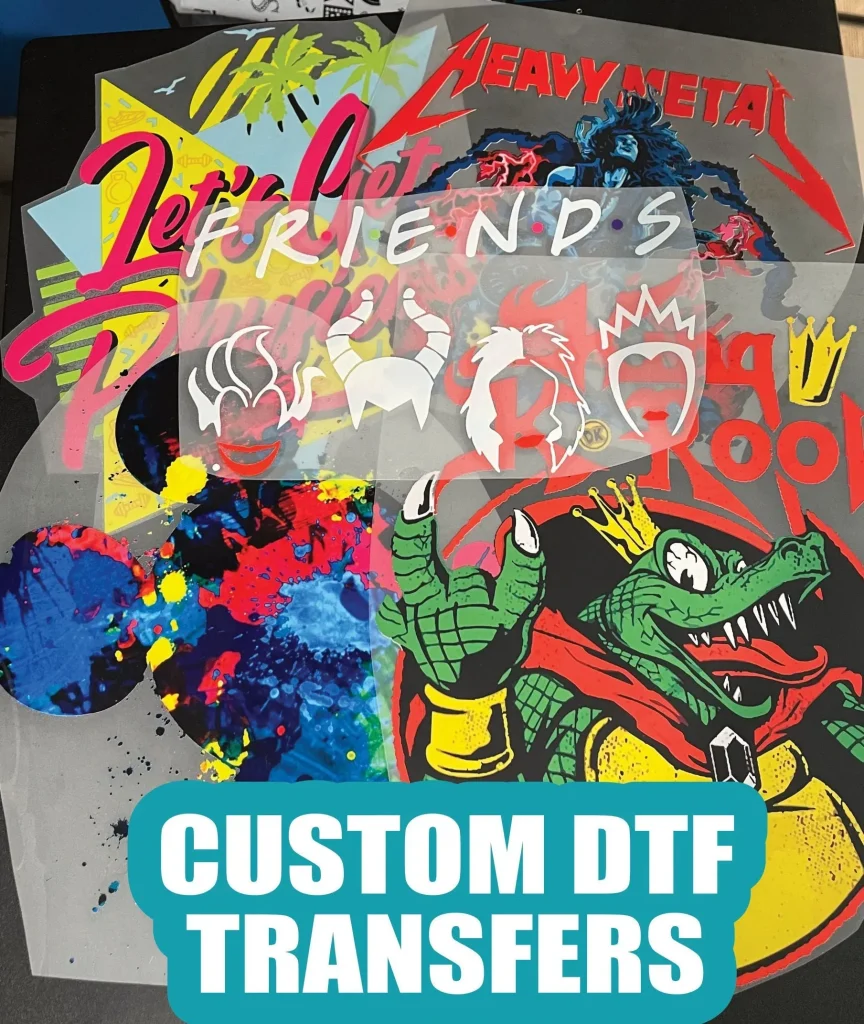

DTF transfers, or Direct-to-Film printing, represent a groundbreaking advancement in the world of custom apparel printing, seamlessly combining quality with efficiency. This innovative method allows designers to create vibrant and detailed prints on a variety of fabrics, catering to both individual and commercial needs. By using DTF printing techniques, businesses can tap into the abundant benefits of DTF, such as exceptional versatility and impressive durability of the prints. This guide will explore DTF printing methods and how they can streamline your printing processes, maximizing both productivity and creativity. Join us as we delve into the essentials of DTF transfers and discover how they can elevate your custom designs.

Known in the industry as Direct-to-Film (DTF) printing, this novel technique offers versatile solutions for fabric decoration and design. By adopting DTF transfer techniques, businesses can ensure the production of striking graphic elements that resonate with consumers’ demands for high-quality, personalized apparel. This guide will elucidate the advantages and methods associated with DTF printing and its role in modern custom clothing production. Explore the landscape of custom apparel printing where DTF simplifies the process and enhances creativity, paving the way for impactful garment designs. As we navigate through various aspects of DTF, the potential to revolutionize your printing experience will become abundantly clear.

Understanding Direct-to-Film (DTF) Printing

Direct-to-Film (DTF) printing is revolutionizing the custom apparel landscape, offering a new methodology for achieving vibrant and durable prints. Unlike traditional printing techniques, DTF printing utilizes a unique process whereby designs are printed directly onto a specialized film, which is then transferred onto fabric. This approach not only enhances the design’s clarity and color vibrancy but also allows the method to be applied to a variety of materials, including cotton, polyester, and even silk blends. As the demand for personalization in fashion grows, understanding DTF printing becomes crucial for businesses aiming to stay competitive in the market.

