DTF transfers, or Direct-to-Film transfers, are revolutionizing the garment decoration landscape by presenting a modern alternative to traditional printing methods like screen printing. Utilizing cutting-edge DTF printing technology, this method allows for exceptional detail and vibrancy in designs applied to fabrics. Unlike conventional methods, which can be labor-intensive and often lead to increased waste, DTF printing is more efficient and aligns with the demand for sustainability in printing. As the industry shifts towards eco-friendly printing solutions, DTF transfers stand out as a beacon of innovation, marrying quality and responsibility. With the fabric of the printing world being woven with advances in technology, understanding DTF transfers and their benefits is essential for anyone in the field.

Direct-to-Film transfers, also referred to as DTF prints, signify a breakthrough in the realm of fabric decoration, emerging as a stylish and effective option compared to conventional techniques. This innovative method employs modern printing technology to achieve outstanding detail and color saturation, setting it apart from traditional ink methods. The shift towards DTF printing is largely driven by an increased emphasis on sustainability, as it minimizes waste while offering vibrant results that are both appealing and durable. In a market where the demand for eco-conscious solutions continues to rise, DTF printing aligns perfectly with the trends in eco-friendly printing practices, showing promising potential for future advancements in printing technology. By recognizing the various terms associated with DTF, designers and businesses alike can better navigate the opportunities this printing innovation presents.

