In the ever-evolving field of fabric printing, **DTF transfers** have emerged as a groundbreaking method that redefines how designs are applied to textiles. This Direct-to-Film printing process allows for the seamless transfer of vivid graphics onto a variety of fabric substrates, making it a favored choice among custom apparel creators. By leveraging advanced technology, DTF gives artists and businesses the ability to produce intricate designs with remarkable color accuracy and detail. As we navigate through the nuances of the DTF transfer process in this blog, you’ll uncover everything from the initial design stages to the final print application, all while exploring the numerous benefits this method brings to the table. Get ready to transform your fabric printing projects with the innovative capabilities of DTF.

In recent years, the world of fabric decoration has witnessed the rise of Direct-to-Film printing techniques, also known as DTF transfers. This novel approach combines efficiency and quality, allowing intricate designs to be seamlessly applied to various textile materials, including cotton and polyester. By utilizing a specialized printing process, artists and businesses can achieve high-quality results with impressive longevity and washability. As we delve deeper into this fascinating topic, we’ll also explore alternative methods for applying designs to fabrics, revealing the strengths and advantages that make DTF an increasingly popular choice for custom apparel.

Understanding DTF Printing Technology

Direct-to-Film (DTF) printing technology is a modern method that bridges digital printing with fabric applications. This method allows intricate designs and graphics to be transferred with high fidelity onto textiles, making it suitable for a variety of items such as t-shirts, hoodies, and tote bags. DTF prints are known for their vibrant colors and sharp detail, providing designers and businesses with excellent results that cater to a growing demand for personalized and unique apparel.

The underlying technology involves printing on a special PET film which serves as the medium for the design before it is transferred to the final fabric. As DTF technology evolves, enhancements in printer capabilities and ink formulations are leading to improvements in color vibrancy and material compatibility. As a result, DTF transfers are becoming a go-to solution for custom apparel makers and hobbyists alike.

The Step-by-Step DTF Transfer Process

The DTF transfer process can be broken down into five core stages, starting with the design creation. This initial phase requires the use of graphic design software to ensure that high-resolution images are produced. This attention to detail is crucial, as it dictates the overall quality of the print. Following design, the printing phase involves using a DTF printer to apply the chosen design onto PET film. This stage is where modern advancements in printer technology truly shine, allowing for rapid processing speeds and exceptional color accuracy.