The process begins by printing artwork onto DTF film using high-quality water-based inks, ensuring the designs are environmentally friendly as well. Once printed, the film is treated with an adhesive powder, which is cured with heat, providing a strong bond between the film and fabric. This method proves to be advantageous for businesses, as they can achieve high-quality prints even on dark fabrics, something that many other printing methods struggle to accomplish. Overall, DTF printing opens up a wealth of possibilities for creative customization, making it a versatile choice for apparel companies.

Exploring the Benefits of DTF Transfers

DTF transfers are becoming increasingly popular due to their extensive benefits that cater to various business needs. One of the standout features of DTF printing is its versatility. DTF transfers can be successfully applied to multiple fabric types, making it an exceptional option for creating diverse and tailored apparel. This method allows for striking designs to be printed on everything from basic cotton tees to polyester athletic wear, enhancing the opportunities for personalized and custom apparel offerings. Beyond versatility, the durability of DTF prints surpasses many traditional printing methods, ensuring that designs remain vibrant and intact even after numerous washes.

Moreover, DTF transfers prove to be a cost-effective solution for small runs and limited edition prints. The DTF printing process negates the need for extensive setup times and material waste, allowing small businesses and hobbyists to produce single and small batches without financial strain. This economic advantage, combined with the ability to produce vivid and detailed artwork, places DTF transfers at the forefront of custom printing techniques. In summary, the benefits of DTF transfers not only enhance the quality of printed products but also streamline the production process for businesses of all sizes.

Latest Innovations in DTF Printing Technology

The landscape of DTF printing technology is rapidly evolving, with recent innovations paving the way for enhanced productivity and quality in custom apparel printing. Manufacturers are increasingly introducing advanced printer models specifically designed for DTF applications, featuring cutting-edge technology that facilitates faster printing speeds and higher resolutions. These advancements cater to the growing market demand, allowing businesses, regardless of size, to leverage DTF printing techniques effectively. Additionally, the development of more affordable, high-quality water-based inks has made DTF printing accessible to a broader audience, further encouraging small businesses to invest in this technology.

Recent enhancements also include improved adhesive powders that play a crucial role in the bonding process of DTF printing. The availability of a variety of adhesive options enables printers to select the perfect adhesive that aligns with the fabric and desired print durability. As the DTF printing market continues to grow, adapting to these innovations can drastically improve the overall efficiency and quality of custom apparel production. Businesses that stay updated with the latest developments in DTF technology will undoubtedly enhance their competitive edge in the ever-evolving fashion landscape.

Effective DTF Transfer Techniques for Successful Printing

Utilizing effective DTF transfer techniques is essential for achieving successful results in custom apparel printing. One of the key techniques involves the use of high-quality heat press machines that are essential for applying the DTF films to various fabrics. Modern heat presses can be programmed with precise adjustments for time, temperature, and pressure, optimizing the transfer process. It’s vital to understand and calibrate these settings based on the specific fabric type and the DTF film used, as proper application significantly determines print quality and durability.

Another critical aspect of DTF transfer techniques is the careful management of adhesive powders during the transfer process. The powder must be evenly sprinkled over the printed film to ensure a robust bond between the ink and the fabric. Inconsistent application can lead to peeling or fading of the design. Thus, mastering the technique of using adhesive powders empowers businesses to produce long-lasting and vibrant prints. By adhering to these transfer techniques, printers can ensure that their DTF applications consistently achieve high standards, enhancing customer satisfaction and sustaining business growth.

Best Practices to Optimize DTF Printing Outcomes

Implementing best practices in DTF printing can significantly uplift the quality of printed products and overall efficiency of the printing process. One fundamental practice is investing in quality machinery, particularly printers that are designed specifically for DTF applications. A good-quality printer yields high-resolution images and ensures accurate color reproduction, which are critical for client satisfaction. Additionally, sourcing quality transfer films cannot be overstated; the film’s type greatly influences the final product’s durability and appearance.

Incorporating a pre-treatment process is another best practice that enhances ink adhesion. Pre-treating fabric ensures a better bond, improving the longevity of the prints. Furthermore, it’s advisable to establish a routine maintenance schedule for printing equipment to prevent any potential issues that could arise due to wear and tear. By following these best practices, businesses can optimize their DTF printing processes, resulting in beautiful, long-lasting, and customer-attracting apparel.

