UV DTF Transfer is an innovative transfer method for custom apparel that blends direct-to-film workflow with UV-curable inks to create vibrant designs. This approach delivers rich color and detailed imagery while remaining compatible with a wide range of fabrics, expanding the options beyond traditional garment printing techniques. Compared with classic DTF printing and UV printing vs sublimation, sublimation printing remains a benchmark for color saturation on appropriate polyester substrates. Designs can range from photo-realistic artwork to logos, making it suitable for fashion, promotional items, and customized gifts. Understanding the strengths and limitations of UV DTF Transfer helps you decide when it fits your fabric, budget, and production goals.

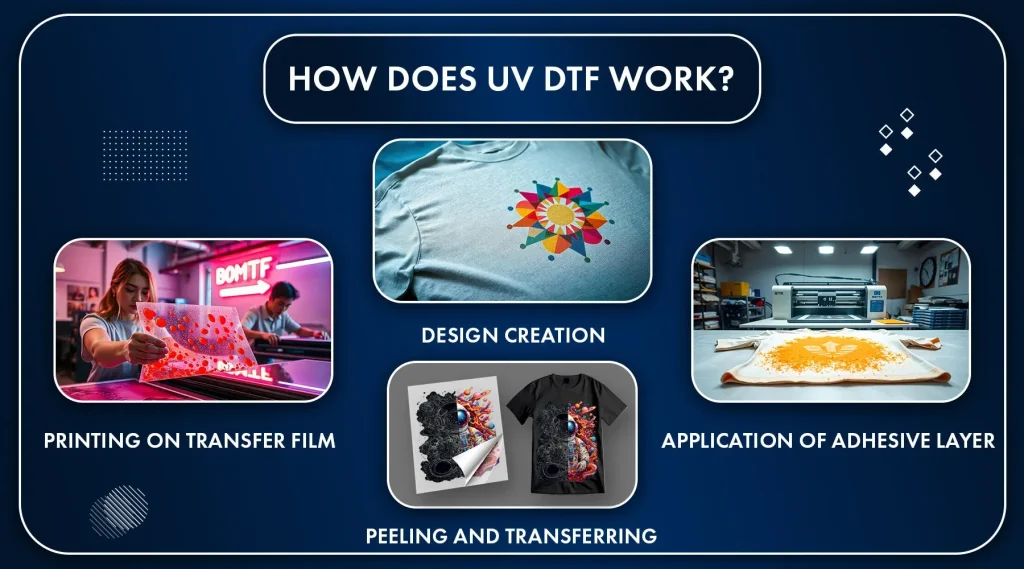

Put simply, this UV-curable direct-to-film process uses UV inks on a transfer film that is heat-pressed onto fabrics, delivering bold, full-color designs. Seen through an LSI lens, it can be described as a UV-curable transfer technique and a versatile garment printing techniques option that complements other methods. Related concepts like DTF printing, UV printing, sublimation printing, and other garment printing techniques help search engines connect this topic with neighboring ideas. Ultimately, the best choice depends on fabric type, color needs, and order size. Using these alt terms in content improves discoverability for readers comparing print methods and exploring on-demand customization.

UV DTF Transfer: A Flexible Garment Printing Technique Across Fabrics

UV DTF Transfer uses UV-curable inks printed onto a transfer film, which is then heat-pressed onto textiles. This approach blends aspects of traditional DTF workflows with UV printing technology to produce vibrant, full-color designs and fine details. Because of this combination, UV DTF transfers can be suitable for a wide range of base materials, from cotton blends to polyesters, depending on the inks and films used. In the broader landscape of garment printing techniques, it sits alongside DTF printing and other UV-based processes as a versatile option for color-rich artwork.

For designers and shops, UV DTF Transfer offers strong color reproduction, good gradient control, and the ability to handle photo-like imagery. It is particularly advantageous for small-to-medium runs where setup speed and on-demand capability matter, and it supports a broader product lineup beyond pure polyester. While the hand feel and wash durability can vary by fabric and adhesive choice, the method generally enables efficient color management and quick turnaround for customized apparel and accessories.

DTF Printing vs Sublimation: Comparing Garment Printing Techniques

DTF printing, including UV-assisted variants, prints designs on a film that is later transferred to fabric with heat and adhesive, enabling full-color, image-heavy graphics on many fabrics. Sublimation printing, by contrast, relies on heat to embed dyes into polymer fibers, delivering bright colors and a soft hand on polyester-based substrates. When comparing UV DTF Transfer and sublimation, substrate compatibility and finish are the most noticeable differences, with DTF offering broader fabric versatility and sublimation excelling on polyester.

