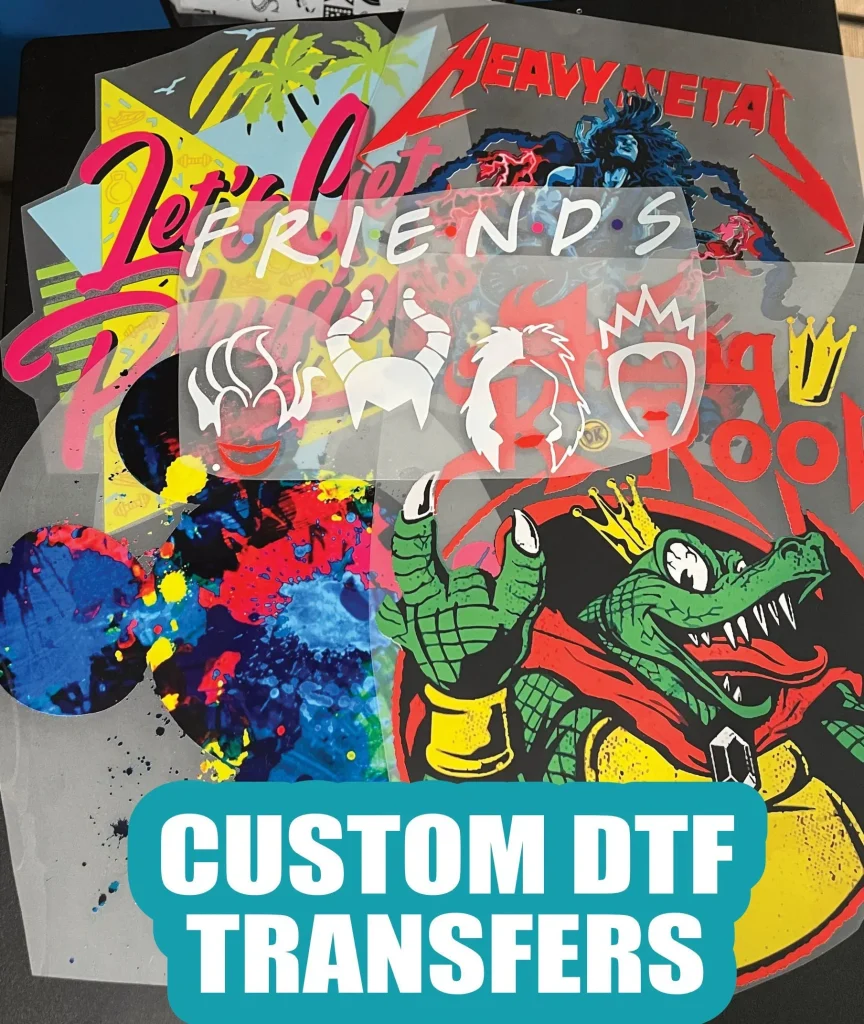

DTF transfers are at the forefront of custom apparel printing, introducing a game-changing approach to textile design that amateurs and professionals alike are embracing. This innovative process, known as Direct-to-Film (DTF) printing, utilizes advanced techniques to achieve vibrant images on various fabrics, making it an excellent choice for custom garment creation. For beginners diving into the world of DTF transfers, grasping the fundamental aspects of this printing method can lead to stunning results that set their creations apart. As we explore DTF transfers, we’ll uncover essential tips and a detailed overview of the DTF transfer process, helping you navigate this exciting terrain of printing. By mastering these concepts, you’ll be well on your way to producing high-quality custom designs that captivate your audience.

Welcome to the exciting realm of direct-to-film printing, a revolutionary technique reshaping the future of custom fabric designs. This method not only enhances the quality of prints but also allows for creative freedom across various textile applications. If you’re a newcomer looking to explore this dynamic field, understanding the fundamentals of the direct-to-film transfer process will be essential for your success. We’ll cover everything from basic DTF printing tips to the tools needed for effective application, ensuring that you’re equipped to create stunning custom apparel. As you embark on this journey, you’ll find that mastering direct-to-film techniques can unlock numerous opportunities in the world of custom printing.

Understanding DTF Printing: A Beginner’s Overview

Direct-to-Film (DTF) printing is a cutting-edge method for creating high-quality designs on fabric. It involves printing your artwork onto a special film, which is then heat-transferred onto garments. This technique has gained popularity due to its flexibility and ability to produce vibrant, durable prints on various materials including cotton, polyester, and blends. For those new to custom apparel printing, grasping the essentials of DTF is vital to ensuring that your projects look professional and hold up well to wear and washing.

One of the key advantages of DTF printing is its versatility. Unlike traditional screen printing, which can be limited by color and fabric type, DTF allows for intricate designs and a wide range of colors to be printed simultaneously. This is particularly beneficial for small businesses or hobbyists looking to offer custom apparel. Additionally, since DTF transfers can be applied to various garments with ease, it opens up a world of creative possibilities for graphic designers and entrepreneurs alike.

Essential Tools for Effective DTF Transfers

To start your DTF printing journey, you need specific equipment and materials. A high-quality inkjet printer that can handle DTF inks is crucial for producing clear and colorful designs. Look for models that allow for dual ink applications, particularly CMYK and white inks, as these will be essential in achieving the desired print quality and opacity.