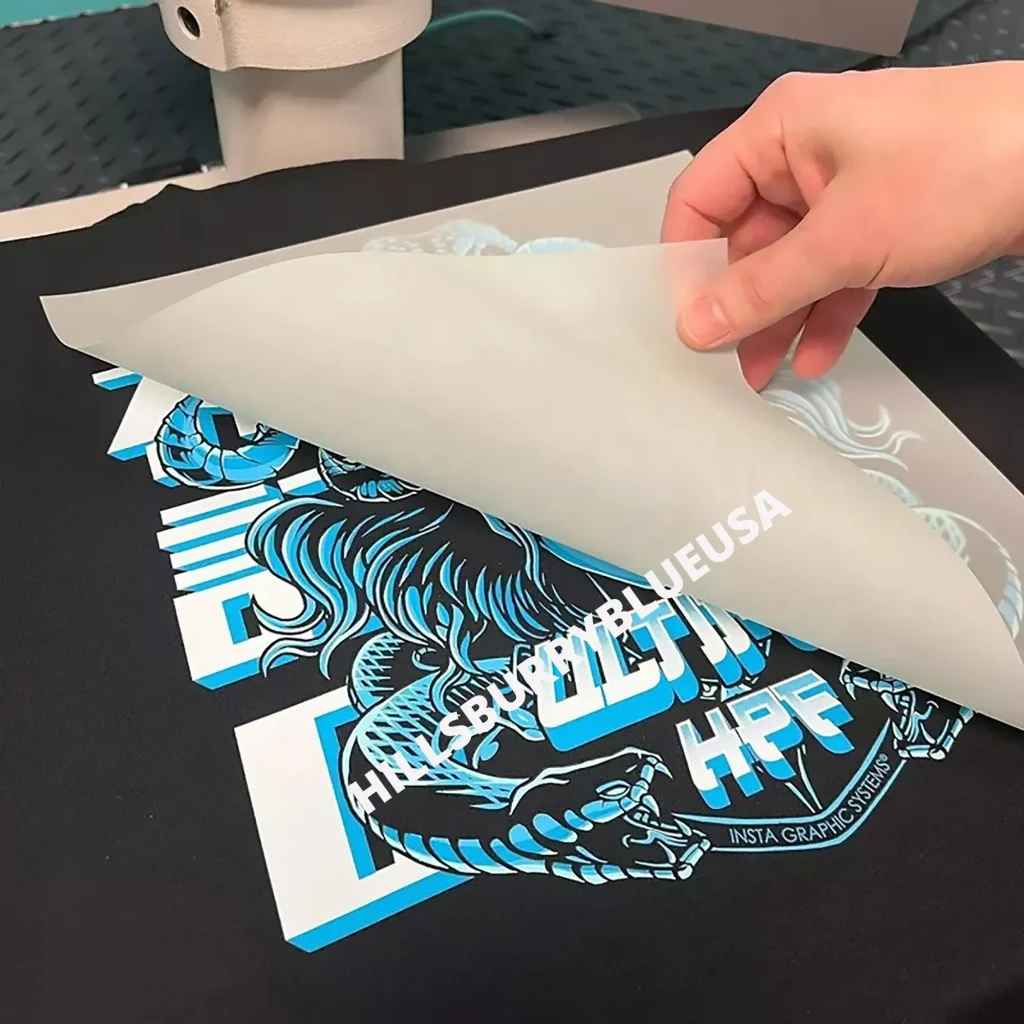

After printing, the next crucial step is the application of hot melt powder to the wet ink. This creates a bond essential for the transfer process. The film is then heat-pressed onto the selected fabric, solidifying the design as the heat activates the powder. The post-pressing stage includes carefully peeling off the film, whether hot or cold, which significantly influences the print’s final appearance and durability. Designers and manufacturers have to navigate these stages skillfully to ensure high-quality outcomes.

The Versatility of DTF Transfers in Fabric Printing

One of the most appealing aspects of DTF transfers is their versatility. This method can be applied to a wide range of materials, including cotton, polyester, and blends. As a result, it opens up numerous opportunities for custom apparel, allowing for a variety of products that can incorporate vibrant designs. Whether it’s fashion, sportswear, or promotional items, DTF printing meets diverse needs and preferences in the fabric printing industry.

Additionally, DTF transfers are effective for both large scale productions and small runs, including personalized orders. This flexibility makes DTF an ideal option for different types of businesses—from startup apparel lines to established fashion brands—looking to provide tailored products without the steep costs associated with traditional printing methods.

Cost-Effectiveness of DTF Printing

In comparison to conventional fabric printing methods, DTF printing offers cost advantages that are hard to ignore. The elimination of screens and setup fees allows businesses to produce custom designs affordably, especially for small batches. This is particularly beneficial for entrepreneurs and companies wanting to test new ideas without overcommitting financially.

Furthermore, the efficiency of the DTF process minimizes waste materials and reduces production costs in the long run. As technological advancements continue to drive down prices and increase accessibility, many small businesses are finding DTF transfers to be a budget-friendly option for entering the custom apparel market.

Durability and Quality of DTF Transfers

Durability is a key factor in fabric printing, and DTF transfers have a strong reputation for producing long-lasting, wash-resistant prints. The combination of high-quality materials and advanced printing techniques results in designs that maintain their vibrancy and integrity even after multiple washes. This is a significant advantage for apparel that is frequently worn and laundered.

Moreover, ongoing improvements in DTF technology are enhancing the longevity of prints, with manufacturers exploring new inks and materials that further strengthen washability and durability. The result is a product that not only looks good on the shelf but also performs well in everyday use, making it a trustworthy choice for custom apparel.