Addressing Challenges in DTF Printing

While DTF printing offers numerous advantages, it is essential to be aware of the challenges that can arise during the process. One common challenge is managing ink costs, as the expense can accumulate quickly, especially when producing large batches. However, by researching and selecting more affordable ink options without compromising quality, businesses can mitigate these costs and maintain profitability. Additionally, implementing an efficient inventory management system can help track and optimize ink usage over time.

Maintaining equipment is another critical challenge faced by those in DTF printing. Regular maintenance can be labor-intensive, but it is necessary to ensure that printers and heat presses are operating at peak performance. It’s advisable to develop a maintenance checklist that includes cleaning the printers, inspecting components, and addressing any wear and tear promptly. Furthermore, ensuring consistent print quality is paramount. Establishing standard operating procedures that include guidelines for temperature settings, pressure adjustments, and transfer timing can aid in achieving consistency and reliability in final products.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a specialized film using water-based inks, which are then layered with adhesive powder. This film is heated and pressed onto the target fabric, allowing for vibrant and detailed prints on various materials. This DTF printing method is gaining traction for its efficiency and high-quality results.

What are the benefits of DTF printing for custom apparel?

The benefits of DTF printing for custom apparel include versatility to print on different fabrics, vivid color reproduction for detailed designs, and impressive durability that withstands multiple washes. Additionally, DTF transfers are cost-effective for small runs, making them ideal for personalized apparel without the high setup costs associated with other printing methods.

What are some popular methods used for applying DTF transfers?

Popular methods for applying DTF transfers include using heat press machines that provide the necessary heat and pressure for the transfer process, and employing adhesive powders to bond the ink to the film and fabric securely. Mastering these DTF transfer techniques ensures optimal application and quality of the final garment.

How does DTF printing compare to traditional printing methods?

DTF printing stands out from traditional printing methods such as screen printing by offering more flexibility for small runs and diverse fabric applications. While screen printing can be costly and time-consuming for custom orders, DTF transfers allow for quick setups with high-quality, durable prints, making it a preferred choice for custom apparel printing.

What challenges should I be aware of when using DTF transfers?

Challenges in DTF printing include managing ink costs, which could rise for larger batches, and the need for regular equipment maintenance to ensure consistent print quality. Additionally, tight specifications for heat and temperature during the transfer process can affect the final output, necessitating careful monitoring.

What factors should I consider when selecting DTF transfer supplies?

When selecting supplies for DTF transfers, prioritize high-quality printers designed specifically for DTF applications, reliable transfer films that enhance print quality, and suitable adhesive powders for optimal bonding to fabrics. Implementing a pre-treatment process on fabrics can also significantly improve adhesion and the longevity of prints.

| Key Points | Details |

|---|---|

| What is DTF Printing? | DTF printing involves printing designs onto a specialized film, which is then applied to fabrics using heat and pressure. |

| Benefits of DTF Transfers | 1. Versatility: Works on various fabrics (cotton, polyester, etc.) 2. Vivid Colors: High-quality, colorful graphics. 3. Durability: Long-lasting prints with good wash resistance. 4. Economical: Cost-effective for small production runs. |

| Recent Developments | 1. Improved Printer Models: New printers enhance efficiency and print quality. 2. Affordable Inks: Cost-effective options lead to quality prints. 3. Market Growth: Rising demand for personalization in clothing and accessories. |

| Popular DTF Transfer Methods | 1. Heat Press Machines: Essential for applying DTF films. 2. Adhesive Powders: Crucial for binding ink to fabric. |

| Best Practices | 1. Invest in Quality Machinery: Essential for quality prints. 2. Select Quality Transfer Film: Impacts durability and quality. 3. Implement a Pre-treatment Process: Enhances ink adhesion. |

| Challenges | 1. Management of Ink Costs: Can accumulate for large batches. 2. Equipment Maintenance: Requires regular attention. 3. Print Quality Assurance: Consistency can be challenging. |

Summary

DTF Transfers are revolutionizing the printing industry, offering flexible solutions for custom apparel creation. This innovative technique not only allows for vivid colors and durable prints but also serves diverse fabric types, making it a versatile choice for businesses of all sizes. As technology advances, the benefits of DTF transfers become even more pronounced, paving the way for unique designs and personalized products. By embracing the best practices discussed in this guide, businesses can leverage DTF transfers to elevate their offerings, optimize production costs, and enhance customer satisfaction, thus marking a significant milestone in their printing journey.