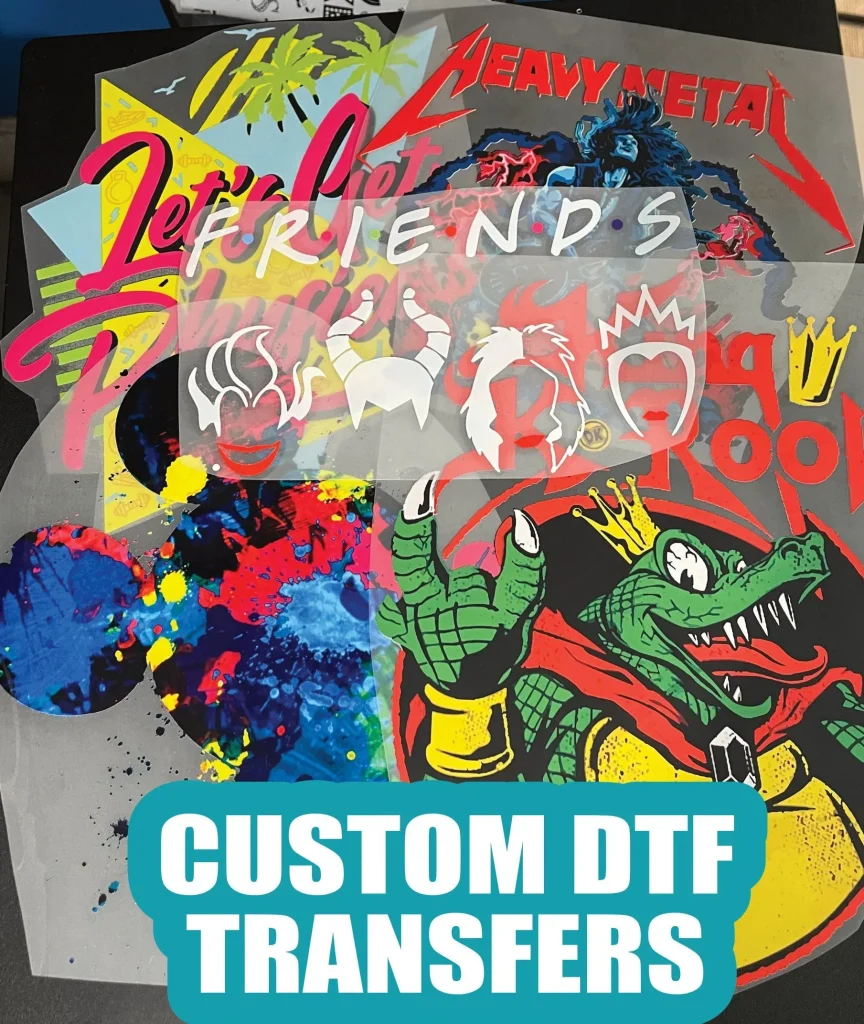

Understanding DTF Transfers: A Modern Solution

Direct-to-Film (DTF) transfers represent a significant leap forward in printing technology, employing a digital process that allows for intricate designs to be printed directly onto a film. This film is then transferred to fabric using heat and pressure, resulting in stunningly vibrant images with unparalleled detail. In comparison to traditional methods such as screen printing, DTF offers a streamlined approach that eliminates many labor-intensive stages, allowing for quicker turnarounds and a more efficient use of materials.

One of the hallmarks of DTF printing is its flexibility in design. Unlike screen printing, where creating complex multicolor prints can be challenging due to the limitations of the medium, DTF can handle a wide spectrum of colors and intricate patterns with ease. This adaptability has captured the attention of both professional apparel decorators and DIY enthusiasts, as it opens the door to new creative possibilities without requiring advanced technical skills.

Sustainability and Environmental Impact of DTF Transfers

Sustainability in printing is more important now than ever, and DTF transfers are at the forefront of this movement. With a significant reduction in material waste thanks to precise ink application, DTF technology minimizes excess usage that is often seen in traditional printing methods. This eco-friendly approach reduces not only the environmental footprint of the printing process but also aligns with the growing consumer demand for sustainable practices in the fashion and textile industry.

Moreover, the use of specialized inks designed for DTF printing contributes to lower environmental impact. These inks are formulated to adhere effectively to fabrics without the need for additional chemicals or processes that could harm the environment. Brands adopting DTF technology showcase their commitment to sustainability, appealing to a demographic that increasingly prioritizes eco-conscious choices in their purchasing patterns.

Technological Innovations in DTF Printing

The rapid advancement of printing technology has greatly influenced the evolution of DTF transfers, leading to enhanced product quality and user experience. Recent innovations have resulted in DTF systems that offer higher resolution prints with vibrant colors that last, making them a compelling alternative to traditional methods. Brands are continuously adapting to these technological shifts, incorporating features that enhance their printing capabilities while simplifying the process for end-users.

Additionally, newer DTF printing machines are becoming more user-friendly, providing integrated solutions that cater to both seasoned printers and novices alike. With intuitive interfaces and support resources readily available, anyone can learn to produce high-quality prints. Such innovations not only democratize the capabilities of fabric decoration but also ensure that the industry remains accessible and competitive.

Accessibility of DTF Transfers for Small Businesses

The accessibility of DTF printing technology has transformed the landscape for small business owners and crafters. As resources and instructional content become more widespread, individuals are empowered to adopt DTF methods with confidence. This influx of information allows for a greater understanding of the process, from selecting the right materials to mastering the application techniques necessary for creating professional-quality prints.

Moreover, the rise of online platforms offering DTF printers, films, and inks at competitive prices has made it feasible for small-business owners to incorporate this technology into their operations without substantial upfront investments. The reduced barrier to entry enables more entrepreneurs to enter the custom garment market, fostering creativity and innovation within the community.

Challenges Associated with DTF Transfers

While DTF transfers present numerous advantages, they are not without their challenges. Longevity is a key concern among users, as some have reported issues related to the durability of the transfers when subjected to various washing conditions. Unlike traditional methods that typically provide robust longevity, these new transfers require careful handling and laundering practices to ensure that the high-quality prints do not fade or peel over time.

Additionally, understanding the removal process for DTF prints remains an area of concern for many users. Should there be a need for removal, it is crucial to learn how to handle the task without damaging the substrate fabric. As with any printing method, mastering these aspects is essential for minimizing waste and maintaining the integrity of the garments.