In addition to the printer, you’ll require specialized DTF transfer film and adhesive powder. The quality of the transfer film directly impacts the final product—it’s worth investing in reputable brands to ensure a smooth transfer process. After printing your design, the adhesive powder acts as a bonding agent during the heat application stage, thus, getting quality adhesive powder is equally important for achieving durable and long-lasting prints.

Step-by-Step Guide to the DTF Transfer Process

The DTF transfer process can be broken down into several manageable steps. First, you need to create your design using graphic design software. Ensure your artwork is print-ready, paying careful attention to color selections, sizing, and layering, as these elements will determine how your final product looks.

Once your design is ready, print it onto the DTF film with your inkjet printer. It’s important to adjust printer settings to avoid issues like color misalignment or blurriness. After printing, sprinkle the adhesive powder over the wet ink for optimal adhesion during heat transfer. Finally, cure the design using a heat gun or curing oven before applying it to fabric with a heat press—this ensures a strong bond and vibrant finish.

Key Tips for Success with DTF Printing

For beginners venturing into DTF printing, following best practices is crucial for achieving quality results. Start by calibrating your printer to ensure color accuracy and consistency throughout your prints. It may also be helpful to conduct test runs on scrap fabric before diving into your main projects—this allows you to refine your technique without the stress of wasting materials.

Additionally, investing in high-quality materials such as reliable inks, films, and adhesive powders cannot be overstated. They significantly influence the final result of your prints, so opting for premium options is a wise decision to enhance your workflow and end products. Regular maintenance of your printer and heat press will also support consistent quality over time.

Current Trends in DTF Printing

The landscape of DTF printing is evolving rapidly, with new technological advancements making the method more accessible. Recently, more affordable DTF printers have emerged on the market, catering specifically to beginners and entrepreneurs. These machines come with user-friendly features, allowing for a seamless entry into the world of custom apparel printing.

Another trend is the rise of all-in-one DTF starter kits that include everything a novice needs to get started—from printers and films to adhesives and heat presses. These kits simplify the setup process, making it easier for newcomers to familiarize themselves with the DTF transfer process and focus on developing their creative skills.

Expanding Your DTF Printing Knowledge

As you delve deeper into the DTF printing world, consider exploring various learning resources available online. Tutorial videos on platforms like YouTube provide step-by-step guides, showcasing every facet of the DTF process from design creation to the finishing touch on garments. These visual aids can significantly enhance your understanding and skills.

Engaging with online communities is another excellent way to expand your DTF printing knowledge. Joining forums or social media groups can connect you with fellow enthusiasts who share tips, experiences, and advice. Networking within these communities can facilitate discussions about trends, troubleshoot challenges, and motivate you to experiment with new designs and techniques.

Frequently Asked Questions

What is the DTF transfer process in custom apparel printing?

The DTF transfer process involves printing your design onto a special film using an inkjet printer, applying adhesive powder to the wet ink, curing the design, and then heat pressing it onto the fabric. This method is favored for its versatility across various fabrics and producing vibrant, detailed prints.

What do I need to get started with DTF printing?

To start DTF printing, you need a compatible inkjet printer, DTF transfer film, adhesive powder, and a heat press or curing oven. Investing in high-quality materials is crucial for achieving professional-looking results in custom apparel printing.

What are some helpful tips for beginners using DTF transfers?

For beginners, it’s important to calibrate your printer for accurate colors, conduct test runs on scrap fabric to fine-tune settings, invest in quality materials, and maintain your equipment regularly. These practices can significantly enhance the quality of your DTF transfers.

Can DTF transfers be used on all types of fabric?

Yes, DTF transfers can be applied to a wide range of fabrics including cotton, polyester, and blends. This versatility makes DTF printing an excellent choice for custom apparel in various applications.

What distinguishes DTF printing from other printing methods?

DTF printing stands out due to its ability to print vibrant, detailed designs directly onto a film that can adhere to various textiles. Unlike some other methods, DTF allows for better color vibrancy and works with a broader range of materials, making it particularly appealing for custom apparel printing.

Are there any trends in DTF printing that beginners should know?

Currently, trends in DTF printing include the emergence of more affordable DTF printers and comprehensive starter kits designed for beginners. These developments make it easier for newcomers to enter the world of DTF transfers and unleash their creativity in custom garment printing.

| Key Points | Details |

|---|---|

| What Are DTF Transfers? | DTF printing applies inks on a special film to be heat-pressed onto various fabrics, making it versatile for custom apparel. |

| Essential Equipment | Key tools include a quality inkjet printer, DTF transfer film, adhesive powder, and a heat press or curing oven. |

| The Transfer Process | 1. Create design; 2. Print on DTF film; 3. Apply adhesive powder; 4. Cure the design; 5. Heat transfer to fabric. |

| Tips for Success | Calibrate printer, conduct test runs, invest in quality materials, and maintain equipment regularly. |

| Trends and Developments | Affordable DTF printers and starter kits are emerging, making the process more accessible for beginners. |

| Learning Resources | Utilize tutorial videos and engage in online communities for support and further understanding of DTF printing. |

Summary

DTF Transfers have become a game-changer in the custom printing industry, offering an innovative way for both professionals and hobbyists to create vibrant designs on fabrics. As you explore the world of DTF, understanding the essentials—from the equipment needed to the detailed transfer process—is key to achieving outstanding results. By focusing on high-quality materials and continuous learning, novices can effectively harness the power of DTF Transfers and embark on a successful printing journey.