For cotton and cotton-blend garments, DTF printing often performs reliably, while sublimation is typically the best choice for all-polyester lines and large-area color coverage. Dark fabrics under sublimation can require white underbases or additional workflows, adding a layer of complexity. Understanding these distinctions helps guide decisions in garment printing techniques based on fabric mix, color needs, and production volume.

Sublimation Printing: Substrates, Color Range, and Fabric Considerations

Sublimation printing uses sublimation dyes that bond with polymer-coated or polyester fabrics when heat and pressure are applied. This process delivers vibrant, saturated colors and a soft, “hand” feel because the print becomes part of the fabric. It is particularly well-suited for high-color, full-coverage designs and large-format graphics on polyester substrates, making it a staple in many garment printing techniques portfolios.

However, sublimation has fabric limitations. It performs best on polyester-based materials and is less effective on cotton or blends without special coatings or post-processing. Achieving accurate white and color fidelity on dark fabrics can require pre-treatments or alternative workflows, which adds steps and cost. These substrate considerations are central to choosing sublimation as the preferred method for specific product lines.

UV Printing vs Sublimation: Durability, Feel, and Workflow

Durability and hand feel differ between UV DTF transfers and sublimation. Sublimation tends to produce a softer hand on polyester, with the color embedded in the fabric, resulting in enduring vibrancy on compatible substrates. UV DTF transfers offer strong durability across a wider range of fabrics, though the perceived hand feel can vary depending on the substrate and adhesive layer.

In terms of workflow, sublimation is often straightforward on suitable fabrics but can require additional steps for dark fabrics or non-polyester materials. UV printing and UV DTF transfers require efficient color management, proper curing hardware, and careful calibration to maintain consistency. Maintenance costs and equipment considerations—such as UV-curable inks, curing units, and film compatibility—also influence long-term viability and operation efficiency.

Choosing Between UV DTF Transfer and Sublimation for Small Runs and Big Projects

For small-to-medium runs and product mixes that include cotton, blends, or non-poly fabrics, UV DTF Transfer offers flexibility and on-demand capability that can be cost-efficient without committing to large-format sublimation equipment. Its color gamut and detailed reproduction make it well-suited for intricate artwork and photography within a compact production setup, aligning with various garment printing techniques.

Large-volume projects on polyester or polyester-coated materials often favor sublimation due to cost-per-unit advantages and seamless color integration. When planning a production strategy, consider design complexity, substrate variety, moisture and heat behavior, and anticipated wash cycles. This helps determine whether UV DTF Transfer or sublimation best meets the goals of speed, durability, and overall value.

Practical Tips: Testing, Pre-Treatments, and Maintenance for Best Results

A practical approach is to test thoroughly before committing to a run. Print test sheets on representative fabrics to validate color accuracy, texture, and adhesion for UV DTF transfers or sublimation on targeted materials. This testing phase supports reliable color management and helps you identify any substrate-specific pretreatments or coatings needed for optimal results.

Pay attention to material compatibility, heat press settings, and post-press care. Verify that you’re using compatible films, inks, and adhesives, and follow supplier guidelines for temperatures and dwell times. After production, provide clear washing instructions to customers to maximize durability, especially for UV DTF transfers on non-poly fabrics, and plan ongoing maintenance for UV-curable systems and curing hardware to sustain performance over time.

Frequently Asked Questions

What is UV DTF Transfer and how does it compare to sublimation printing?

UV DTF Transfer uses UV-curable inks printed on a transfer film that is heat pressed onto fabric, enabling vibrant, full-color designs on a wide range of textiles. Sublimation printing embeds dye into polyester fibers, producing a soft hand and long-lasting color on polyester or polymer-coated substrates. For garment printing techniques, UV DTF often offers greater fabric versatility, while sublimation excels on all-polyester runs.

Which fabrics work best with UV DTF Transfer versus sublimation printing?

UV DTF Transfer works well on cotton blends and many synthetics, expanding options beyond polyester. Sublimation performs best on polyester and poly-coated fabrics, delivering bright, durable color on those substrates.

How durable are UV DTF transfers in washing compared with sublimation?

Durability depends on inks, film, and fabric. Sublimation generally offers excellent wash durability on polyester because the color is embedded in the fibers. UV DTF durability can be strong on many fabrics but may vary by substrate and care; testing on target materials is recommended.

What are the cost and setup considerations when choosing UV DTF printing over sublimation?