Comparing DTF Transfers to Traditional Printing Methods

DTF transfers have emerged as a potent competitor to traditional printing methods like screen printing and heat transfer. While traditional methods have been the industry standard for years, they often come with higher material waste and longer turnaround times. DTF technology mitigates these issues by allowing for quick production cycles and precise ink application, making it a more attractive option for contemporary garment printing.

Furthermore, the quality of prints achieved through DTF surpasses that of many traditional techniques, particularly for complex designs. With the ability to produce intricate graphics and vivid colors, DTF printing appeals to brands looking to differentiate themselves in a crowded market. As businesses weigh their options, the benefits of adopting DTF are becoming increasingly clear, positioning it favorably in the ongoing evolution of printing technologies.

Frequently Asked Questions

What are DTF transfers and how do they differ from traditional printing methods?

DTF transfers, or Direct-to-Film transfers, utilize advanced digital printing technology to print designs onto a film, which is then applied to fabric using heat and pressure. Unlike traditional printing methods like screen printing, which involve labor-intensive processes and physical screens, DTF allows for superior vibrancy, detailed prints, and greater efficiency, resulting in lower waste and higher-quality outputs.

How is DTF printing sustainable compared to traditional printing methods?

DTF printing is considered more sustainable because it minimizes waste by using precise amounts of ink and materials, significantly reducing excess associated with traditional methods like screen printing. This eco-friendly approach aligns with increasing consumer demand for environmentally responsible practices in garment production.

What are the innovations in DTF printing technology that enhance product quality?

Recent innovations in DTF printing technology include enhancements in vibrancy and durability, allowing for intricate designs and vibrant imagery. Unlike traditional methods, DTF prints can achieve high-quality results with diverse color choices and fine details, making them suitable for complex designs that traditional printing struggles to replicate.

Is it easier for non-professionals to use DTF transfers compared to traditional printing methods?

Yes, DTF transfers are becoming more user-friendly, enabling hobbyists and small business owners without extensive printing experience to create high-quality designs easily. Comprehensive educational resources are emerging to guide users through the DTF process, making it more accessible to a wider audience.

What challenges do users face when working with DTF transfers?

Some challenges associated with DTF transfers include concerns about the longevity of prints and their removal processes. Users often face questions regarding how well DTF prints hold up over time and how to safely remove them from fabric without causing damage, underscoring the importance of understanding product lifecycle management.

How can brands benefit from adopting DTF printing technology in their production processes?

Brands that adopt DTF printing technology benefit from increased operational efficiency and reduced environmental impact due to lower waste. Additionally, the ability to produce high-quality, vibrant designs appeals to eco-conscious consumers, positioning brands favorably in a competitive market that values sustainability and innovation.

| Key Points | DTF Transfers | Traditional Methods |

|---|---|---|

| Definition | Utilizes digital printing technology to apply designs on fabric via a film. | Involves physical screens to transfer ink onto fabric. |

| Sustainability | Minimizes ink and material waste, making it more eco-friendly. | Often produces considerable ink waste, less eco-friendly. |

| Product Quality | Offers superior vibrancy and detail, better for complex designs. | Limited by screen printing capabilities in color and detail. |

| Accessibility | Easier for hobbyists and small businesses to use with available resources. | More technical with a steeper learning curve. |

| Challenges | Concerns with print longevity and ease of removal. | Mature technology but still has its complexities. |

Summary

DTF Transfers present an innovative solution in the realm of fabric printing, offering users an eco-friendly alternative to traditional methods. Through advanced digital technology, DTF allows for vibrant and detailed prints which not only enhance the quality of apparel decoration but also significantly reduce waste in production. Its rising accessibility ensures that both hobbyists and small business owners can easily adopt this technique, although challenges concerning print durability and removal require careful consideration. As the garment decoration industry continues to evolve, DTF Transfers stand poised to lead the charge towards more sustainable and efficient practices.