Recent Trends in DTF Printing Technology

The landscape of DTF printing is undergoing rapid transformation, driven by increasing consumer demand for custom apparel. The market is witnessing a notable surge as more brands recognize the value of personalization for their products. With the rise of online custom t-shirt shops and direct-to-consumer models, the DTF transfer process is becoming more widespread and adopted among businesses seeking a competitive edge.

Additionally, advancements in sustainability are reshaping DTF technology as manufacturers are focusing on environmentally friendly inks and methods. Water-based inks, for instance, are becoming increasingly popular due to their lower environmental impact, aligning with consumer preferences for more sustainable production practices. As these trends continue, DTF printing is set to gain further momentum in the fabric printing industry.

Frequently Asked Questions

What is the DTF transfer process and how does it work?

The DTF transfer process involves several stages starting with design creation using graphic design software. Next, the design is printed on PET film with a DTF printer. After printing, hot melt powder is applied to bond with the ink. The film is then heat transferred onto the fabric, effectively melding the ink with the material’s fibers. Finally, the film is peeled away to reveal the printed design. This method is favored for its quality and durability in fabric printing.

Why should I choose DTF printing over other fabric printing methods?

Choosing DTF printing offers numerous advantages, including versatility as it can be applied to various materials such as cotton and polyester. Additionally, it is cost-effective for small orders since it eliminates the need for screens and setup fees. DTF transfers are also recognized for their durability and resistance to cracking, making them a reliable option for custom apparel.

What types of fabrics are ideal for DTF transfers?

DTF transfers work well on a range of fabrics, including 100% cotton, polyester, and cotton-poly blends. This versatility allows you to create custom apparel across different textile types, ensuring vibrant and durable prints regardless of the fabric choice.

How does the quality of DTF transfers compare to traditional printing methods?

DTF transfers often surpass traditional printing methods by offering high-resolution, vibrant colors and fine details with less waste. The technology behind DTF printing allows for greater accuracy and speed, resulting in superior fabric prints that maintain quality after multiple washes.

Are DTF transfers environmentally friendly?

Yes, recent advancements in DTF transfer technology have focused on sustainability. Many DTF printers now utilize water-based inks that reduce environmental impact compared to solvent-based alternatives. This shift towards eco-friendliness makes DTF printing a more responsible choice for custom apparel production.

What advancements are being made in DTF printing technology?

Recent developments in DTF printing include improved powder application techniques that enhance efficiency and print quality. The market for DTF transfers is also expanding as demand for custom apparel grows. Manufacturers are continuously innovating to incorporate sustainable practices and materials, ensuring DTF remains a competitive option in the fabric printing industry.

| Key Point | Details |

|---|---|

| Introduction | DTF Transfers is an innovative fabric printing method that allows for high-quality and vibrant designs. |

| Definition of DTF Transfers | A method using advanced technology to transfer intricate graphics onto textiles, known for vivid colors and reduced waste. |

| Process Stages | 1. Design Creation 2. Printing on PET Film 3. Powder Application 4. Heat Transfer 5. Peeling the Film |

| Benefits of DTF Transfers | Versatile, cost-effective, and durable; suitable for various materials and small production runs. |

| Recent Developments | Growing market demand for custom apparel and enhanced sustainability practices in DTF technology. |

| Resources | Helpful links for further reading: Printful’s Blog, ResearchGate, Printing Impressions, Screen Printing Magazine. |

Summary

DTF transfers are revolutionizing the fabric printing landscape by offering a versatile and efficient means to create high-quality designs on various textiles. This innovative printing method not only emphasizes vibrant colors and detailed graphics but also focuses on sustainability and cost-effectiveness, making it an appealing choice for custom apparel enthusiasts. As the technology continues to advance, staying informed about the latest developments in DTF transfers will empower businesses and creators alike to thrive in an ever-evolving market.