UV DTF requires UV ink and curing equipment, which can have higher upfront costs and ongoing maintenance. Sublimation equipment and supplies are often more affordable to start, especially for polyester-focused projects. For small-to-medium runs, UV DTF can offer quick setup and on-demand flexibility.

Is UV DTF Transfer better for detailed images or photography compared to sublimation?

UV DTF Transfer can reproduce complex, high-detail images and photographs with strong color accuracy, especially on non-poly fabrics. Sublimation offers vibrant colors and smooth gradients on polyester but is more limited on cotton and blends; UV DTF provides broader substrate versatility for garment printing techniques.

What steps should I take to evaluate UV DTF Transfer in my shop?

Start with test prints on representative fabrics to validate color, texture, and adhesion. Check film, ink, and adhesive compatibility; determine suitable heat-press settings and any pretreatments. Run small batches, inspect wash durability, and gather customer feedback to guide your choice between UV DTF and sublimation.

| Topic | Key Points |

|---|---|

| UV DTF Transfer | – Direct-to-film transfer using UV-curable inks; prints on transfer film and is applied with heat/pressure. – Blends aspects of traditional DTF with UV printing for vibrant, durable transfers. – Good for full-color, photo-realistic images and intricate graphics; versatile across fabrics depending on inks/films. |

| Sublimation | – Heat-transfer process using sublimation dyes embedded into polymer-coated or polyester fabrics. – Dyes convert to gas and bond with fibers; vibrant, durable print integrated into the fabric. – Best on polyester/poly-coated substrates; less effective on cotton without pretreatment. |

| Pros of UV DTF Transfer | – Color richness and detail for complex images. – Fabric versatility across cotton blends and some synthetics. – Cost-effective for small to medium runs with quick setup. – Easy color management and consistent results across runs. – Quick setup and on-demand suitability. |

| Cons of UV DTF Transfer | – Higher equipment and maintenance costs for UV inks and curing systems. – Substrate performance depends on ink/film/adhesive; some fabrics need pretreatments. – Potential stiffer hand on certain fabrics. – Durability in washing varies with fabric and conditions; testing advised. – More technical color management and calibration needed. |

| Use Cases for UV DTF Transfer | – Full-color apparel and accessories with high detail. – Promotional items with complex artwork. – Small-batch, on-demand orders. – In-store customization where quick turnarounds are valuable. |

| Sublimation: When It Excels | – Polyester-first fabrics and polymer-coated substrates. – Soft, nearly invisible hand on prints. – Large-area color coverage across fabrics. – Cost-effective per unit for high-volume runs on compatible fabrics. |

| Cons of Sublimation | – Limited on cotton and many blends; polyester-focused. – Requires polyester-based substrates or coatings; limited product choices. – Color fidelity on dark fabrics can require white underbases. – Large-format equipment and media costs can be high. |

| Comparing UV DTF Transfer and Sublimation | – Color capability: UV DTF is flexible on non-poly fabrics; sublimation excels on polyester with seamless integration into the fabric. – Feel and durability: Sublimation often yields a softer hand on polyester; UV DTF offers durable results across more fabrics but hand varies by substrate. – Setup/workflow: Sublimation is straightforward on compatible fabrics; UV DTF may require more maintenance/calibration. – Cost: Sublimation is typically cheaper per piece for large polyester runs; UV DTF can be more economical for small-to-mid runs across diverse fabrics. |

| Choosing Between UV DTF Transfer and Sublimation | – Fabric composition: UV DTF is better for cotton, blends, and non-poly fabrics; sublimation is best for all-polyester lines. – Design requirements: UV DTF handles heavy detail and photography across diverse fabrics; sublimation is ideal for large polyester areas. – Turnaround and volume: UV DTF suits frequent small orders; sublimation suits high-volume runs. – Durability and care: Test on target fabrics to assess long-term performance. |

| Practical Tips for UV DTF Transfer and Sublimation | – Test thoroughly with representative fabrics before full runs. – Verify compatible films, inks, and adhesives for the chosen fabric. – Consider pretreatments or coatings where needed. – Optimize heat press settings; follow supplier guidelines and adjust via tests. – Provide clear care instructions to preserve durability. |

| Cost, Durability, and Practical Considerations | – Upfront costs: UV DTF equipment/consumables vs. typically lower starting costs for sublimation. – Running costs: Inks/dyes, films, substrates, energy use; dye-sub is often economical for large runs; UV DTF varies with maintenance. – Durability: Both methods can be durable with proper execution; performance depends on fabric, care, and materials. |

Summary

Table summarizes the key points from the base content comparing UV DTF Transfer and Sublimation, including definitions, pros/cons, use cases, and practical considerations for choosing the right method.