuous area first. Always approach removal carefully to avoid harming the fabric.

What impact does sustainability have on DTF Transfers in the garment printing industry?

Sustainability in DTF transfers is significant as this printing method produces less waste compared to traditional techniques. DTF technology minimizes excess materials and inks, appealing to eco-conscious consumers while still delivering high-quality garment printing options. This eco-friendly aspect makes DTF transfers a preferred choice for brands focused on sustainable practices.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | DTF (Direct-to-Film) transfers are a printing technique that utilizes special films to print designs that can be transferred onto various fabrics. |

| Advantages | 1. **Durability**: Prints resist fading, ideal for frequent washing. 2. **Versatility**: Adheres to multiple fabric types including different colors. 3. **Eco-Friendliness**: Reduces waste and excess materials compared to traditional methods. |

| How to Use DTF Transfers | 1. Select the design. 2. Print on special transfer film. 3. Apply adhesive powder. 4. Use heat press to transfer. 5. Cool and carefully remove film. |

| Where to Buy DTF Transfers | Look for reputable suppliers, check material quality, read reviews, and consider customization options. |

| Removing DTF Transfers | Removing DTF transfers can damage fabric; use fabric-safe solvents and test on inconspicuous areas first. |

| Innovations | Companies are innovating in DTF services; for instance, Snuggle DTF launched a web-to-print platform. |

Summary

DTF Transfers are revolutionizing the garment printing landscape, offering businesses unbeatable durability, versatility, and eco-friendliness. This technology allows for rich, vibrant designs to be printed on diverse fabrics seamlessly, enhancing product quality while promoting sustainability. As the demand for custom apparel continues to rise, mastering the unique characteristics and applications of DTF Transfers will set your brand apart in the competitive textile market. The continuous advancements in DTF technology further ensure that it remains a vital resource for creators looking to maximize their design potential and operational efficiency.